Coated proppant used for unconventional reservoir hydraulic fracturing as well as preparation and application of coated proppant

A technology for hydraulic fracturing and proppant, which is applied in drilling compositions, chemical instruments and methods, and production fluids, etc., can solve the problems of low-density corrosion resistance, high cost, interface damage, etc., and achieve enhanced connection and flowback. The effect of low rate and strong suspension ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

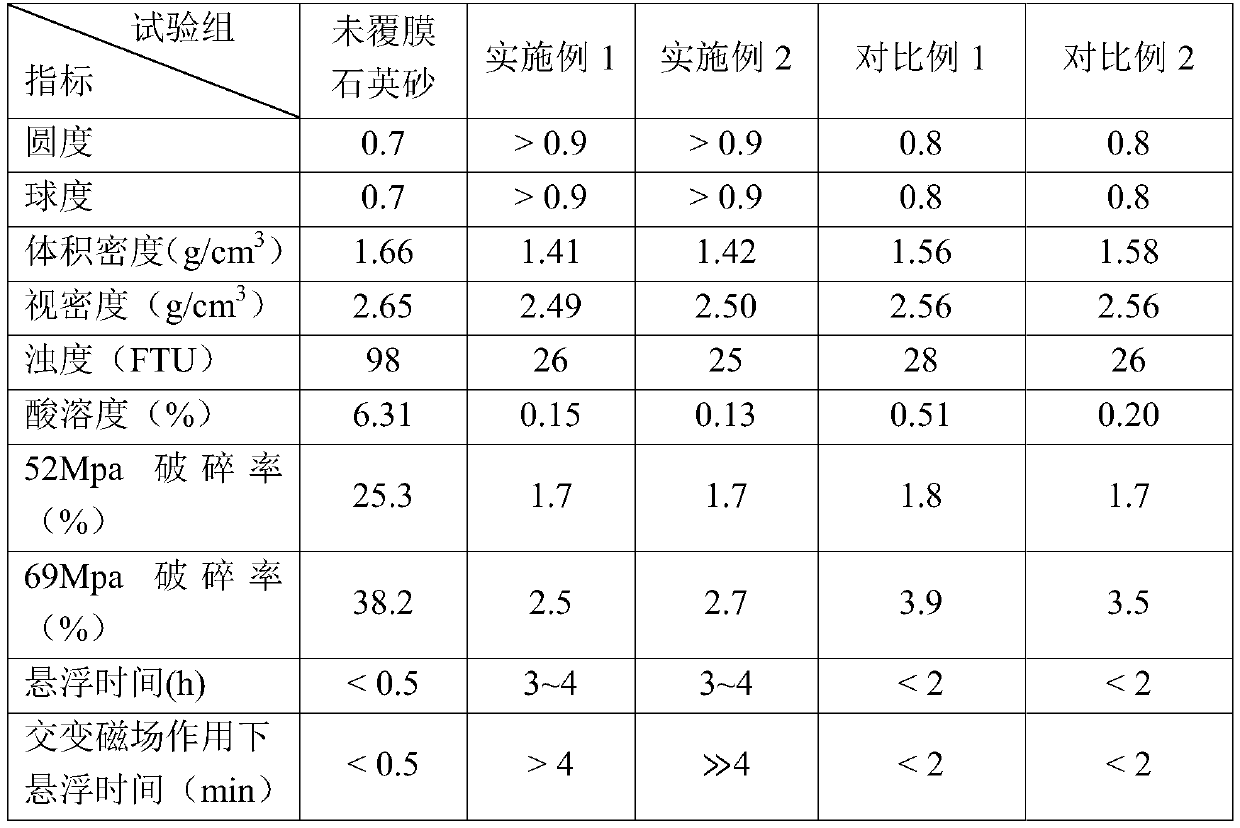

Embodiment 1

[0095] (1) Prepare the following materials: 100 parts of aggregate, 3 parts of polyurethane, 2 parts of polyol resin (polyester polyol polyurethane with a hydroxyl equivalent of 50-100), curing agent dibenzoyl peroxide (Foshan Shengyi Bio Technology Co., Ltd.) 1 part, catalyst 0.003 part, carbon quantum dot fluorescent particles 0.3 part, two-dimensional transition metal carbide 0.1 part, graphene 0.1 part, amine additive (ethylene diamine) 0.15 part.

[0096] (2) Heat the aggregate in step (1) to about 250°C, and pour it into a casserole mixing pot for sand mixing.

[0097] (3) Add the polyurethane in step (1) to the casserole mixing pot, and when the temperature drops below 210°C, add the curing agent for coating.

[0098] (4) Mix the polyol resin, carbon quantum dot fluorescent particles, two-dimensional transition metal carbide, and graphene uniformly, and heat to about 150°C for use.

[0099] (5) When the temperature of the mixing casserole drops to 80-150°C, the mixture in step ...

Embodiment 2

[0102] (1) Prepare the following materials: 100 parts of aggregate, 5 parts of epoxy resin e44 (Jiangyin Wanqian Chemical Co., Ltd.), 1 part of curing agent dibenzoyl peroxide (Foshan Shengyi Biotechnology Co., Ltd.), magnetic graphite 0.2 parts of olefin, 0.3 parts of polystyrene microspheres, 0.003 parts of catalyst, and 2.5 parts of surface modifier.

[0103] (2) Heat the aggregate in step (1) to about 250°C, and pour it into a casserole mixing pot for sand mixing.

[0104] (3) Add the epoxy resin in step (1) to the mixing casserole, and when the temperature drops below 210°C, add the curing agent to cover the film.

[0105] (4) When the temperature drops to 150°C, spray the surface modifier with water into the mixing casserole.

[0106] (5) When the temperature of the mixing casserole drops to 120°C, add the ultrapure aqueous solution of magnetic graphene and the ultrapure aqueous solution of polystyrene microspheres into the mixing casserole with hot air blowing, and the speed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com