Two-end black pig minced pork cutlet and preparing method thereof

A two-headed, pork-based technology, applied in chemical preservation of meat/fish, food ingredients as taste modifiers, food science, etc., can solve problems such as product elasticity, poor cohesion, insufficient protein binding ability, and impact on product taste, etc. Achieve the effect of short time-consuming, high degree of mechanized operation, good application value and market potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

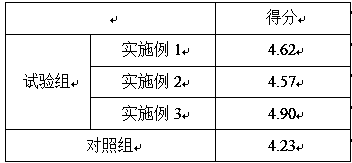

Examples

Embodiment 1

[0020] The two-end black pork cake has the following ingredients and parts by weight: 70 parts of ground two-end black pork, 12 parts of soybean protein isolate, 3 parts of peach gum, 1.5 parts of sodium alginate, 2.0 parts of vegetable oil, and 3.5 parts of pickling agent. The ratio of each component in the two-end black pork cake is reasonable, so that the two-end black pork cake has good flavor, smoothness, tenderness, water and oil retention, elasticity, color stability and storage performance, low fat content, cooking loss and thawing Low loss and low cost.

[0021] The weight ratio of pig fat and pig lean meat in the above-mentioned two-end black pork mince is 1:10. On the one hand, the two-end black pork mince can make the two-end black pork cake have good local flavor, smoothness, tenderness, water retention, elasticity and Cohesion improves the quality of black pork patties at both ends; on the other hand, it reduces the fat content in the patties to meet the needs of...

Embodiment 2

[0031] The two-end black pork cake has the following ingredients and parts by weight: 60 parts of ground two-end black pork, 20 parts of soybean protein isolate, 2 parts of peach gum, 2.5 parts of sodium alginate, 1.5 parts of vegetable oil, and 5.8 parts of pickling agent. The weight ratio of pig fat and pig lean meat in the above-mentioned two black pork minces is 1:8; Vegetable oil is the mixture of sunflower oil, olive oil and rapeseed oil, and its weight ratio is 1:0.9:0.2; Its parts by weight are: 25 parts of starch, 1.5 parts of table salt, 0.4 part of compound phosphate, 2 parts of cooking wine, 0.5 part of monosodium glutamate, 1.4 parts of five-spice powder, 0.7 part of soy sauce, 2 parts of white sugar, 1.6 parts of sucrose, 1.3 parts of xylose, 0.04 part of TG enzyme, 12 parts of ice water; the weight ratio of D-xylose and L-xylose in xylose is 100:0.4.

[0032] The preparation method of the black pork pie with two ends, its specific steps are:

[0033] Soybean pr...

Embodiment 3

[0038] The two-end black pork cake has the following ingredients and parts by weight: 65 parts of two-end black pork mince, 15 parts of soybean protein isolate, 2.5 parts of peach gum, 2 parts of sodium alginate, 1.7 parts of vegetable oil, and 4.5 parts of pickling agent. The weight ratio of pig fat fat and pig lean meat in the above-mentioned two black pork minces is 1:9; Vegetable oil is the mixture of sunflower oil, olive oil and rapeseed oil, and its weight ratio is 1:0.8:0.3; And its parts by weight are: 22 parts of starch, 1.8 parts of table salt, 0.3 parts of compound phosphate, 3 parts of cooking wine, 0.4 parts of monosodium glutamate, 1.5 parts of five-spice powder, 0.6 parts of soy sauce, 2.5 parts of white sugar, 1.4 parts of sucrose, 1.4 parts of xylose, 0.035 parts of TG enzyme, 14 parts of ice water; the weight ratio of D-xylose and L-xylose in xylose is 100:0.3.

[0039] The preparation method of the black pork pie with two ends, its specific steps are:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com