Modified PA6/PA12 alloy material with low water absorption and preparation method thereof

A low water absorption, alloy material technology, applied in the field of polymer material processing, can solve the problems of water absorption and dimensional stability research without PA6/PA12 materials, and achieve the effects of shortening crystallization time, improving physical properties, and increasing crystallization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

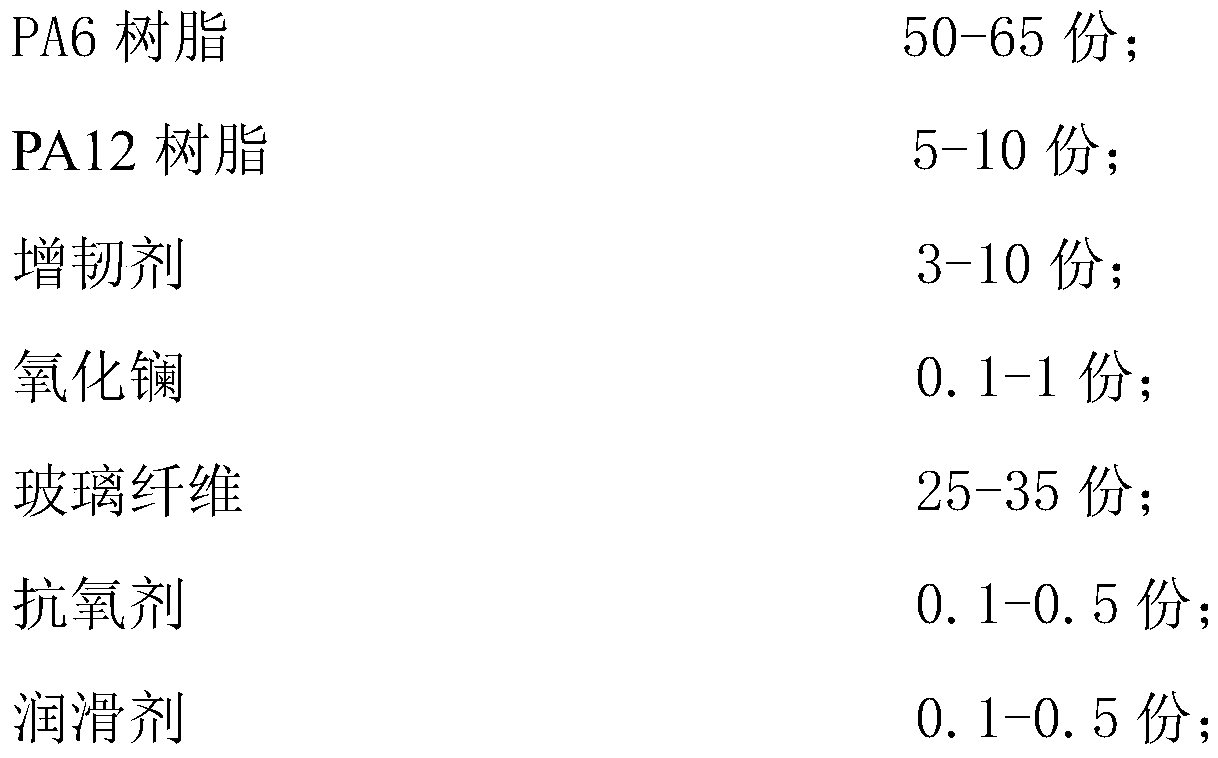

[0024] A modified PA6 / PA12 alloy material with low water absorption, comprising the following components in parts by weight:

[0025]

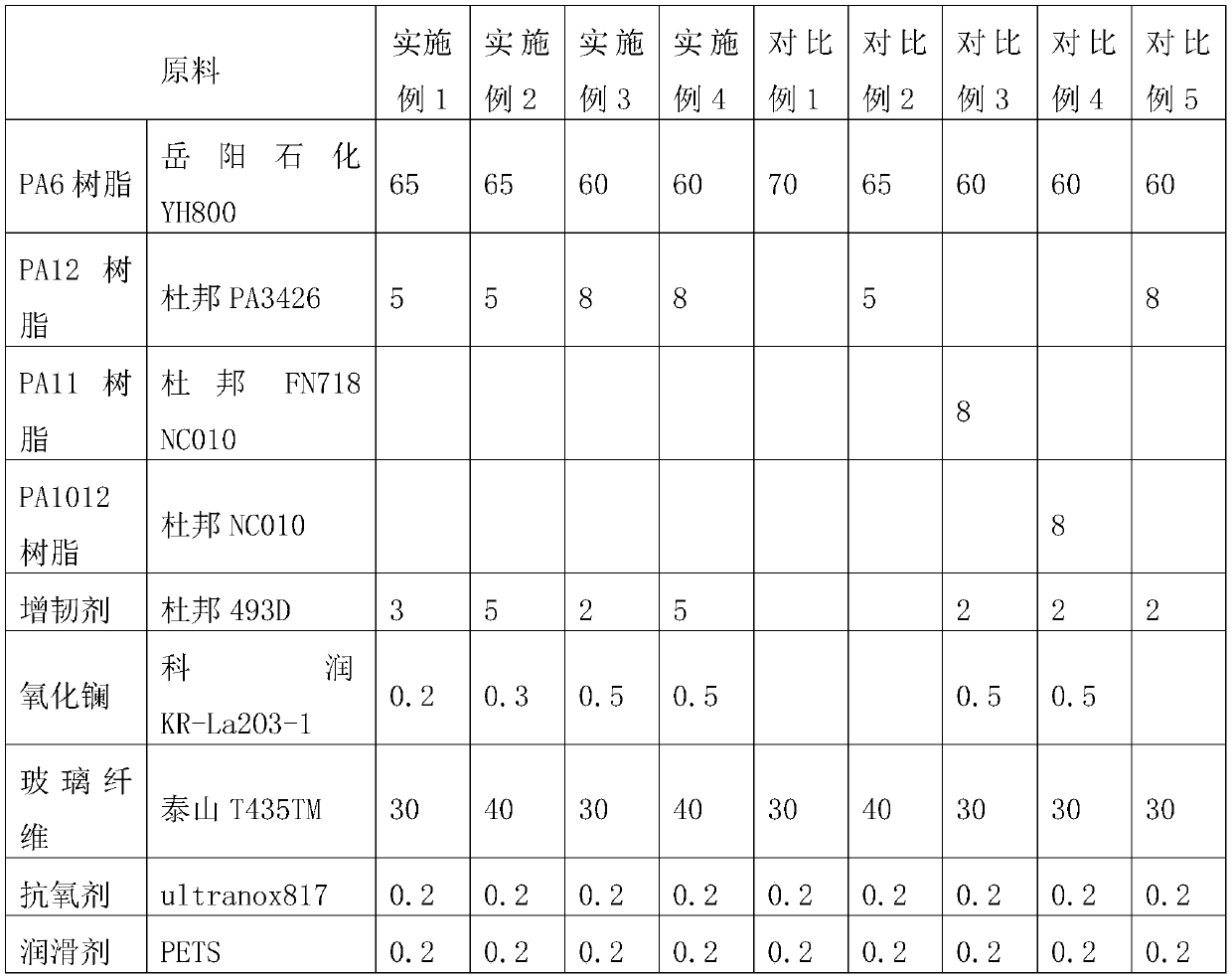

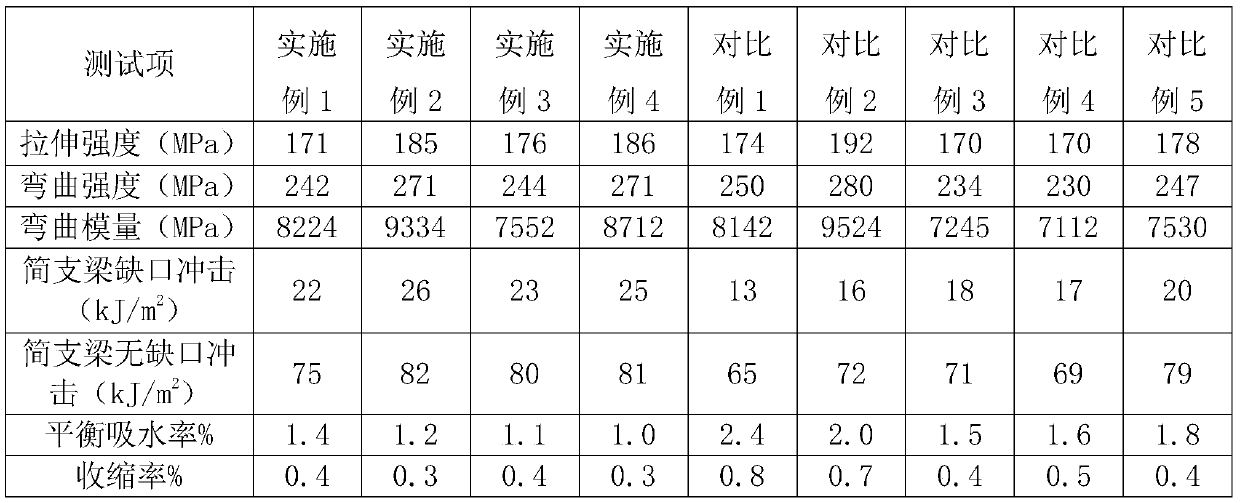

[0026] Prepare the material of embodiment 1-4 and comparative example 1-5 by following preparation method:

[0027] (1) Add PA6 and PA12 resins to a high-speed mixer, then add toughening agent, lanthanum oxide, antioxidant, lubricant, and then stir evenly in a high-speed mixer at room temperature (see Table 1 for the specific materials added) , the PA12 resin is an amorphous polyamide resin with a crystallinity between 55-65%);

[0028] (2) Put the mixed material in a co-rotating twin-screw extruder, add glass fiber in the form of side feeding in the extrusion process, and melt and plasticize, extrude, cool, and pelletize to obtain polypropylene Composite materials; the twin-screw extruder used, the screw diameter is 40-65mm, the length-to-diameter ratio of the screw is 40:1, the mixing and melting temperature is set at 220°C-240°C for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com