Method for preparing high-purity lysophosphatidylcholine

A phosphatidylcholine, high-purity technology, applied in the field of preparation of phospholipid metabolites, can solve the problems of high comprehensive preparation cost, limited extraction efficiency, difficult to completely remove, etc., and achieve low comprehensive cost, high production efficiency and high yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

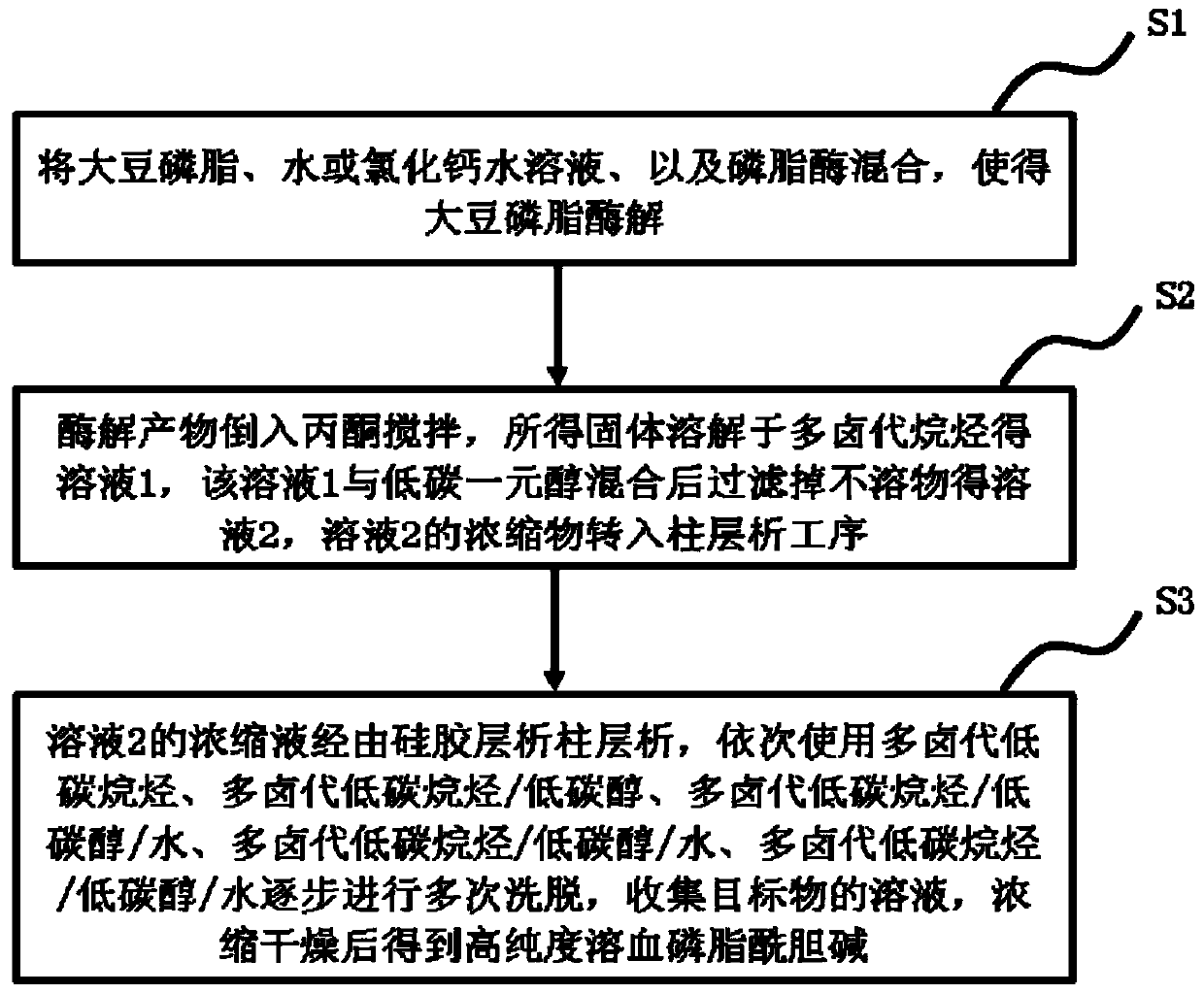

Method used

Image

Examples

Embodiment 1

[0044] In this example, 1.26 g of solid lysophosphatidylcholine with a purity of 99.6% was prepared from 20 grams of powdered soybean lecithin (with a phosphatidylcholine content of 23%) as raw material. specific:

[0045] (1) Add the powdered soybean lecithin and 38 grams of water into a 250 ml round-bottomed reaction bottle equipped with a Teflon mechanical stirring rod, and stir at 50° C. for 30 minutes to obtain an emulsion of soybean lecithin; 0.04 grams of phospholipase A1 Dissolve in 2 grams of water, then add dropwise into the emulsion of phospholipid and water within two minutes, keep warm at 50°C and continue stirring for 3 hours;

[0046] (2) Cool down to room temperature, add 200 ml of acetone under stirring and continue to stir at high speed for 2 hours; stop stirring and filter to separate the solid, which is dissolved in 60 ml of chloroform to obtain a solution; the solution is poured into 300 ml of methanol neutralize and stir vigorously; remove the formed sol...

Embodiment 2

[0049] In this example, 0.54 g of solid lysophosphatidylcholine with a purity of 99.1% was prepared from 20 grams of liquid soybean lecithin (with a phosphatidylcholine content of 11%) as a raw material. specific:

[0050] (1) Add the liquid soybean lecithin and 38 g of water into a 250 ml round-bottomed reaction bottle equipped with a Teflon mechanical stirring rod, and stir at 50°C for 30 minutes to obtain an emulsion; 0.04 g of phospholipase A1 is dissolved in 2 gram of water, and then dropwise added to the emulsion of phospholipid and water within two minutes, kept stirring at 50°C for 2 hours;

[0051] (2) Cool down to room temperature, add 200 ml of acetone under stirring and continue to stir at high speed for 2 hours; stop stirring and filter to separate the solid, which is dissolved in 60 ml of dichloroethane to obtain a solution; the solution is poured into 300 ml in isopropanol and vigorously stirred; the formed solid insolubles were removed by filtration, the filtr...

Embodiment 3

[0054] In this example, 1.22 grams of solid lysophosphatidylcholine with a purity of 99.3% was prepared from 20 grams of powdered soybean lecithin (with a phosphatidylcholine content of 23%) as raw material. specific:

[0055] (1) Add the powdered soybean lecithin and 58 g of water to a 500 ml round-bottomed reaction bottle equipped with a Teflon mechanical stirring rod, and stir at 50° C. for 30 minutes to obtain an emulsion; 0.03 g of phospholipase A1 is dissolved in 2 gram of water, and then added dropwise to the emulsion of phospholipids and water within two minutes, kept stirring at 50°C and continued to react for 4 hours;

[0056] (2) Cool down to room temperature, add 300 ml of acetone under stirring and continue to stir at high speed for 2 hours; stop stirring and filter to separate the solid, which is dissolved in 60 ml of dichloromethane to obtain a solution; the solution is poured into 300 ml of ethanol neutralize and stir vigorously; remove the formed solid insolu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com