Bituminous concrete

An asphalt concrete and asphalt technology, applied in the field of asphalt concrete, can solve the problems of the impact of the compressive strength of the asphalt pavement and the service life of the asphalt pavement, so as to reduce the phenomenon of efflorescence, enhance the anti-ultraviolet performance and waterproof performance, and reduce the maintenance cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

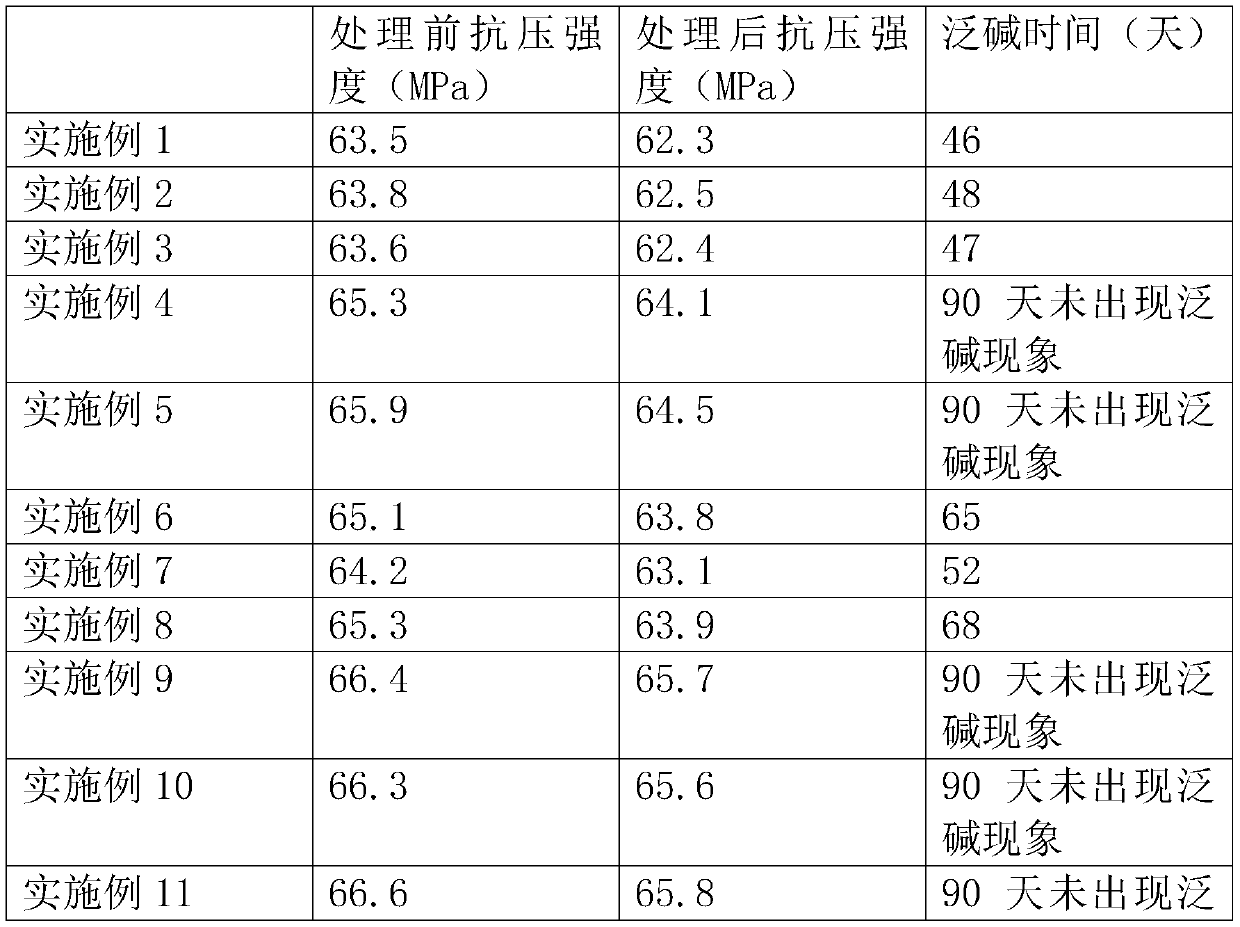

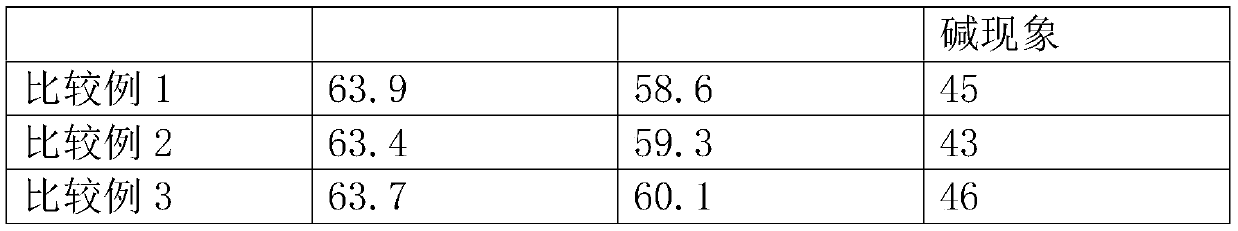

Examples

Embodiment 1

[0063] A kind of asphalt concrete, comprising the following components in parts by mass:

[0064] 80kg of asphalt; 20kg of Portland cement; 7kg of water reducer; 25kg of water; 50kg of sand; 38kg of stone; 20kg of methyl o-hydroxybenzoate; 1kg of cellulose triacetate;

[0065] The preparation method of asphalt concrete is as follows:

[0066] S1. Add 80kg of asphalt into a 250L mixing tank and heat to 140°C;

[0067] S2. Increase the temperature to 150°C, add 20kg of Portland cement, 7kg of water reducer, 25kg of water, 50kg of sand, 38kg of stone, 20kg of methyl o-hydroxybenzoate, 1kg of cellulose triacetate, and 7kg of acrylic emulsion while stirring. , and stir evenly to obtain asphalt concrete.

Embodiment 2

[0069] A kind of asphalt concrete, comprising the following components in parts by mass:

[0070] 85kg of asphalt; 15kg of Portland cement; 8kg of water reducer; 28kg of water; 45kg of sand; 40kg of stone; 18kg of methyl o-hydroxybenzoate; 2kg of cellulose triacetate;

[0071] The preparation method of asphalt concrete is as follows:

[0072] S1. Add 85kg of asphalt to a 250L mixing tank and heat to 140°C;

[0073] S2. Increase the temperature to 150°C, add 15kg of Portland cement, 8kg of water reducer, 28kg of water, 45kg of sand, 40kg of stone, 18kg of methyl o-hydroxybenzoate, 2kg of cellulose triacetate, and 8kg of acrylic emulsion while stirring. , and stir evenly to obtain asphalt concrete.

Embodiment 3

[0075] A kind of asphalt concrete, comprising the following components in parts by mass:

[0076] Asphalt 90kg; Portland cement 18kg; water reducing agent 5kg; water 30kg; sand 48kg; stone 35kg; methyl o-hydroxybenzoate 15kg; triacetate cellulose 3kg; acrylic emulsion 5kg.

[0077] The preparation method of asphalt concrete is as follows:

[0078] S1. Add 90kg of asphalt into a 250L mixing tank and heat to 140°C;

[0079] S2. Increase the temperature to 150°C, add 18kg of Portland cement, 5kg of water reducer, 30kg of water, 48kg of sand, 35kg of stone, 15kg of methyl o-hydroxybenzoate, 3kg of cellulose triacetate, and 5kg of acrylic emulsion while stirring. , and stir evenly to obtain asphalt concrete.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap