Artificial borehole wall for preventing mudstone formation mud from being produced or channeling, forming method and well-completion structure

A technology of artificial well walls and rock formations, which is applied in wellbore/well components, drilling equipment, earthwork drilling and production, etc. It can solve the problems of reducing oil well productivity, time-consuming and laborious, and shortening the length of oil and gas production sections, so as to save working hours and costs , The construction process is simple, the production effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

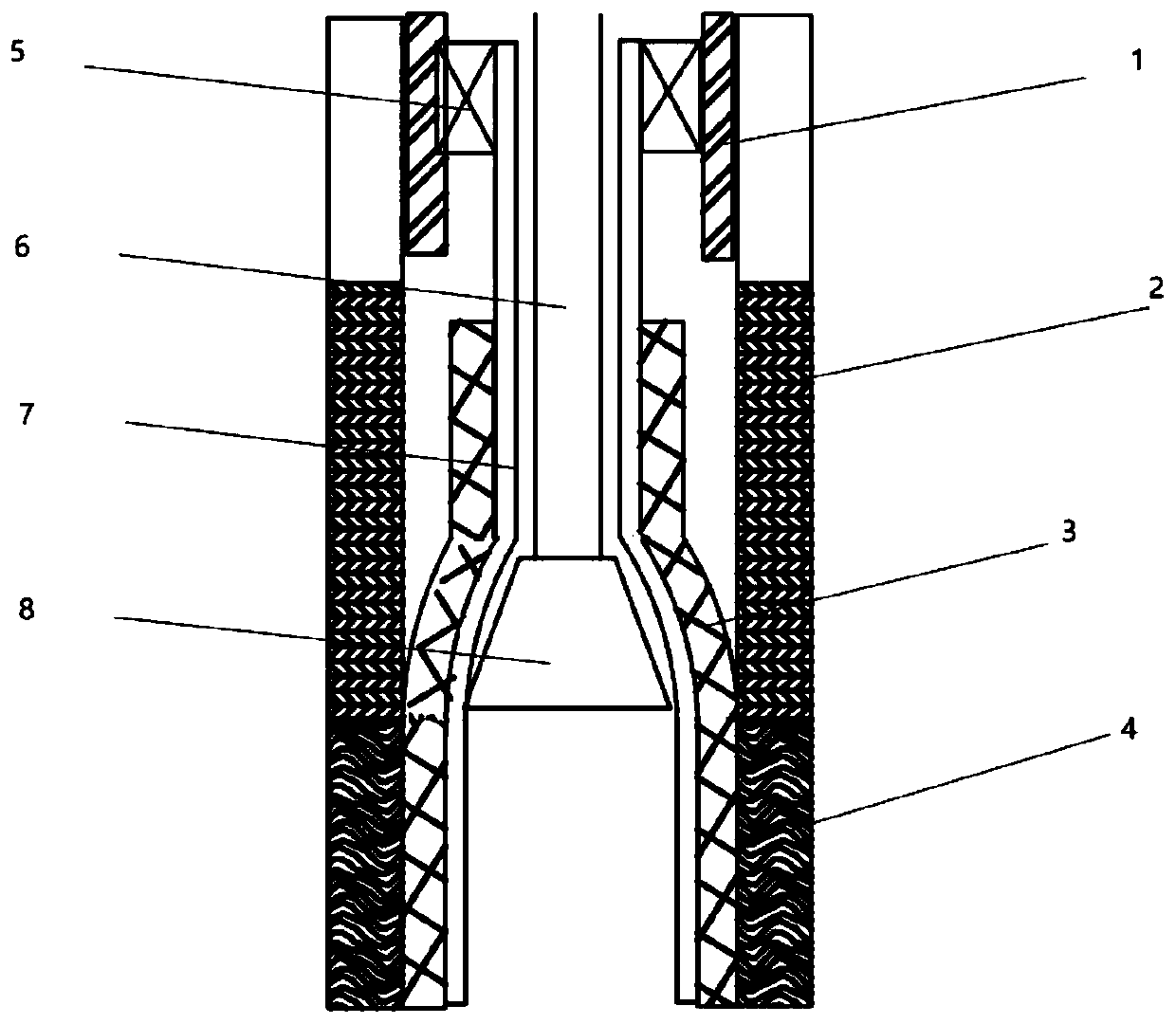

[0040] This embodiment provides a specific implementation method of using a physical expansion pipe to construct a porous medium artificial well wall that prevents the output or channeling of mudstone layer mud, including the following steps:

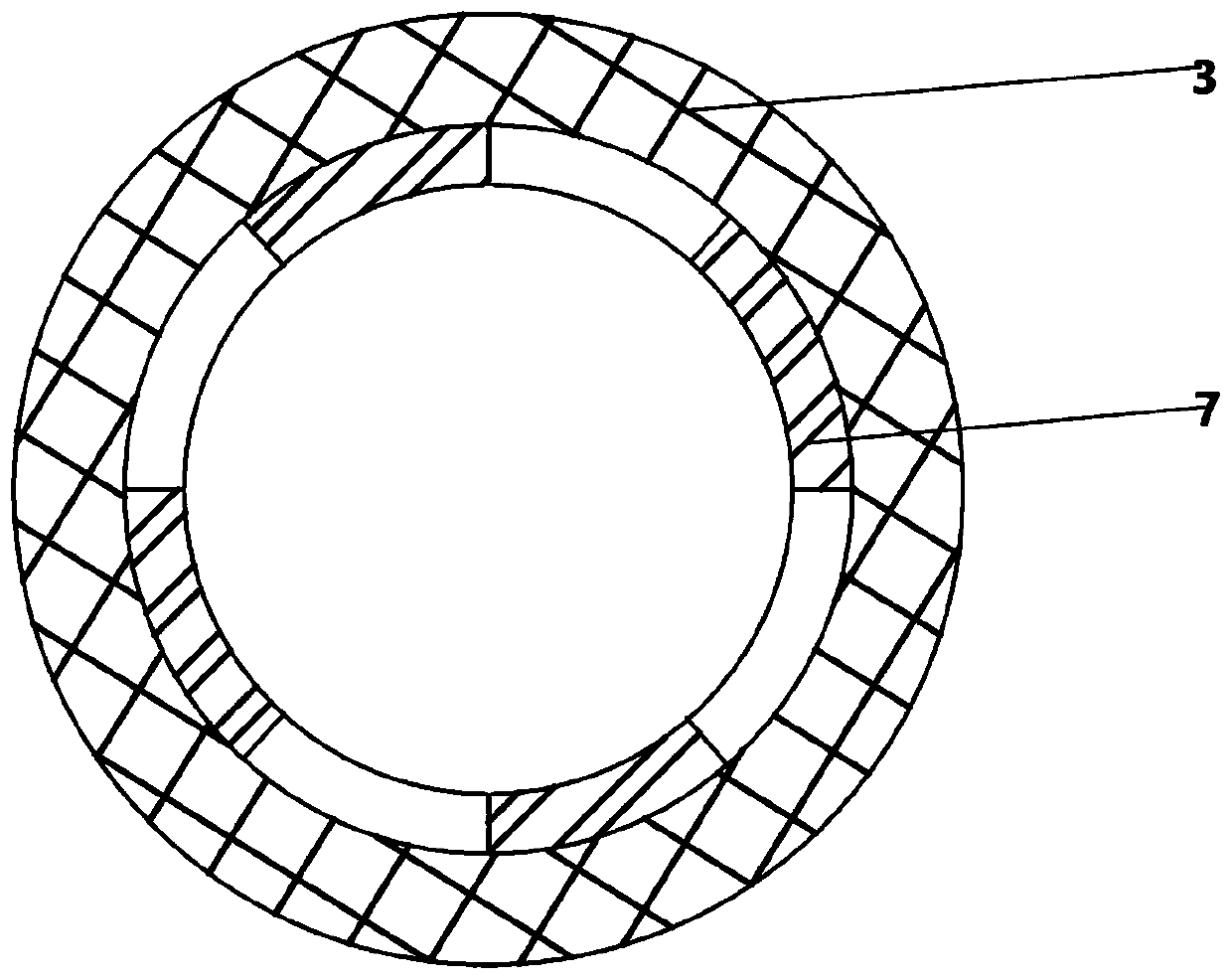

[0041] (1) Lower the expansion pipe whose outer layer is wrapped with a porous medium material layer into the wellbore. Specifically, the expansion tube is a cylindrical structure made of metal or alloy, and can expand outward along its radial direction. As a specific embodiment of the expansion tube, a structure similar to that of a heart stent can be used, for example, axial grooves are carved on the tube wall, and the structure can be expanded into a rhomboid network structure.

[0042] (2) After the expansion pipe is lowered to the specified position, use the mechanical force generated during the process of lifting the central pipe string (with expansion cone), or use the internal stress of the expansion pipe in the compressed state...

Embodiment 2

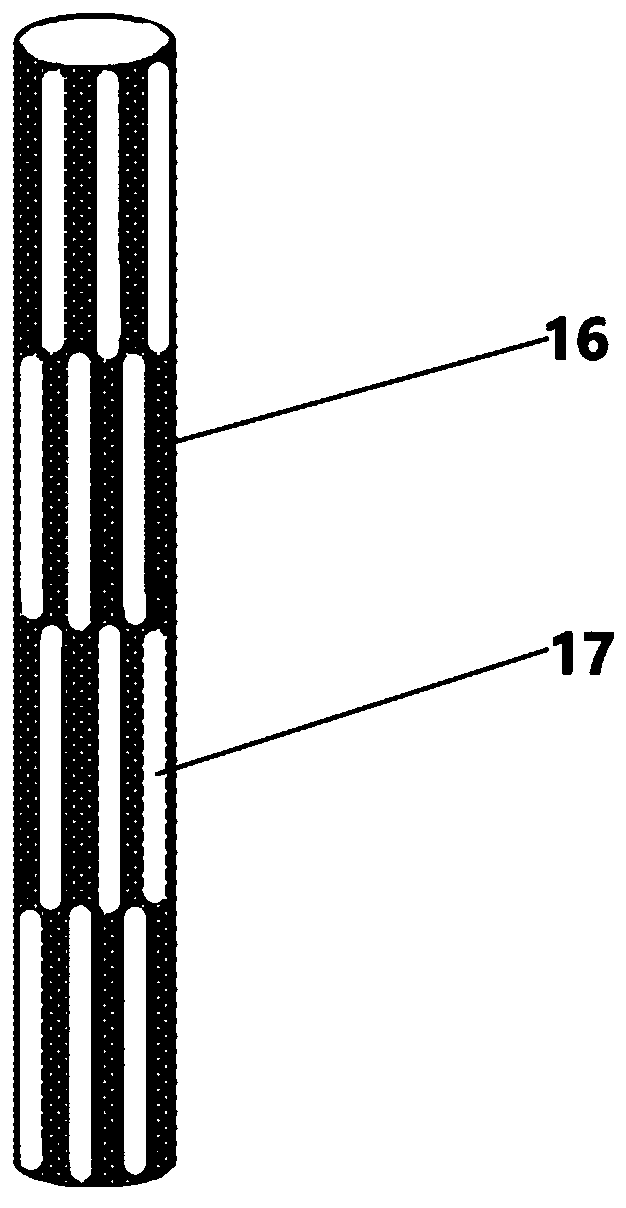

[0048] This embodiment provides a specific implementation method of using a self-expanding porous medium pipe string to form a porous medium artificial well wall to prevent mudstone layer mud production or channeling, including the following steps:

[0049] (1) Lowering into the wellbore a central pipe string with a solid expanded porous material attached to its outer surface; specifically, the solid expanded material can be artificial or natural fiber cotton bonded and tightly compacted by a water-soluble adhesive, Or a sponge.

[0050] (2) After the central pipe string is driven into the designated position, under the immersion action of the fluid in the wellbore, the solid expanded material expands and becomes larger and clings to the wellbore wall, forming a porous medium artificial wellbore wall. Specifically, the water-soluble adhesive gradually melts under the immersion of the wellbore fluid, and the tightly compacted fiber cotton or sponge absorbs water and expands und...

Embodiment 3

[0055] This embodiment provides a specific implementation method of adopting chemical pouring method to form a porous medium artificial well wall to prevent mudstone layer mud from outputting or channeling, including the following steps:

[0056] (1) Run the central pipe string into the wellbore;

[0057] (2) Inject cement slurry mixed with a foaming agent into the annular space between the central pipe string and the wellbore well wall; specifically, the quantity of the foaming agent mixed in the cement slurry should be such that the cement after solidification Pores forming a microchannel structure are preferred.

[0058] (3) After the cement slurry or high molecular polymer mother liquid is solidified, a porous medium artificial well wall is formed.

[0059] (4) After being put into production, when the mud fluid flows through the micropores in the porous media material of the artificial well wall, mud plugging can occur in the micropores and form mud cakes, thereby preven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| True density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com