Infrared-transmission fluorozirconate glass containing gallium oxide and preparation method of glass

A fluorozirconate, infrared-transmitting technology, used in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of low phonon energy and large atomic mass, and achieve the effect of high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

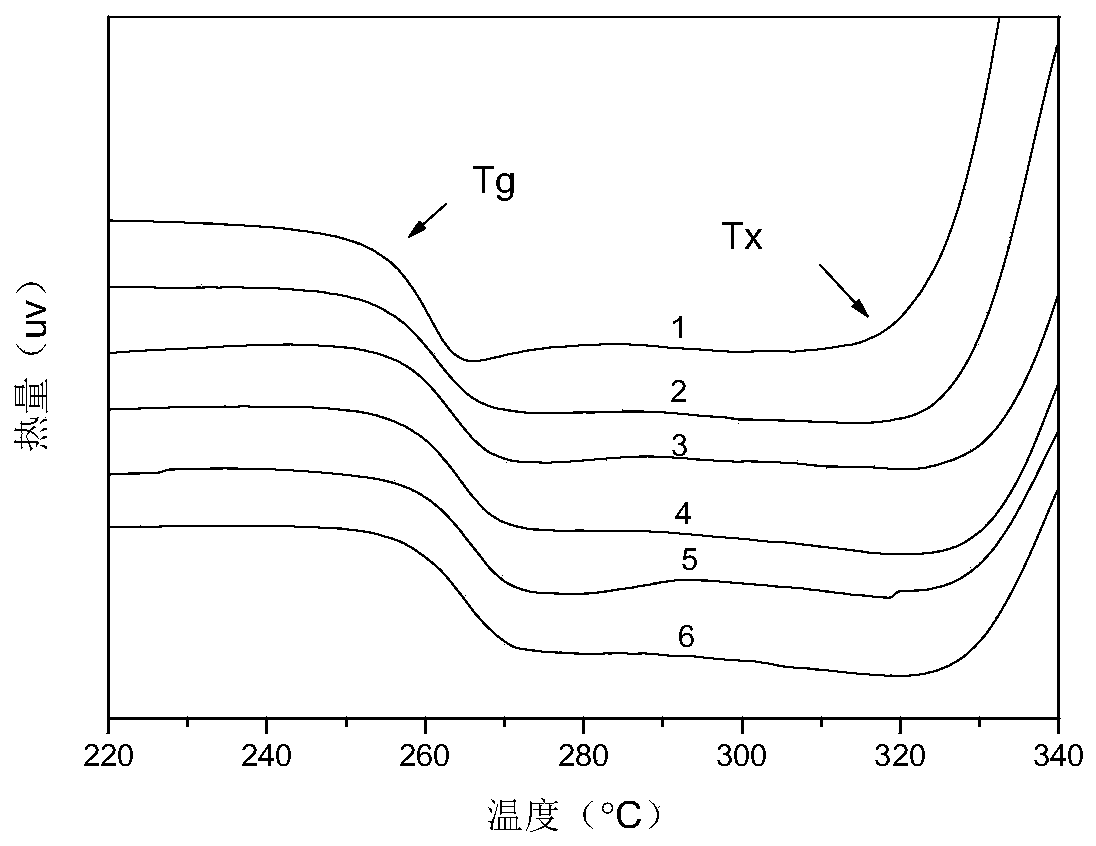

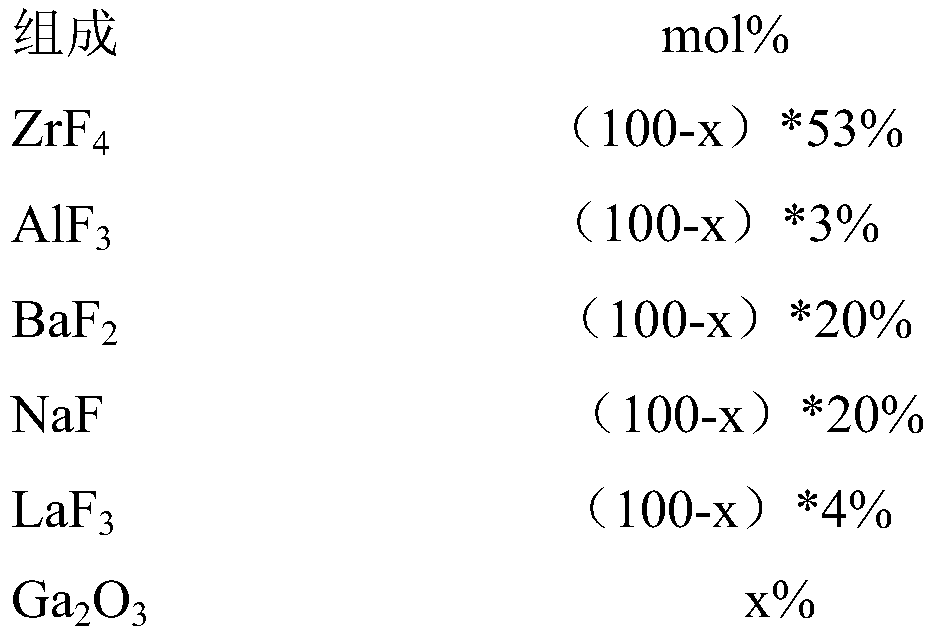

[0028] Calculate the weight percent of the glass according to x=0.5 mole percent (mol%) of the glass composition, and the preparation process is basically the same as in Example 1. The prepared glass is colorless and transparent, and its thermal stability parameters are shown in the figure.

Embodiment 3

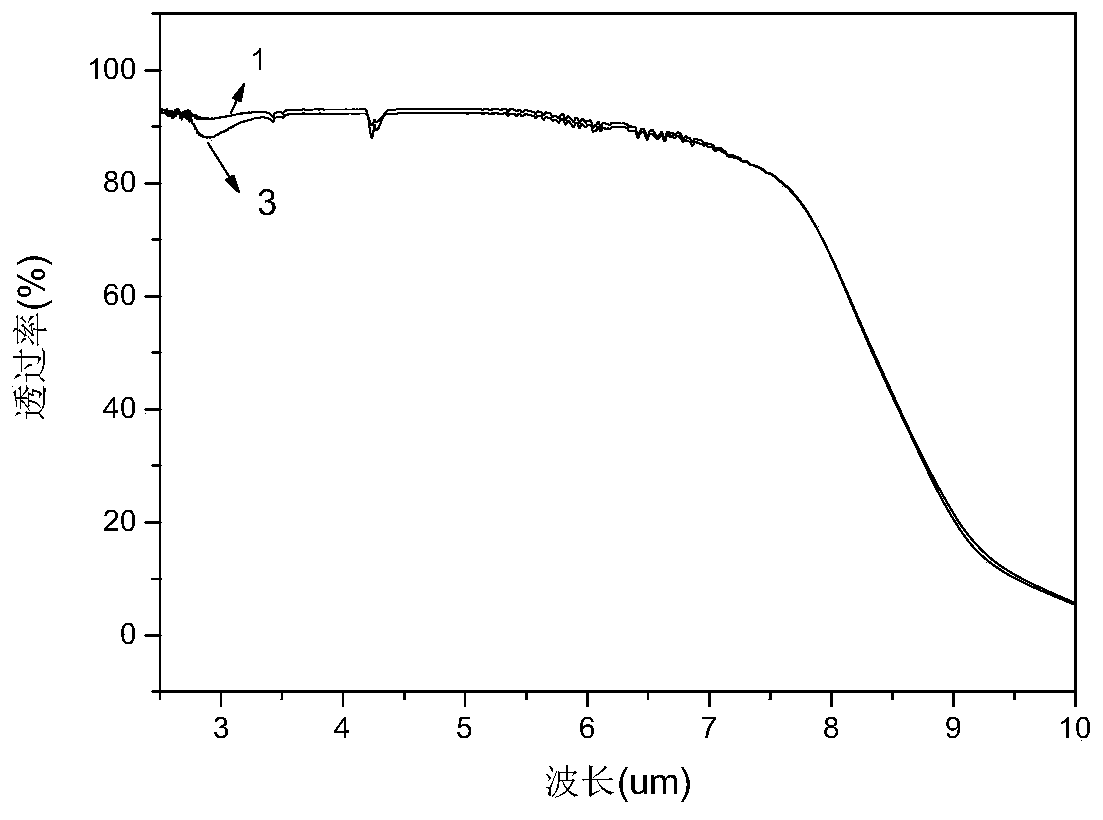

[0030] Calculate the weight percentage of glass according to x=1.0 glass composition mole percentage (mol%), then weigh each raw material, add auxiliary reagent NH in the proportion of 25% of the total mass of raw materials 4 HF 2 , mix evenly; then put the uniform powder mixture into a platinum crucible, cover it with a platinum lid, put it into a silicon carbide rod electric furnace at 860°C, melt it for 1 hour, and clarify it for 45 minutes; cool down to 700-800°C, and pour the glass liquid In a preheated stainless steel mold; then quickly move the glass into a muffle furnace that has been heated to the transition temperature (Tg), keep it warm for 4 hours, and then anneal it to room temperature at a speed of 10°C / min. The obtained glass is colorless and transparent , the prepared glass is colorless and transparent, and the thermal stability parameters and infrared transmission spectrum are shown in the figure.

Embodiment 4

[0032] Calculate the weight percent of the glass according to x=1.5 glass composition mole percent (mol%), and the preparation process is basically the same as that of Example 3. The prepared glass is colorless and transparent, and its thermal stability parameters are shown in the figure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com