PEEK powder with high processing property and preparation method and application thereof

A processing performance and powder technology, which is applied in the field of PEEK powder and its preparation, can solve the problems of unstable parts performance, inability to sinter, and low bulk density, and achieve the effects of improving processing stability, avoiding insufficient transportation, and high bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

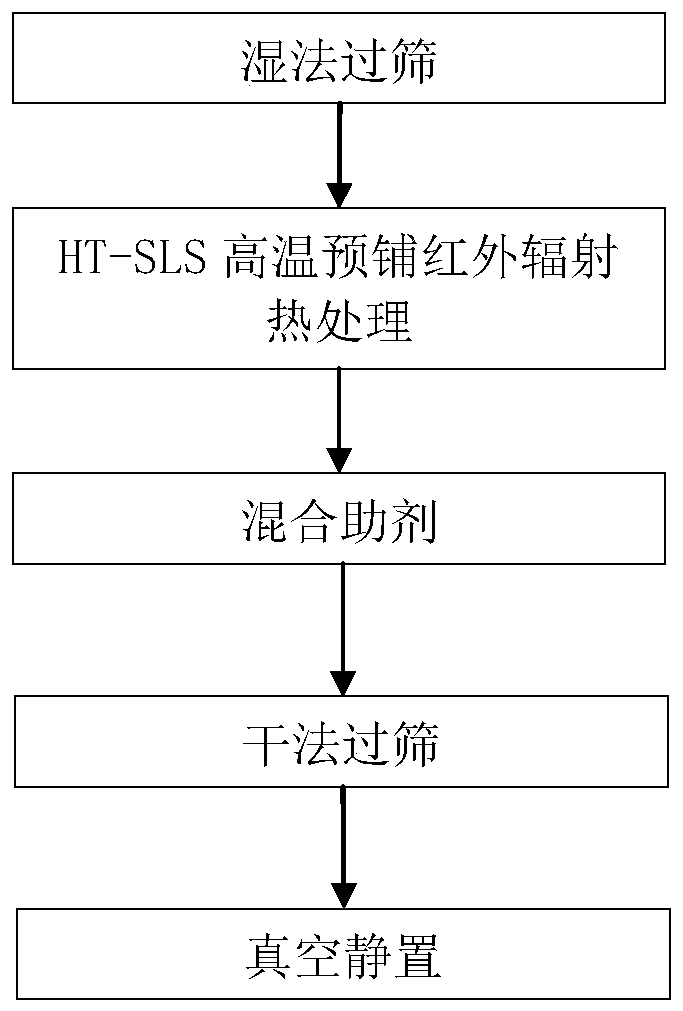

[0031] Such as figure 1 As shown, the preparation method of a PEEK powder with high processability provided by the embodiment of the present invention includes the following steps.

[0032] (1) wet sieving

[0033] Add the existing PEEK powder into the alcohol aqueous solution, and manually stir it in a suspended state to obtain a suspension, wherein, in the alcohol aqueous solution, the volume ratio of the alcohol solution to water is 2:8 to 9:1; preferably, alcohol and water The volume ratio is 1:1. Preferably, the alcohol solution is an ethanol solution.

[0034] The suspension is passed through a high-mesh sieve, and at the same time, it is necessary to continuously transport the alcohol aqueous solution to the high-mesh sieve to ensure that the small particle PEEK powder in the suspension can pass through the high-mesh sieve smoothly. When the filtrate passing through the high-mesh sieve no longer has small white particles of PEEK powder, stop the filtration operation....

Embodiment 1

[0049] Configure an alcohol aqueous solution with a volume ratio of 5:5, add the existing PEEK powder into the alcohol aqueous solution, and manually stir it in a suspended state; pass the suspension through a 600-mesh sieve, and at the same time, the alcohol aqueous solution is continuously transported to sieve out the small powder particles. Stop the operation when the filtrate does not appear white matter; collect the viscous matter on the sieve and filter it with suction, and the obtained solid block is initially crushed, put it in a vacuum oven for 48 hours at 150°C, and vacuum dry at a gauge pressure of 0.08Mpa to obtain the product Grind and pass through a 100-mesh sieve to obtain the first PEEK powder.

[0050] Put the first PEEK powder into the powder feeding tank of HT-SLS equipment; set the pre-spreading parameters: pre-spreading start temperature 260°C, pre-spreading holding temperature 260°C, powder-spreading time interval 30s, single-layer thickness of powder-spra...

Embodiment 2

[0058] Configure an alcohol aqueous solution with a volume ratio of 2:8, add the existing PEEK powder to the alcohol aqueous solution, and manually stir it to be in a suspended state; pass the suspension through a 400-mesh sieve, and at the same time, the alcohol aqueous solution is continuously transported to sieve out the small powder particles; The viscous matter on the sieve was collected and suction filtered, the obtained solid block was initially crushed, put into a vacuum oven for drying at 100°C for 60 hours, and vacuum-dried at a gauge pressure of 0.07Mpa. The obtained product was ground and passed through a 100-mesh sieve to obtain the first PEEK powder.

[0059] Put the first PEEK powder into the powder delivery tank of HT-SLS equipment; set the pre-spreading powder parameters: the pre-spreading start temperature is 170°C, the pre-spreading maintenance temperature is 170°C, the powder-spreading time interval is 20s, the single-layer thickness of the powder-spreading l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com