Preparation method of cuprous oxide and tritanium dicarbide heterojunction composite material and application thereof for photocatalytic reduction of carbon dioxide

A technology of trititanium dicarbide and cuprous oxide, which is applied in the directions of carbon monoxide, catalyst activation/preparation, chemical instruments and methods, etc., can solve the problems of low reduction potential and limited catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

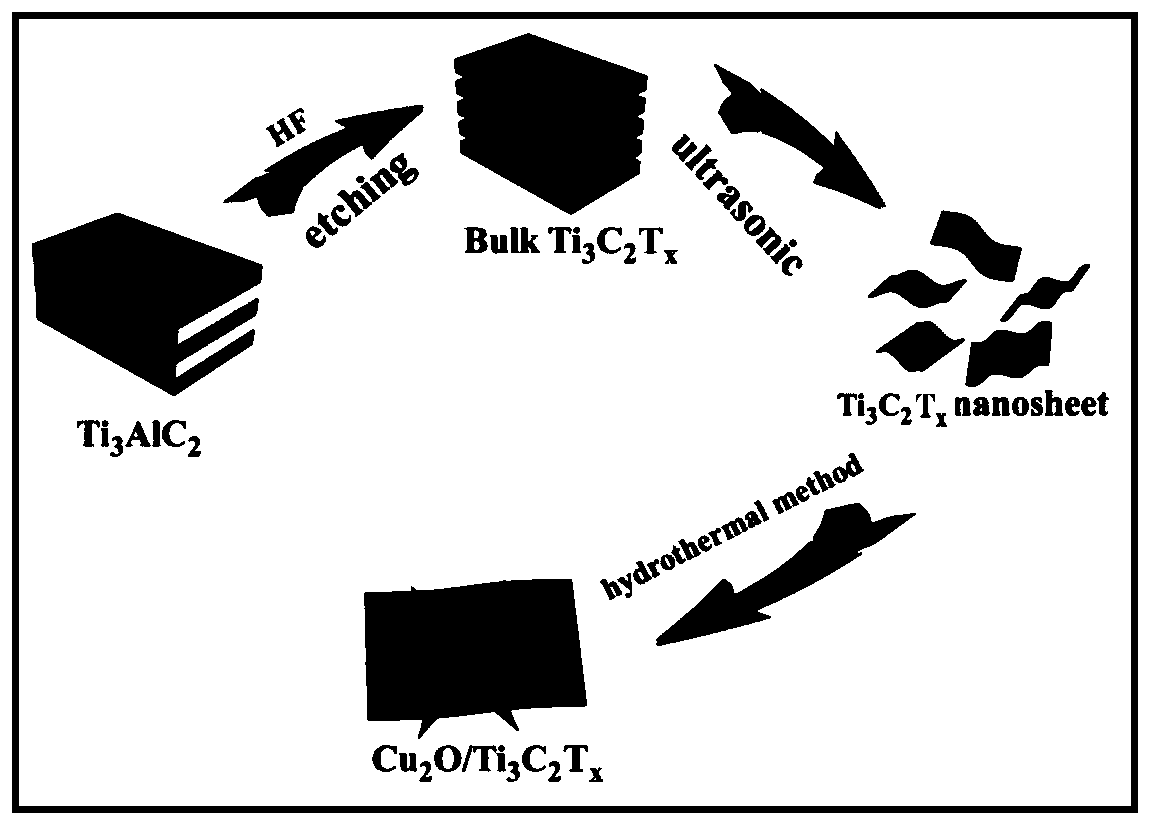

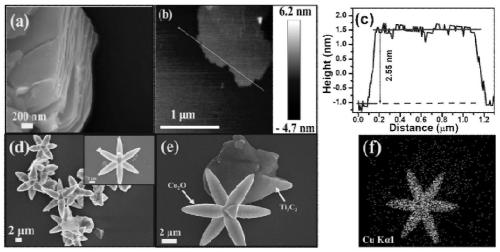

[0025] 1. Etching Ti by HF method 3 AlC 2 , the specific method is: weigh 3g Ti 3 AlC 2 The powder was slowly added to a polytetrafluoroethylene beaker containing 60ml 40% HF solution under magnetic stirring, a small amount several times, and the adding time lasted half an hour to prevent the temperature of the solution from overheating, and the reaction time at room temperature continued for 48h. After the reaction, the black suspension was repeatedly centrifuged with deionized water until the pH was close to neutral, and then put into an oven to dry the sample.

[0026] 2. Carry out peeling treatment to the bulk phase titanium dioxide carbide obtained in step 1, and the specific method of stripping titanium dioxide titanium carbide is as follows: dissolve titanium dioxide titanium carbide powder in 100ml of DMSO solution, and the magnetic stirring time lasts for 24h, and the The way to get solid three titanium carbide again. Weigh 0.1 g of the above-mentioned solid triti...

Embodiment 2

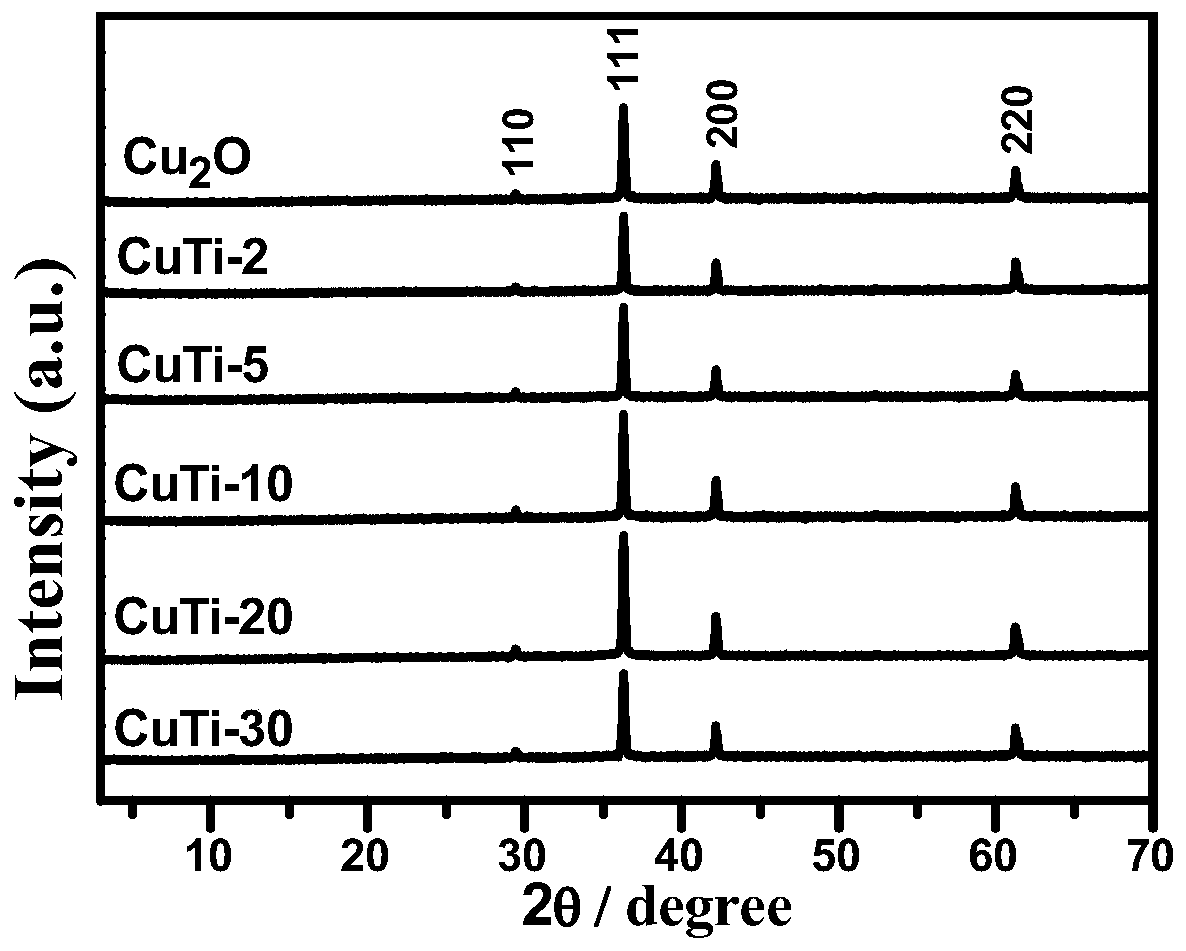

[0031] Weigh 1g of copper acetate and 1.8g of glucose and dissolve them in 75ml of deionized water, and then mix them evenly with the solution of titanium dioxide titanium carbide ultrathin nanosheets obtained in step 2 of 5ml of Example 1, and the other steps are the same as in Example 1 to obtain The catalyst is recorded as CuTi-5.

[0032] The preparation of the CuTi-5 thin film is the same as in Example 1.

[0033] Test CuTi-5 Photoreduction of CO 2 The catalytic performance is the same as that of Example 1.

Embodiment 3

[0035] Weigh 1g of copper acetate and 1.8g of glucose and dissolve them in 70ml of deionized water, and then mix them evenly with 10ml of trititanium carbide ultrathin nanosheet solution. The other steps are the same as in Example 1, and the obtained catalyst is designated as CuTi-10 .

[0036] The preparation of CuTi-10 film is the same as that in Example 1.

[0037] Test CuTi-10 Photoreduction of CO 2 The catalytic performance is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com