Sulfide nanometer zero-valent iron particle as well as preparation method and application thereof

A nano-zero-valent iron and particle technology, applied in iron sulfide, chemical instruments and methods, inorganic chemistry, etc., can solve the limitations of large-scale production and application of sulfide-type nano-zero-valent iron particles, reduce the selectivity and reduction of target pollutants Conversion efficiency, consumption of large reduction capacity and other problems, to achieve the effect of high reduction conversion efficiency, low production cost and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of sulfurized nano zero-valent iron particle, its preparation method comprises the following steps:

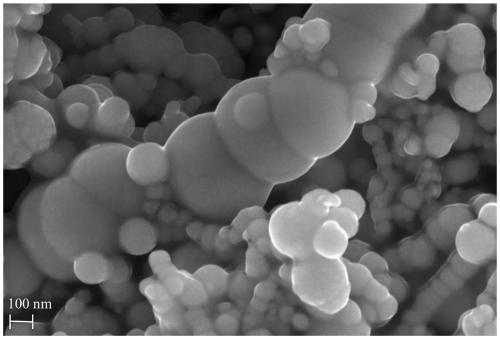

[0034] 1) 60 mL of FeCl with a concentration of 0.2 mol / L 2 The solution was added to the reactor, and 180 mL of NaBH with a concentration of 0.3 mol / L was added while stirring. 4 solution was added dropwise to FeCl 2 In the solution, after the dropwise addition, continue to stir and react for 15 minutes, then let it stand for precipitation, remove the supernatant, and wash the solid product 4 times with high-purity water to obtain nanometer zero-valent iron particles (nZVI);

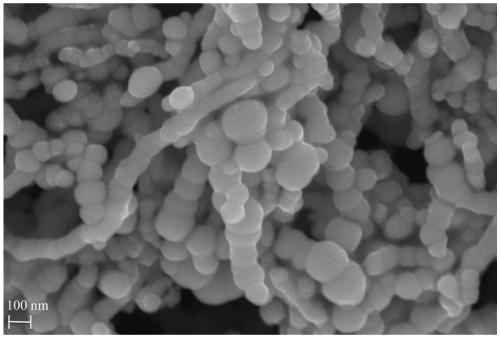

[0035] 2) Disperse the nano-zero-valent iron particles in 420mL of ethanol, then add 0.0096g of elemental sulfur powder (the molar ratio of elemental sulfur powder to nano-zero-valent iron particles is 0.025:1), stir for 12h, and then fully stand, The supernatant was removed, and the solid product was washed 4 times with ethanol to obtain sulfide nano zero-valent iron particles (S-nZVI)....

Embodiment 2

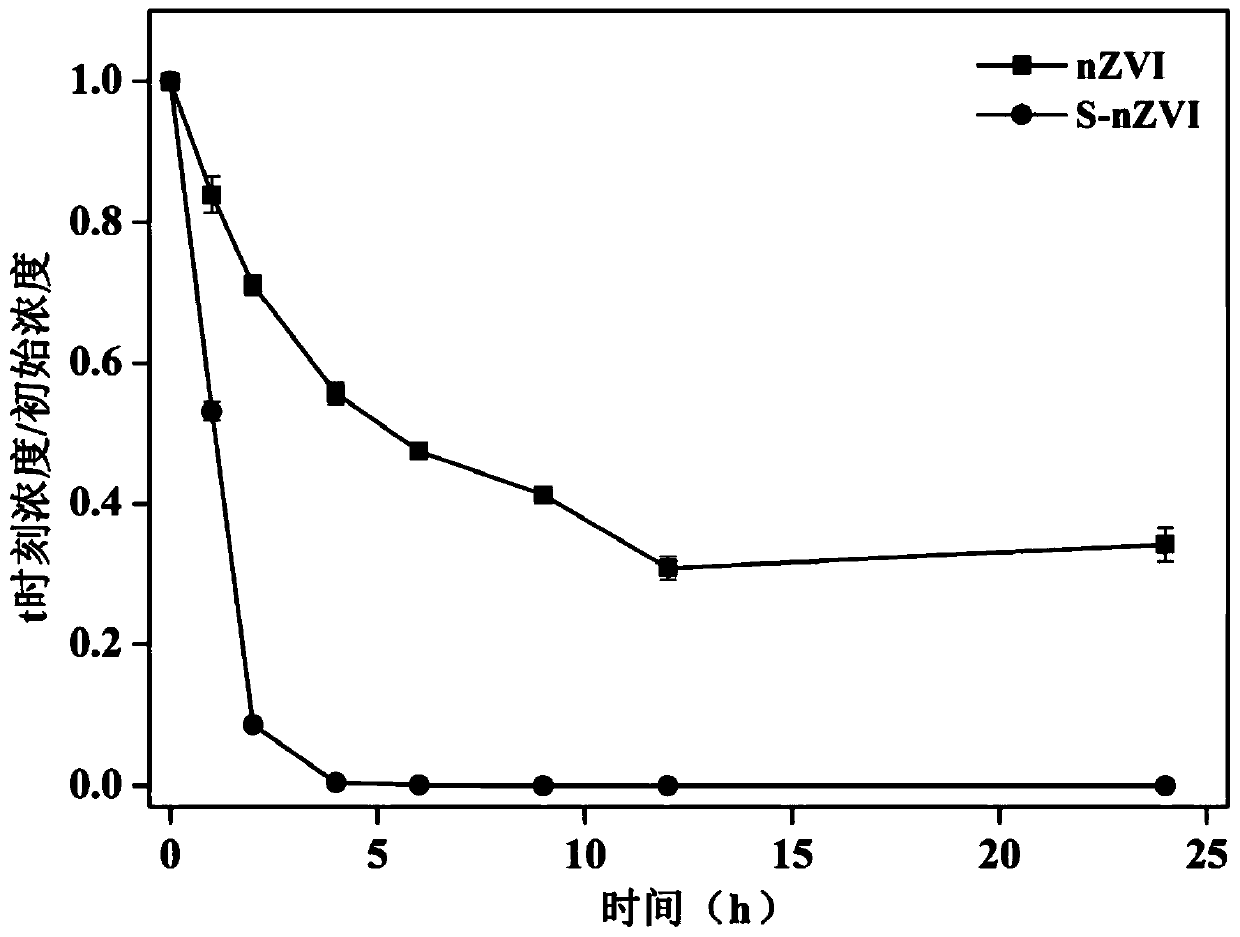

[0050] With reference to the preparation method of Example 1, adjust the mol ratio of elemental sulfur powder and nanometer zero-valent iron particles (abbreviated as S / Fe mol ratio, respectively 0.015:1, 0.025:1, 0.05:1, 0.1:1 and 0.25:1 ), prepare the S-nZVI of different S / Fe mol ratios, then test the degradation effect of the S-nZVI of nZVI and different S / Fe mol ratios on TBBPA with reference to the method of Example 1, test result is as follows Figure 7 shown.

[0051] Depend on Figure 7 It can be seen that when the molar ratio of elemental sulfur powder and nanometer zero-valent iron particles is 0.025:1, the prepared S-nZVI has the best degradation effect on TBBPA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com