Preparation method of collagen-hydroxyapatite artificial bone

A hydroxyapatite and artificial bone technology, applied in prosthesis, tissue regeneration, medical science and other directions, can solve the problem that the material can not fully meet the clinical repair and other problems, achieve the promotion of adhesion and proliferation, good mechanical properties, and improve the degree of deacetylation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

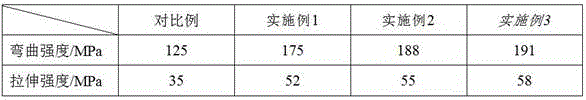

Examples

Embodiment 1

[0025] A preparation method of collagen-hydroxyapatite artificial bone, specifically comprising the following steps:

[0026] (1) Polylactic acid was prepared into a 1wt% solution with tetrahydrofuran;

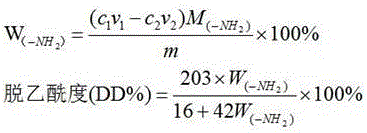

[0027] (2) Prepare chitosan, and prepare the prepared chitosan into a 0.02wt% solution with dilute acetic acid;

[0028] (3) Prepare a collagen solution with a concentration of 8g / L and a keratin solution with a concentration of 1g / L with distilled water;

[0029] (4) Add hydroxyapatite to the mixed solution of 8g / L collagen and 1g / L keratin, adjust the pH to 7.0 with sodium hydroxide solution, and add 1.5wt% genipin aqueous solution at 4 Cross-linking at ℃ for 2 hours to obtain mixed solution A, freeze-drying to obtain collagen / keratin / hydroxyapatite composite powder with a mass ratio of collagen, keratin and hydroxyapatite of 0.4:0.15:1, genipin aqueous solution Accounting for 1wt% of the total mass of the mixed solution A;

[0030] (5) Disperse the collagen / keratin / hydro...

Embodiment 2

[0033] A preparation method of collagen-hydroxyapatite artificial bone, specifically comprising the following steps:

[0034] (1) Polylactic acid was prepared into a 3wt% solution with tetrahydrofuran;

[0035] (2) Prepare chitosan, and prepare the prepared chitosan into a 0.05wt% solution with dilute acetic acid;

[0036] (3) Prepare a collagen solution with a concentration of 12g / L and a keratin solution with a concentration of 5g / L with distilled water;

[0037] (4) Add hydroxyapatite to the mixed solution of 12g / L collagen and 5g / L keratin, adjust the pH to 7.0 with sodium hydroxide solution, and add 1.5wt% genipin aqueous solution at 4 Cross-linking at ℃ for 2 hours to obtain mixed solution A, freeze-drying to obtain collagen / keratin / hydroxyapatite composite powder with a mass ratio of collagen, keratin and hydroxyapatite of 0.6:0.25:1, genipin aqueous solution Accounting for 1.5wt% of the total mass of the mixed solution A;

[0038] (5) Disperse the collagen / keratin / h...

Embodiment 3

[0041] A preparation method of collagen-hydroxyapatite artificial bone, specifically comprising the following steps:

[0042] (1) Polylactic acid was prepared into a 2wt% solution with tetrahydrofuran;

[0043] (2) Prepare chitosan, and prepare the prepared chitosan into a 0.03wt% solution with dilute acetic acid;

[0044] (3) Prepare a collagen solution with a concentration of 10g / L and a keratin solution with a concentration of 3g / L with distilled water;

[0045] (4) Add hydroxyapatite to the mixed solution of 10g / L collagen and 3g / L keratin, adjust the pH to 7.0 with sodium hydroxide solution, and add 1.5wt% genipin aqueous solution at 4 Cross-linking at ℃ for 2 hours to obtain mixed solution A, freeze-drying to obtain collagen / keratin / hydroxyapatite composite powder with a mass ratio of collagen, keratin and hydroxyapatite of 0.5:0.2:1, genipin aqueous solution Accounting for 1.2wt% of the total mass of the mixed solution A;

[0046] (5) Disperse the collagen / keratin / hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com