Lithium-lanthanum-zirconium oxide-based solid electrolyte material capable of inhibiting lithium dendrites, and preparation method and application thereof

A solid electrolyte, lithium lanthanum zirconium oxide technology, applied in the manufacture of electrolyte batteries, electrolytes, non-aqueous electrolyte batteries, etc., can solve the problems of LLZO and metal lithium wettability to be improved, battery short circuit, safety restrictions on lithium-ion batteries, etc. Achieve the effects of improving cycle stability, inhibiting growth, and preventing precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the lithium-lanthanum-zirconium-based solid electrolyte material capable of suppressing lithium dendrites comprises:

[0041] (1) preparing the lithium lanthanum zirconium oxide solid electrolyte;

[0042] The preparation method of the lithium-lanthanum-zirconium-based solid electrolyte is a sol-gel method, and the preparation steps include: the precursors of lithium Li, lanthanum La, zirconium Zr and the doping element M according to the molar ratio of Li, La, Zr, and M are (5+x): 3: x: (2-x) mixing, adding solvent to dissolve, adding precipitant to form sol-gel, heating and evaporating the solvent to obtain mixed powder; grinding the mixed powder, first at 250-600 sintering at 500-1000°C for 2-48 hours, grinding again, and then sintering at 500-1000°C for 2-48 hours to obtain the lithium-lanthanum-zirconium-based solid electrolyte.

[0043] Alternatively, the preparation method of the lithium-lanthanum-zirconium-based solid electrolyte is a ...

Embodiment 1

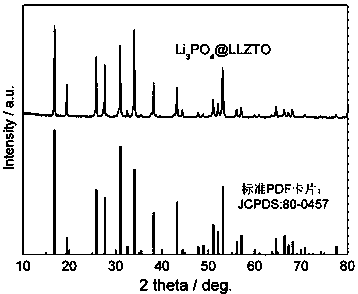

[0049] (1) The preparation of chemical formula is Li by solid phase reaction method 6.75 La 3 Zr 1.75 Ta 0.25 o 12 Lithium-lanthanum-zirconium-based solid electrolyte powder, the preparation steps of which include: selecting LiOH, La 2 o 3 , ZrO 2 and Ta 2 o 5 LiOH is used as a raw material, in which the excess of LiOH is 5wt%, and it is ball milled in alcohol for 24 hours and then dried; then it is calcined at 900°C for 10 hours, and the heating rate is 4°C / min. After the sintering is completed, the powder is crushed and sieved to obtain Li 6.75 La 3 Zr 1.75 Ta 0.25 o 12 Powder (LLZTO).

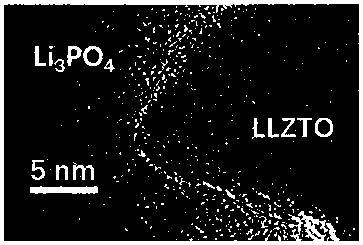

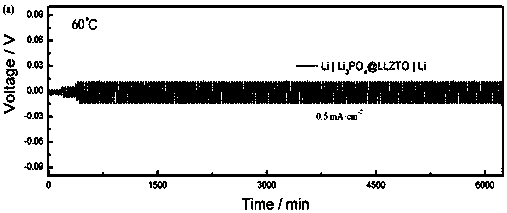

[0050] (2) Mechanical ball milling: the coating material Li 3 PO 4 The mixed material of the precursor and the LLZTO powder obtained in step (1) is placed in a grinding tank, ethanol is added, and the mixed material is ground with grinding balls; Separator separates the ball material to obtain mixed powder; the material of the grinding ball is zirconia, the ball-to-material ra...

Embodiment 2

[0057] It is basically the same as Example 1, the difference is that the cladding layer material is Li 2 ZrO 3 , to prepare Li 2 ZrO 3 Coating modified lithium lanthanum zirconium based solid electrolyte material (Li 2 ZrO 3 @LLZTO), where the cladding material Li 2 ZrO 3 The content is 2wt%.

[0058] Figure 5 Lithium lanthanum zirconium based solid electrolyte material (Li 2 ZrO 3 XRD spectrum of @LLZTO) by Figure 5 It can be seen that the lithium-lanthanum-zirconium-based solid electrolyte material (Li 2 ZrO 3 @LLZTO) still maintains a cubic phase with high ionic conductivity.

[0059] Figure 6 Lithium lanthanum zirconium based solid electrolyte material (Li 2 ZrO 3 TEM image of @LLZTO), courtesy of Figure 6 It can be seen that Li 2 ZrO 3 The nano-thin layer is uniformly coated on the surface of LLZTO.

[0060] Preparation of lithium lanthanum zirconium oxide ceramic sheets by hot pressing sintering method: Li 2 ZrO 3 @LLZTO powder is put into the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com