Reduced titanium oxide coating and preparation method and application thereof

A titanium oxide and coating technology, which is applied to reduced titanium oxide coatings, reduced titanium oxide coatings containing hydroxyl groups and trivalent titanium and their preparation fields, can solve the problem of reduced surface hydrophilicity and easy occurrence of Bacterial infection, weakened biological activity and other problems, to achieve the effect of promoting adhesion and proliferation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

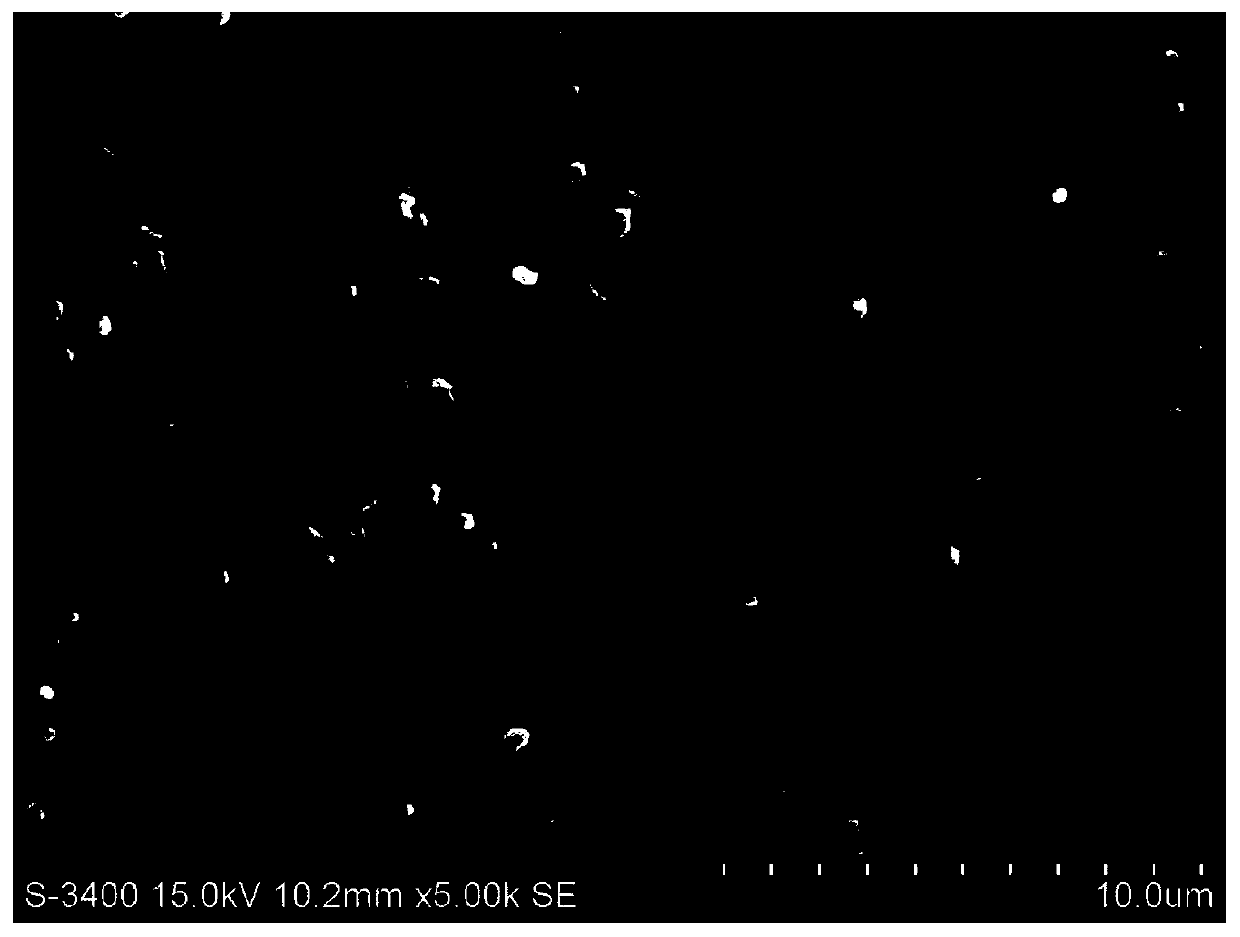

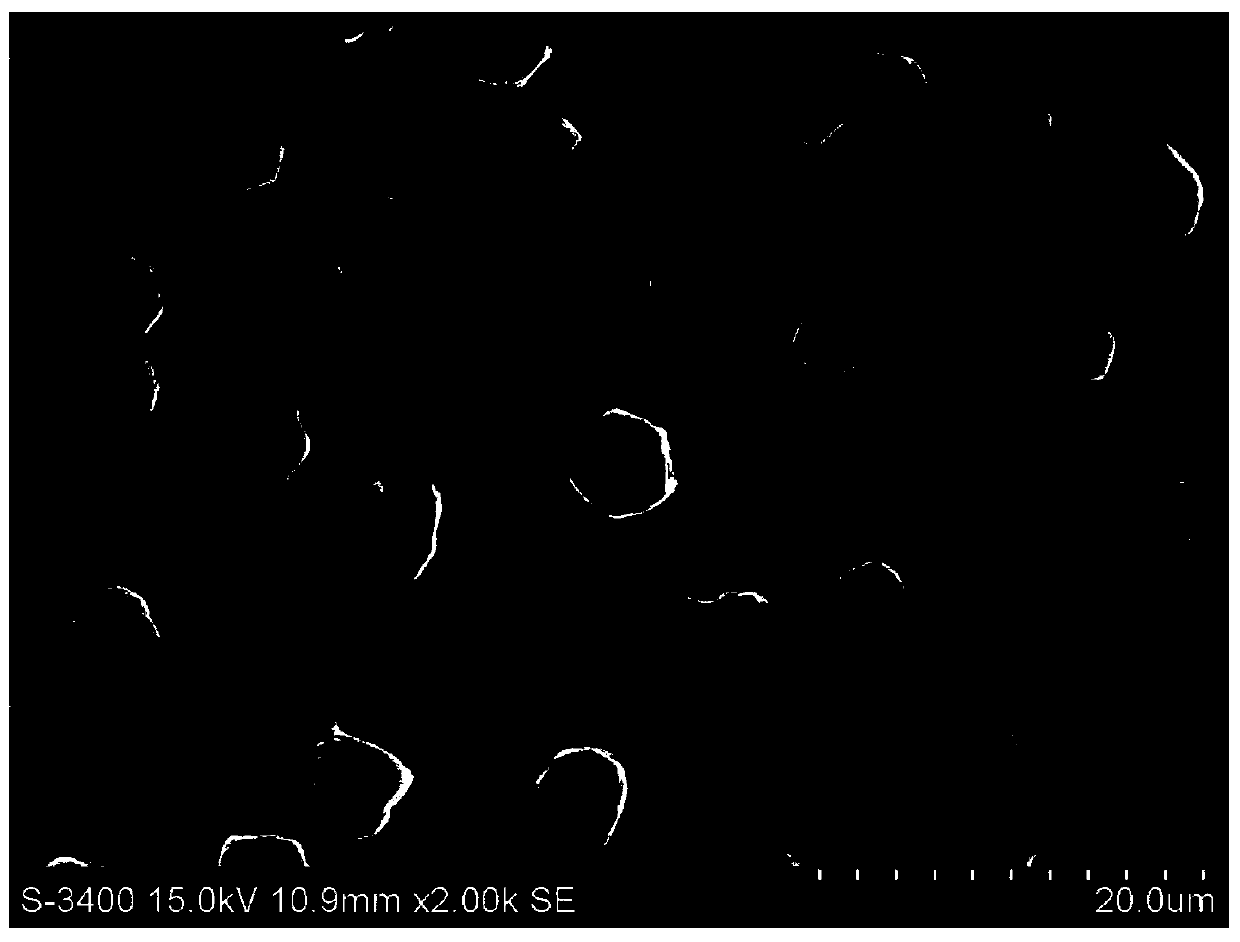

[0045] (1) Ultrasonic pickling treatment is performed on a pure titanium metal sheet of 10mm×10mm×1mm. The pickling solution is mixed with hydrofluoric acid, nitric acid and ultrapure water at a volume ratio of 1:5:34; followed by deionization Ultrasonic cleaning of water to obtain a clean and uniform surface (see figure 1 shown). Micro-arc oxidation technology is used to in-situ oxidize the titanium metal surface to form a porous titanium oxide coating. The specific process conditions and parameters are shown in Table 1. The surface topography images obtained under the process parameters are shown in Figure 2a As shown, the results show that the titanium metal surface forms a porous structure;

[0046] Table 1 is the micro-arc oxidation process conditions and parameters in the present embodiment 1:

[0047] Electrolyte 0.2M sulfuric acid solution oxidation voltage 270V electric current 1.8A frequency 800Hz duty cycle 10% oxidatio...

Embodiment 2

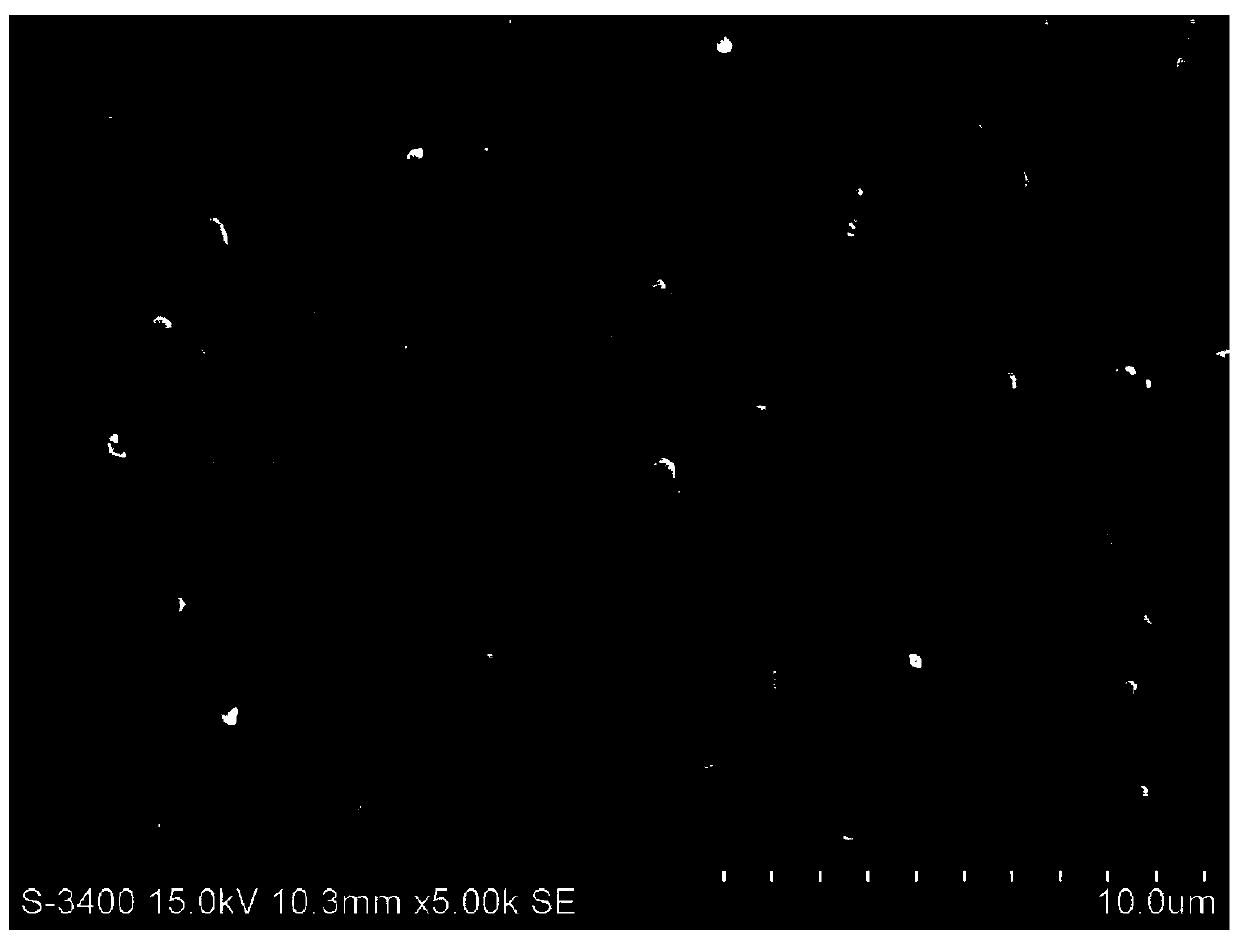

[0055] Step (1) of this embodiment is the same as that of Embodiment 1, and its detailed description is omitted. (2) Plasma immersion ion implantation was performed on the porous titanium oxide coating obtained by treating the titanium metal surface with the micro-arc oxidation technique in the above-mentioned embodiment 1. The specific injection parameters are shown in Table 3; the surface topography obtained under the injection parameters is shown in Figure 3b As shown, it can be seen from the figure that the surface of the coating still maintains the porous structure of the micro-arc oxidation coating after hydrogen ion implantation treatment;

[0056] Table 3 shows the hydrogen ion implantation parameters in Example 2:

[0057] background vacuum 4.0×10 -3 Pa

Injection voltage 30kV pulse width 30μs Pulse frequency 100Hz injection time 60min RF power 400W hydrogen 15 sccm

[0058] .

[0059] The reduced titaniu...

Embodiment 3

[0061] Step (1) of this embodiment is the same as that of Embodiment 1, and its detailed description is omitted. (2) Plasma immersion ion implantation was performed on the porous titanium oxide coating obtained by treating the titanium metal surface with the micro-arc oxidation technique in the above-mentioned embodiment 1. The specific injection parameters are shown in Table 4; the surface topography obtained under the injection parameters is shown in Figure 3c As shown, it can be seen from the figure that the surface of the coating still maintains the porous structure of the micro-arc oxidation coating after hydrogen ion implantation treatment;

[0062] Table 4 is the hydrogen ion implantation parameters in the present embodiment 3:

[0063] background vacuum 4.0×10 -3 Pa

Injection voltage 30kV pulse width 30μs Pulse frequency 100Hz injection time 120min RF power 400W hydrogen 15 sccm

[0064] .

[0065] The re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com