All-inorganic perovskite layer and preparation method and application thereof

An inorganic calcium and perovskite technology, applied in the field of solar cells, can solve the problems of poor stability of perovskite cells, unstable perovskite phase, and easy decomposition of organic components, so as to inhibit the migration of ions, maintain stability, and improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also discloses a method for preparing an all-inorganic perovskite layer doped with a stabilizer as described above, comprising the following steps:

[0042] 1) Prepare an all-inorganic perovskite precursor solution;

[0043] 2) adding a stabilizer to the all-inorganic perovskite precursor solution to obtain a precursor stabilizer mixed solution;

[0044] 3) Prepare the all-inorganic perovskite layer by any one of the processing methods of spin coating, scraping coating, or spraying the mixed solution of the precursor stabilizer.

[0045] Wherein, the concentration of the stabilizer is 5mg / mL-12mg / mL, within this range, the stabilizer can better inhibit the migration of halide ions, stabilize the perovskite phase, and improve the stability of the perovskite battery.

[0046] In the process of spin coating, scraping coating or spraying the precursor stabilizer mixed solution, an anti-solvent extraction step can also be carried out to improve the fil...

Embodiment 1

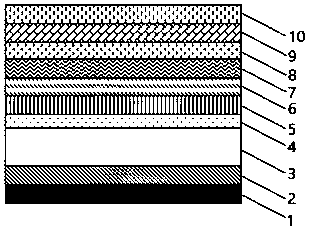

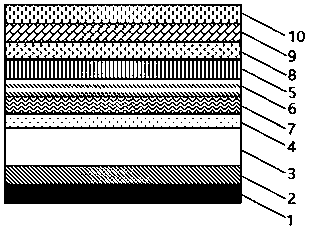

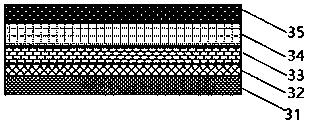

[0065] Such as figure 1 The structural diagram of the perovskite / silicon heterojunction solar tandem cell shown, including the first back electrode layer, the first transparent conductive layer, the silicon heterojunction layer, the tunneling layer, the electron transport layer, the calcium Titanium ore layer, hole transport layer, inorganic protective layer, second transparent conductive layer, second back electrode layer; the structure of the silicon heterojunction layer is as follows image 3 As shown, it includes an N-type amorphous silicon layer, a first intrinsic amorphous silicon layer, an N-type monocrystalline silicon layer, a second intrinsic amorphous silicon layer, and a P-type amorphous silicon layer arranged in sequence; perovskite / The specific preparation steps of the silicon heterojunction solar tandem cell are as follows:

[0066] 1) Prepare an N-type single crystal silicon layer: place the N-type single crystal silicon substrate in a KOH solution for etchin...

Embodiment 2

[0080] As in Example 1, the difference is that the concentration of phenyltrimethylammonium chloride in step 8) is 8 mg / mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com