Crushing machine

A crusher and crushing roller technology, applied in grain processing and other directions, can solve problems such as affecting crushing efficiency, affecting crushing quality, and fragile crushing teeth, and achieves the effect of uniform product particle size, wide application range and small external size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

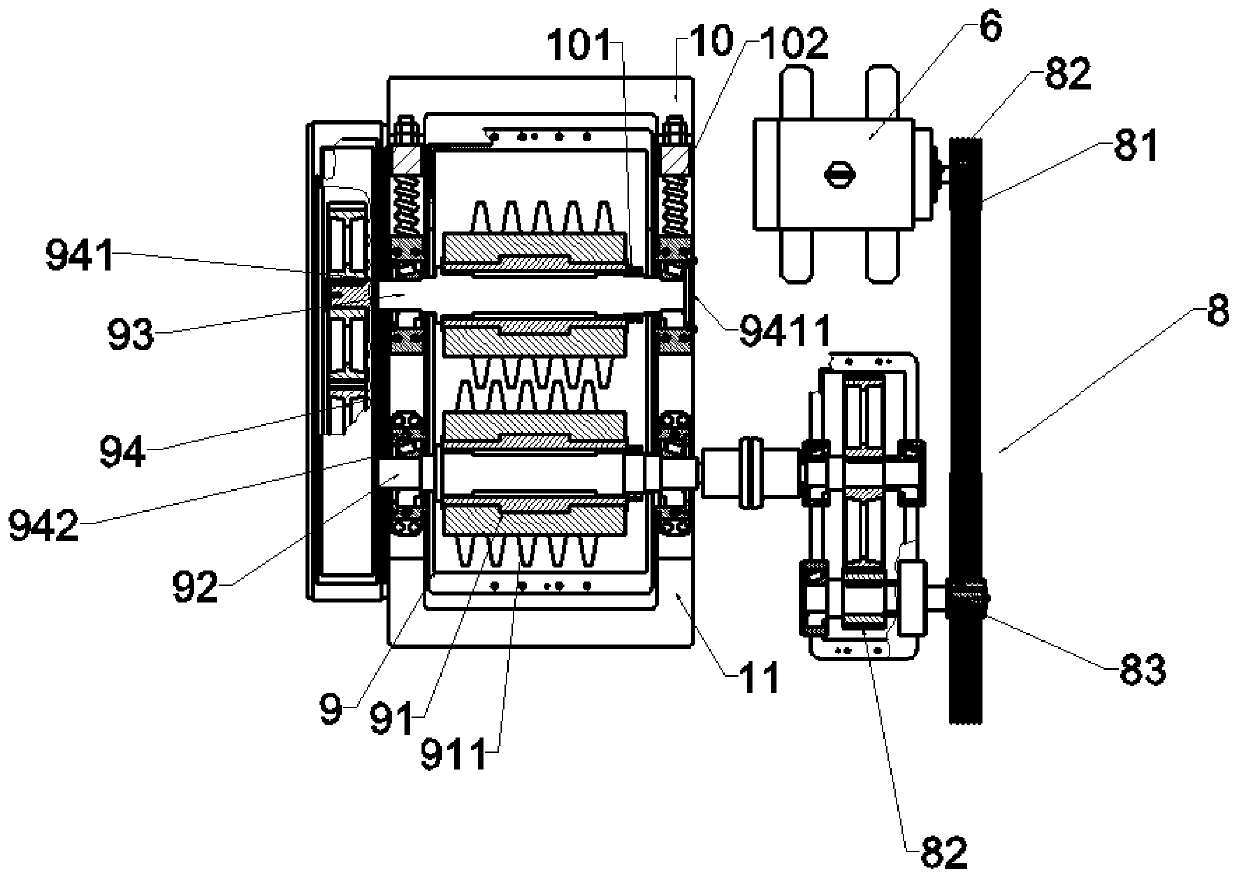

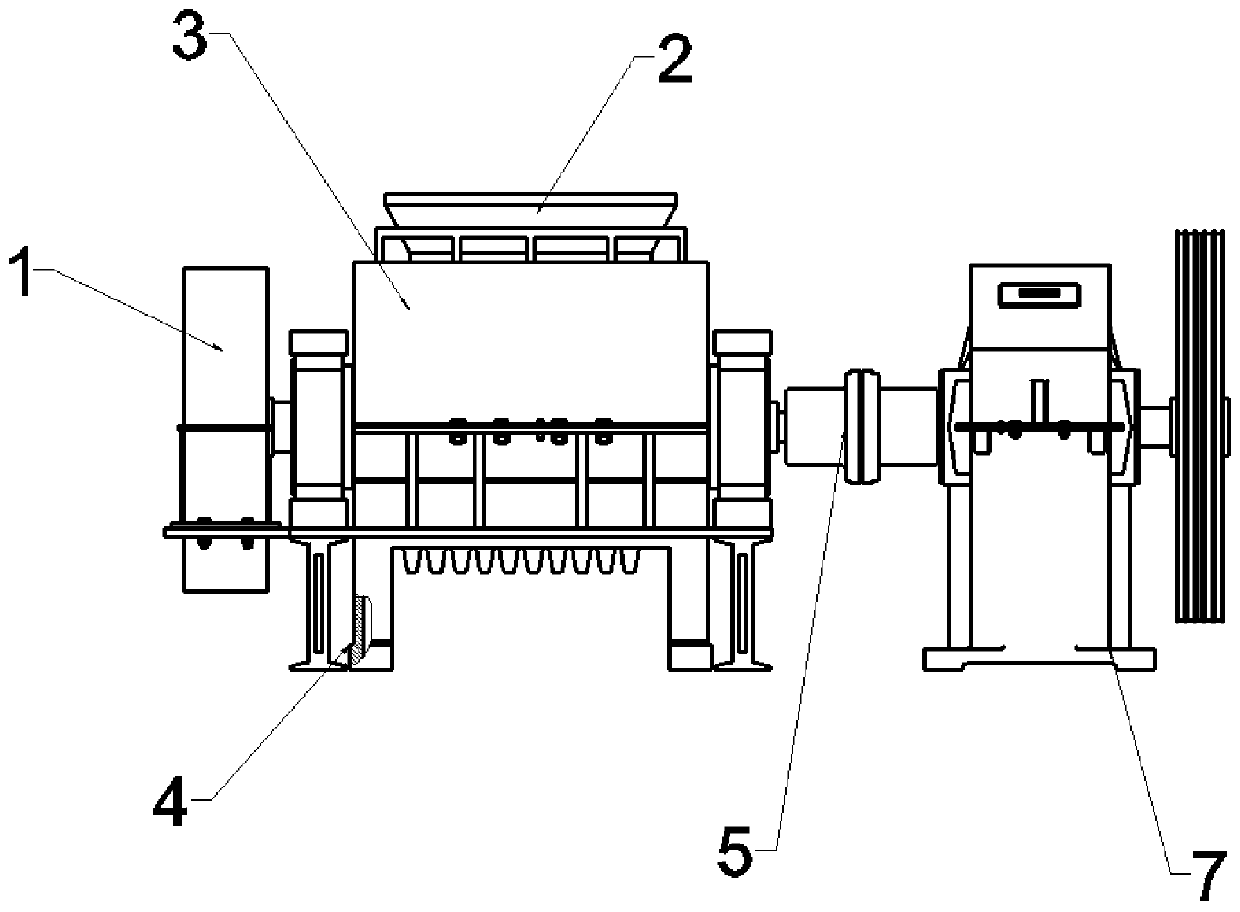

[0032] A crusher includes a transmission gear 1, a feed hopper 2, a box body 3, a bearing frame 11, a frame 4, a coupling 5, a reducer bracket 7, and a power device 6. It is characterized in that it also includes a crushing device 9. The deceleration system 8 and the gap control device 10, the crushing device 9 can realize distance regulation through the gap control device 10, the deceleration system 8 is a two-stage deceleration; the crushing device includes a crushing roller 91, a crushing roller The driving shaft 92, the crushing roller driven shaft 93 and the bearing housing 94, the crushing roller driving shaft 92 can drive the crushing roller driven shaft 93; the crushing rollers passing through the crushing roller driving shaft 92 to form a series connection are called fixed crushing rollers The crushing rollers formed in series through the crushing roller driven shaft 93 are called mobile crushing rollers, and the fixed crushing roller and the mobile crushing roller are...

Embodiment 2

[0034] A crusher includes a transmission gear 1, a feed hopper 2, a box body 3, a bearing frame 11, a frame 4, a coupling 5, a reducer bracket 7, and a power device 6. It is characterized in that it also includes a crushing device 9. A deceleration system 8 and a gap regulating device 10, the crushing device 9 can realize distance regulation through the gap regulating device 10, and the decelerating system 8 is a two-stage deceleration.

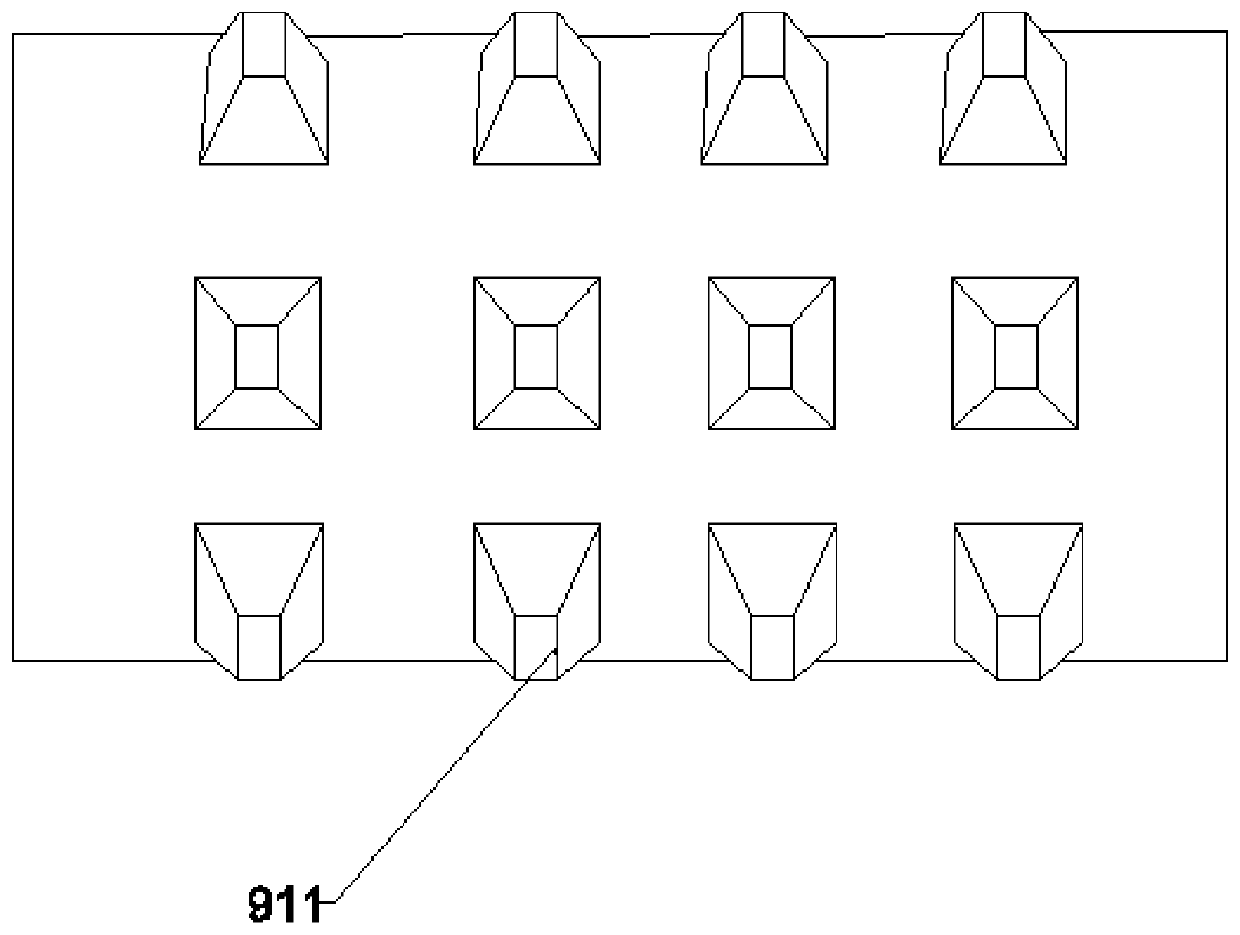

[0035] The crushing device includes a crushing roller 91, a crushing roller driving shaft 92, a crushing roller driven shaft 93 and a bearing seat 94, and the crushing roller driving shaft 92 can drive the crushing roller driven shaft 93; A plurality of pyramidal teeth 911 are set, and the height of the rectangular pyramidal teeth is 60mm, so that the crushing force produced is relatively uniform, the phenomenon of over-crushing is significantly reduced, and the crushing efficiency is significantly improved; the front part of the pyramidal tee...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap