PGS/SF electrospinning membrane and preparation method thereof

An electrospun membrane and electrospinning technology, which is applied in the field of PGS/SF electrospun membrane and its preparation, can solve problems such as unknown properties, achieve good mechanical strength, great application potential, and promote adhesion and proliferation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Synthesis of PGS prepolymer: Take 0.1mol of sebacic acid and 0.1mol of glycerin into a 250mL three-necked flask, place it on a magnetic stirrer to stir and heat the reaction, feed nitrogen at room temperature, heat in an oil bath, and stir at 125°C After heating for 4 hours, the monomers were completely melted and mixed uniformly. The reaction was continued for 48 h while maintaining the temperature under a nitrogen atmosphere to obtain a PGS prepolymer. Cooled to room temperature to white waxy solid, stored at 4-8°C for later use.

[0045] The synthetic route of PGS is as follows, wherein n=6-50:

[0046]

[0047] (2) Preparation of SF membrane: Weigh 21.2g of anhydrous sodium carbonate and dissolve it in 10L of deionized water that has been heated and boiled, then degumming 25g of silkworm silkworm silk at 100°C for 30min, and take it out with deionized water after degumming is complete Repeat washing five times to remove residual sericin. After the filament...

Embodiment 2

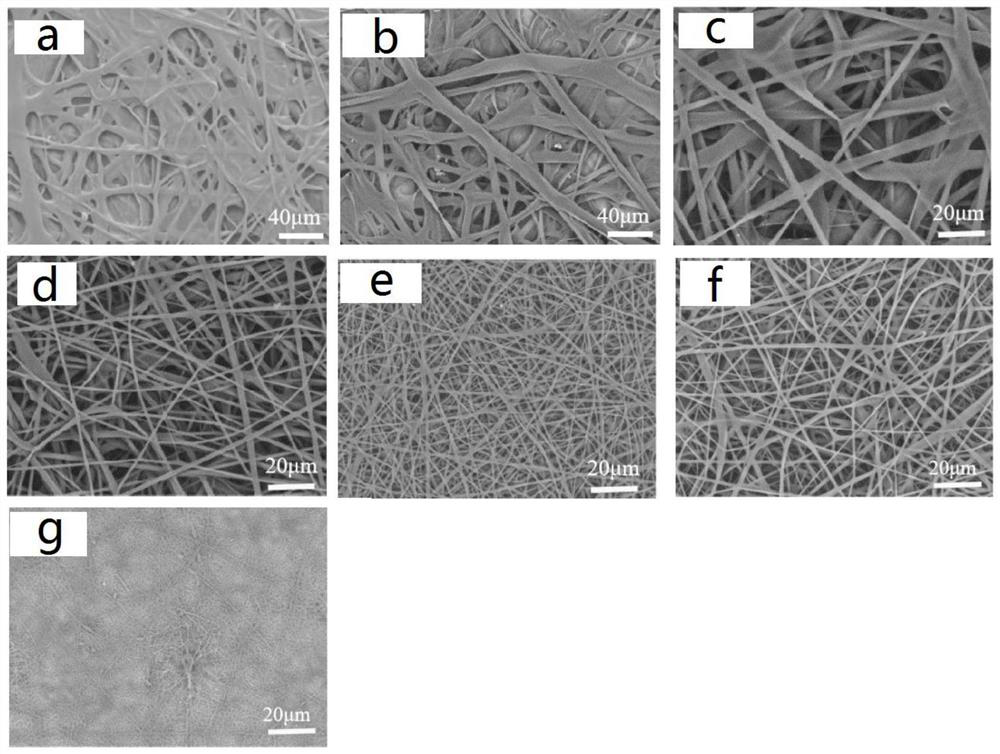

[0052] Prepare PGS / SF electrospun membrane according to the method of Example 1, the difference is that in step (3), the concentration of spinning solution is 9%, and the mass ratio of PGS and SF is 70 / 30, 50 / 50, 30 / 70, 0 / 100, the electrospinning parameters are the same as in Example 1. When the dissolved PGS content exceeds 70%, the concentration of the spinning solution is low and it is difficult to form by electrospinning, so the highest PGS content is selected to be 70%.

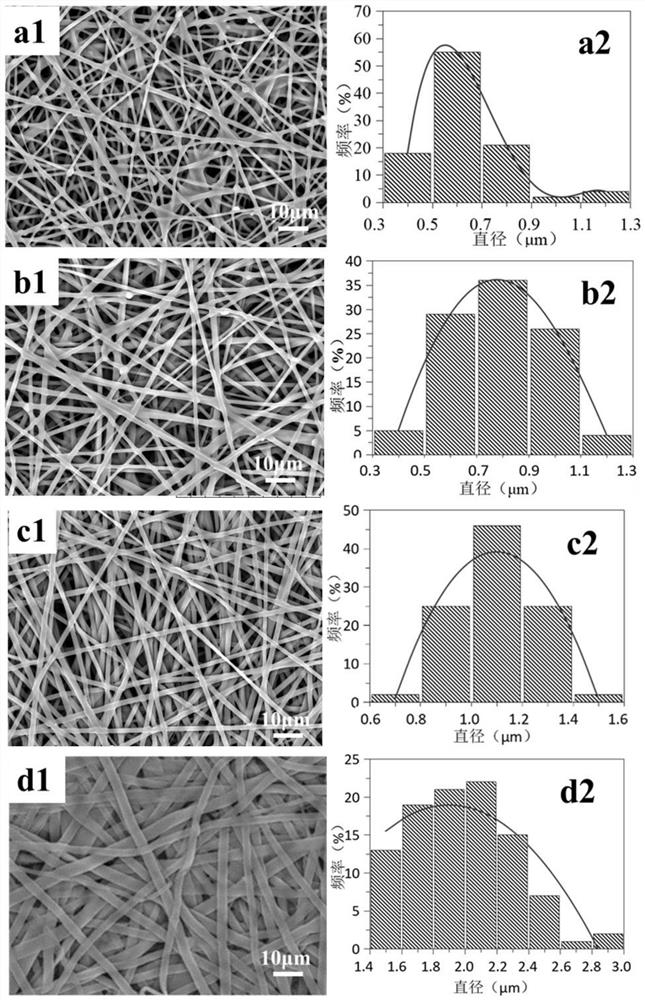

[0053] The SEM images of PGS / SF electrospun membranes with different mass ratios at the same concentration figure 2 shown. The PGS / SF electrospun materials of various mass ratios were composed of randomly distributed fibers, and the fiber diameter of the pure SF electrospun membrane was the largest, with an average diameter of 1.998 μm ( figure 2 d1, d2), when the PGS / SF ratio is 70 / 30, the average fiber diameter is 0.597μm ( figure 2 a1, a2), when the PGS / SF ratio is 50 / 50, the fiber diameter is ...

Embodiment 3

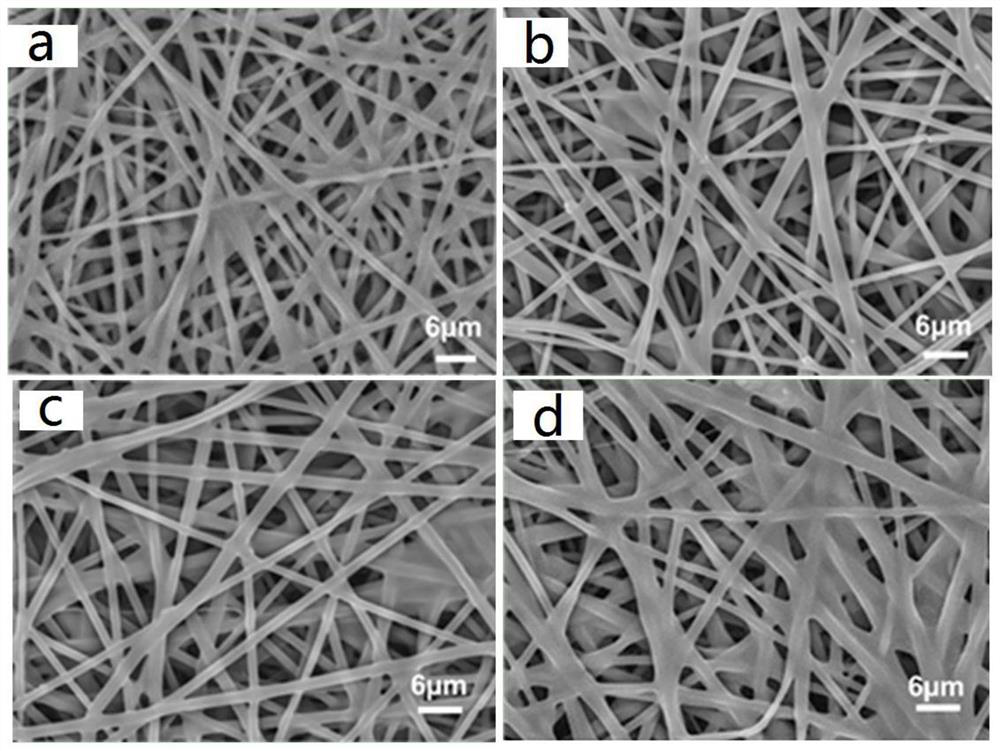

[0055] In order to investigate the influence of solidification time on the PGS / SF electrospun membrane, the PGS / SF electrospun membrane was prepared according to the method of Example 1, the difference being that in step (3), the concentration of the spinning solution was 9%, PGS and The mass ratio of SF was 50 / 50; in step (4), the electrospun membrane was dried and cured in a vacuum oven at 120°C for 6h, 12h, 18h, and 24h, respectively.

[0056] Such as image 3 as shown, image 3 a-d are SEM test images of PGS / SF electrospun membranes dried and cured at 120°C for 6h, 12h, 18h, and 24h, respectively. With the prolongation of curing time, PGS melted, and some fibers appeared in the electrospun membrane. After curing for 24 hours, the phenomenon of PGS melting was obvious, but the fiber morphology was clear.

[0057] The FTIR-ATR spectra of PGS / SF electrospun membranes with different curing times are as follows: Figure 4 shown. When the curing time is 0, 6, 12, 18, and 24h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com