Nanofiber-xanthan gum composite viscosity-increasing and cutting agent for drilling fluid and preparation method

A technology of viscosity raising and cutting agent and nanofiber, which is applied in the field of oil drilling, can solve the problems of weak temperature resistance and poor cutting effect, and achieve the effect of improving temperature resistance, good temperature resistance and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

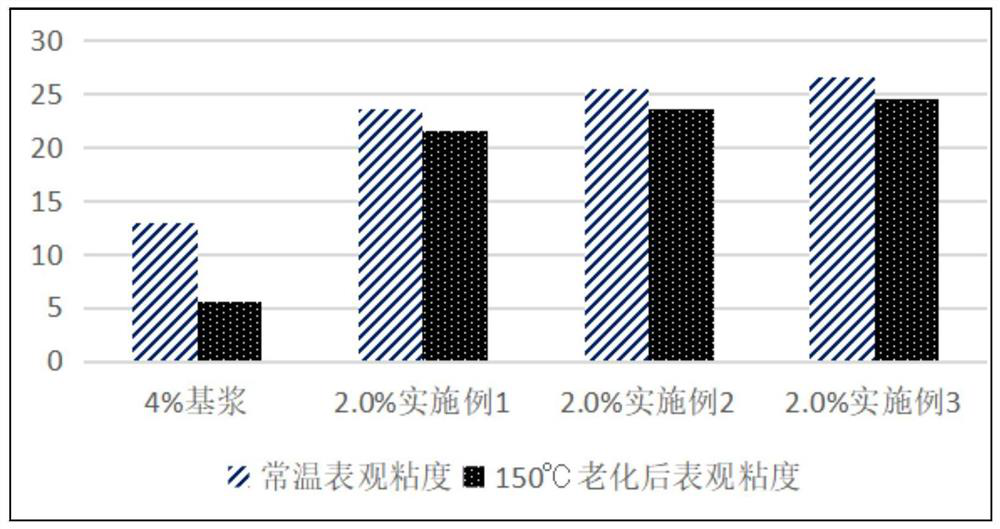

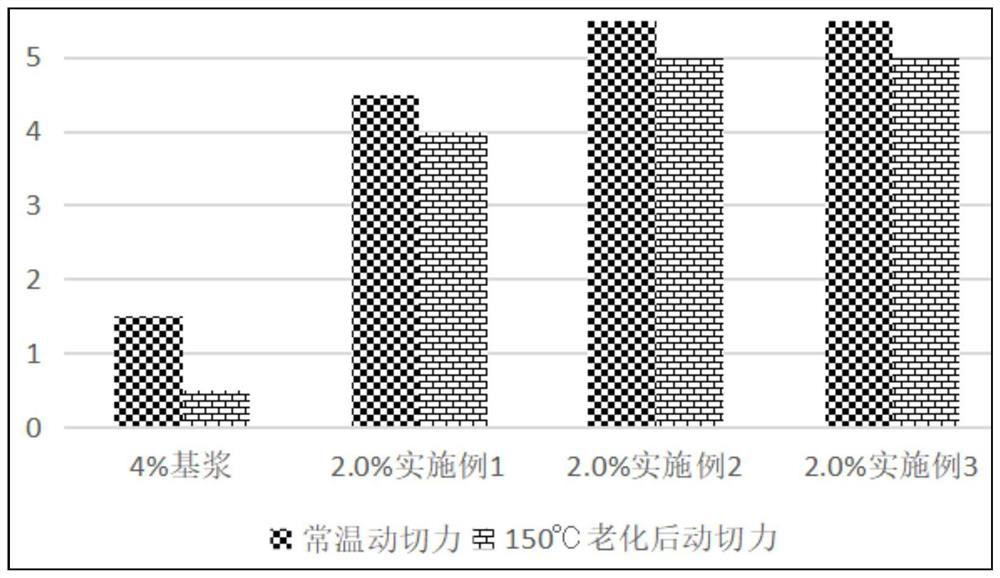

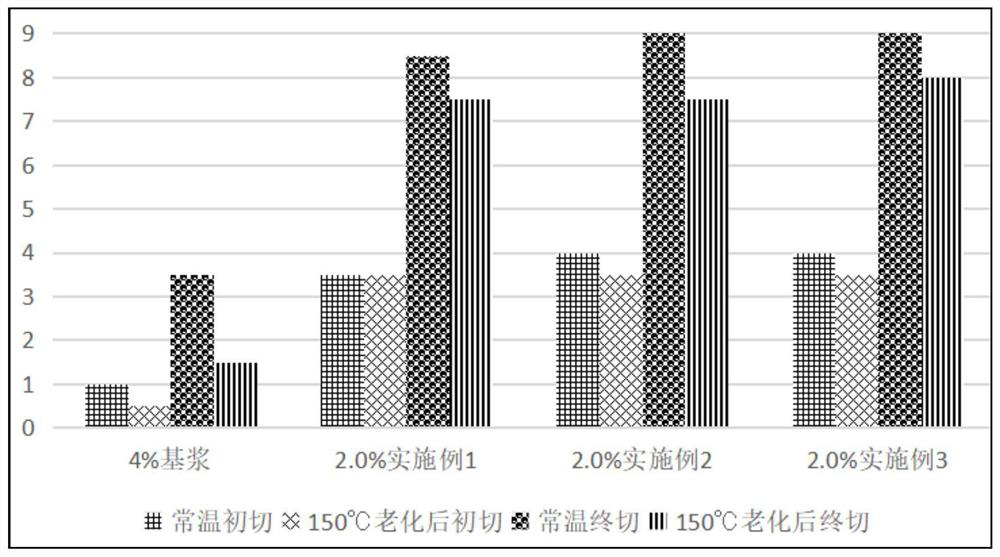

Embodiment 1

[0035] Pour 300g of 98% sulfuric acid into a 1000mL beaker, slowly add deionized water dropwise, while stirring gently with a glass rod, until the sulfuric acid is diluted to 64wt%; add 120g of pretreated bagasse Slowly add 64wt% sulfuric acid to a 2000mL three-necked flat-bottomed flask, and stir at a low speed of 100rpm for 40min. React under the conditions for 3h, then add 6mL of ethylene glycol, stir at 1000rpm, continue to react for 1h, remove unreacted sodium periodate; increase the temperature of the reactor to 60°C, add 30g of trimethylacetyl chloride, and adjust the pH to 5.0, continue to react for 4h; add 20g cetyltrimethylammonium bromide, continue to react for 1h; transfer the above dispersion system into a 2000mL plastic cup, add excess deionized water to terminate the reaction; divide the above dispersion system Batch transfer to a centrifuge, centrifuge at 10,000rpm for 20 minutes, settle, pour out the supernatant, add deionized water, and centrifuge again at hi...

Embodiment 2

[0037] Pour 350g of 98% sulfuric acid into a 1000mL beaker, slowly add deionized water dropwise, while stirring gently with a glass rod, until the sulfuric acid is diluted to 64wt%; add 150g of pretreated bagasse Slowly add 64wt% sulfuric acid to a 2000mL three-necked flat-bottomed flask, and stir at a low speed of 100rpm for 50min. React under the conditions for 4h, then add 6mL of ethylene glycol, stir at 1000rpm, continue to react for 1.5h, remove unreacted sodium periodate; increase the temperature of the reactor to 60°C, add 40g of trimethylacetyl chloride, adjust the pH to 5.0, continue to react for 4h; add 25g of dodecyltrimethylammonium bromide, continue to react for 1.5h; transfer the above dispersion system into a 2000mL plastic cup, add excess deionized water to terminate the reaction; Transfer the system to a centrifuge in batches, centrifuge at 10,000rpm for 20min, settle, pour out the supernatant, add deionized water, and centrifuge again at high speed until the ...

Embodiment 3

[0039] Pour 400g of 98% sulfuric acid into a 1000mL beaker, slowly add deionized water dropwise, while stirring gently with a glass rod, until the sulfuric acid is diluted to 64wt%; add 160g of pretreated bagasse Slowly add 64wt% sulfuric acid to a 2000mL three-necked flat-bottomed flask, and stir at a low speed of 100rpm for 60min. Under the conditions of reaction for 5h, then add 6mL of ethylene glycol, stirring speed 1000rpm, continue to react for 2h, remove unreacted sodium periodate; increase the temperature of the reactor to 60°C, add 50g of trimethylacetyl chloride, adjust the pH to 5.0, continue to react for 4h; add 30g of dodecyltrimethylammonium chloride, continue to react for 2h; transfer the above dispersion system to a 2000mL plastic cup, add excess deionized water to terminate the reaction; divide the above dispersion system Batch transfer to a centrifuge, centrifuge at 10,000rpm for 20 minutes, settle, pour out the supernatant, add deionized water, and centrifug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com