Heat management system and new energy automobile with same

A thermal management system and circulation system technology, applied in the field of electric vehicle thermal management system and its control, can solve the problems of complex structure, poor performance, large heat loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] This embodiment takes a heat management system for a motor vehicle as an example.

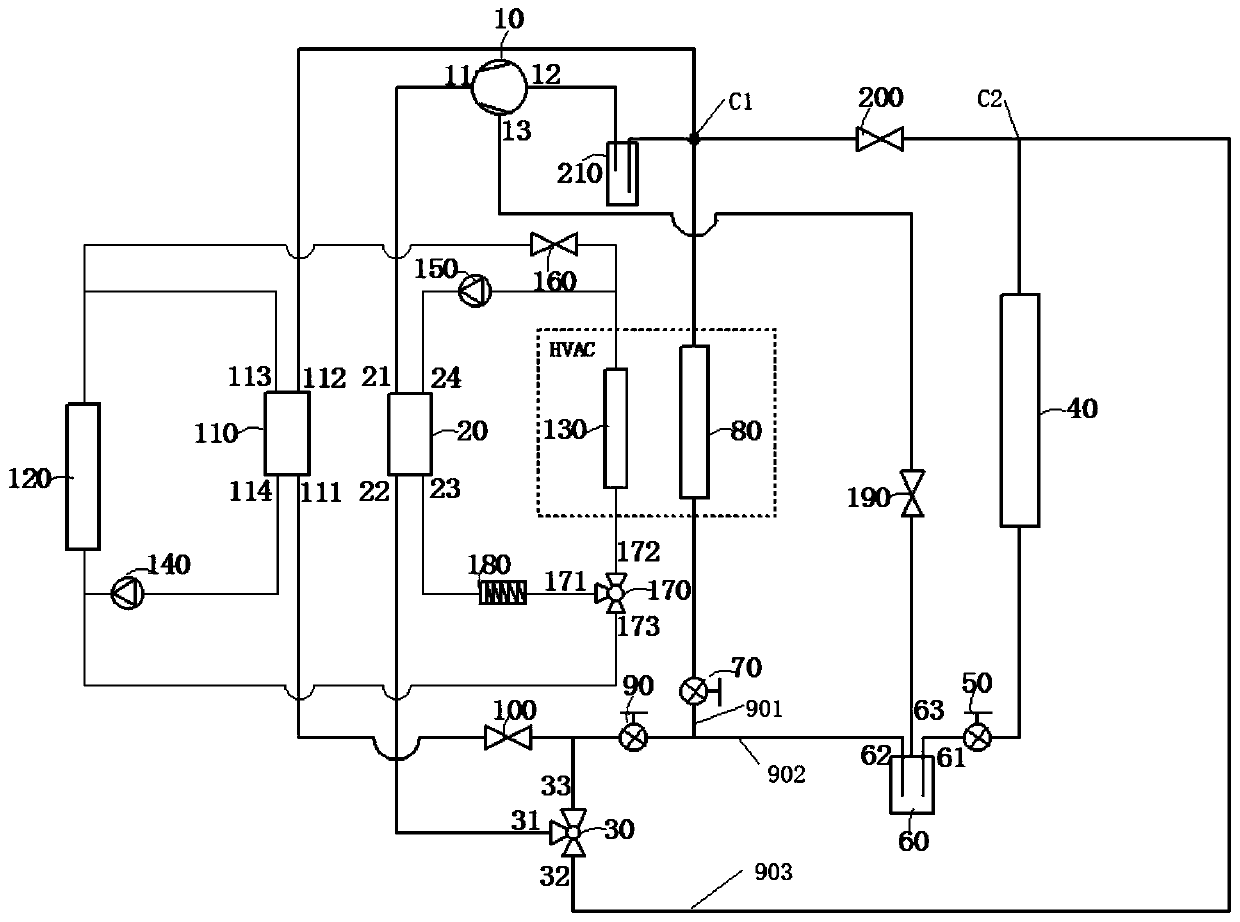

[0057] Such as figure 1 As shown, the electric vehicle thermal management system is mainly composed of a refrigerant circulation system and a coolant circulation system. The refrigerant cycle system is composed of a compressor 10 with intermediate air supply and enthalpy increase, a water-cooled intermediate heat exchanger 20, a first three-way proportional valve 30, an external heat exchanger 40, a first electronic expansion valve 50, a flasher 60, Second electronic expansion valve 70, interior heat exchanger 80, third electronic expansion valve 90, first solenoid valve 100, battery plate heat exchanger 110, fourth solenoid valve 190, second solenoid valve 200, gas-liquid separator 210 and the piping connecting them.

[0058] The compressor exhaust port 11 is connected to the first connection port 21 of the water-cooled intermediate heat exchanger, the second connection port 22 of the...

Embodiment 2

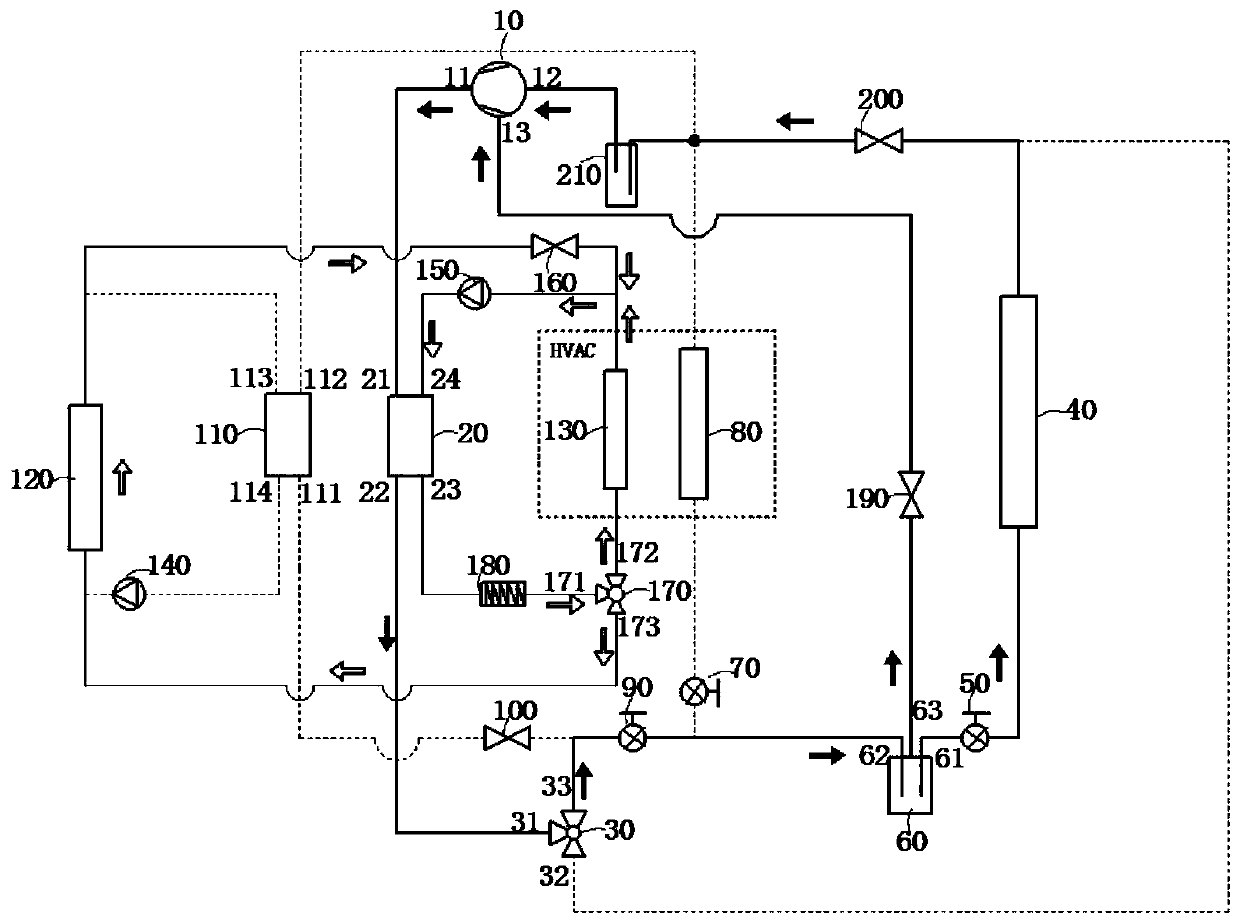

[0069] Based on the same inventive concept, combined with the above-mentioned scheme, such as Figure 1 to Figure 5 As shown, the present invention also provides a control method according to the above electric vehicle thermal management system.

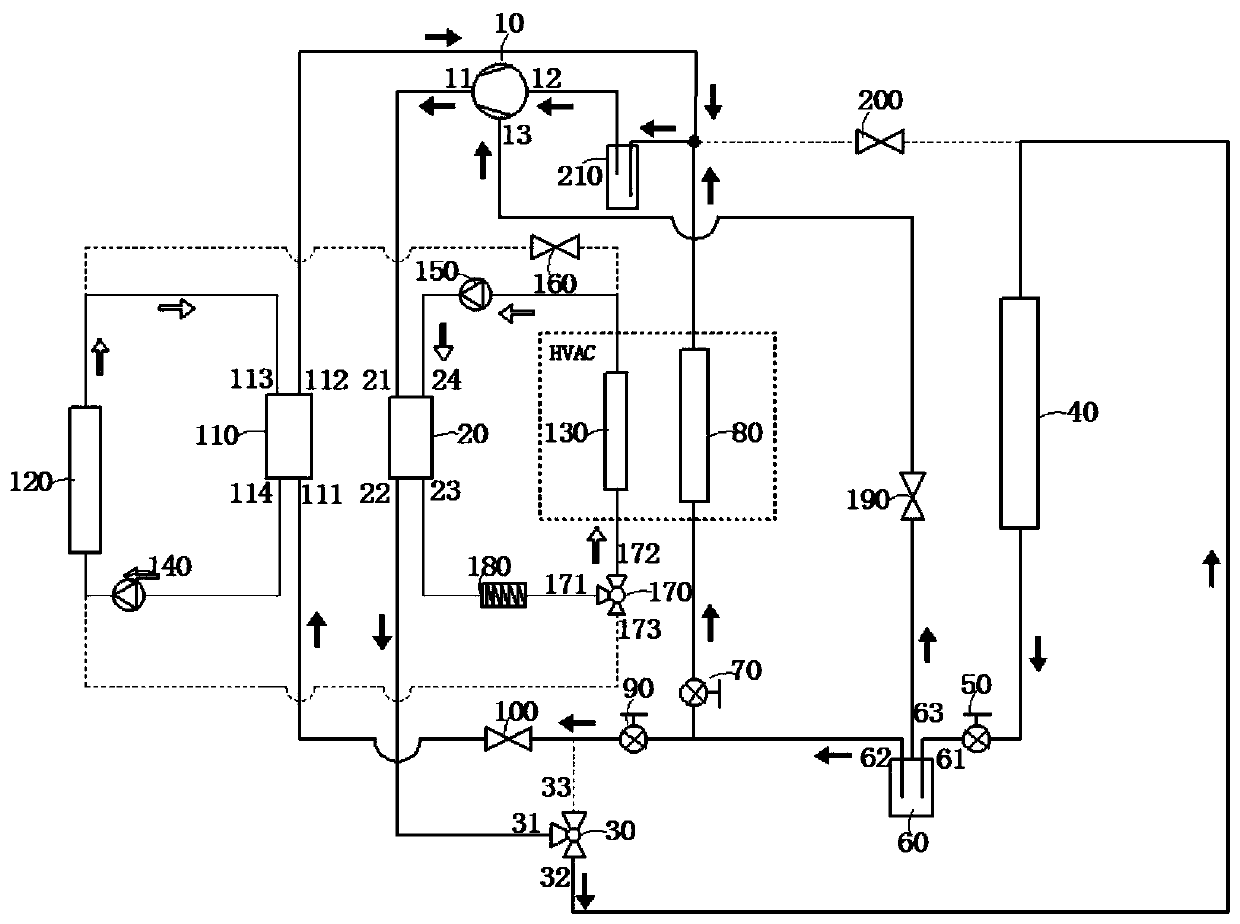

[0070] Such as figure 2 As shown, in summer cooling conditions, the electric vehicle thermal management system of the present invention cools the passenger compartment and the battery at the same time.

[0071] The first port 31 of the three-way proportional valve is connected to the second port 32 of the three-way proportional valve, the first solenoid valve 100 is opened, the fourth solenoid valve 190 is opened, the second solenoid valve 200 is closed, and the first port 171 of the three-way proportional valve is connected to The flow ratio of the second interface 172 of the three-way proportional valve is 100%, and the third electromagnetic valve 160 is closed.

[0072]The high-temperature and high-pressure gaseous superheated ...

Embodiment 3

[0091] A new energy vehicle adopting the above energy management system and management method.

[0092] The foregoing embodiments have the following advantages:

[0093] 1. Through the use of a two-stage enthalpy-increasing compressor with an intermediate air supply port, a matching flasher and a two-stage throttling electronic expansion valve, a two-stage air supply enthalpy increasing system is realized to improve performance under extreme working conditions.

[0094] 2. Through the water-cooled condenser arranged between the compressor exhaust port and the external heat exchanger and the warm air core arranged in the HVAC air-conditioning box, the heat of the refrigerant in the heat pump system is indirectly transferred to the passenger compartment through the coolant Inside.

[0095] 3. The PTC liquid heater arranged in the coolant circulation serves as an auxiliary heating source for heating the passenger compartment and battery.

[0096] 4. Through the heater core and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com