Sintering preparation method of semi-transparent alumina ceramic

A kind of alumina ceramics, translucent technology, applied in the field of ceramic sintering, can solve the problems of complicated process, production environment pollution, long premixing time, etc., and achieve the effect of excellent comprehensive performance, easy promotion and application, and simple overall process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

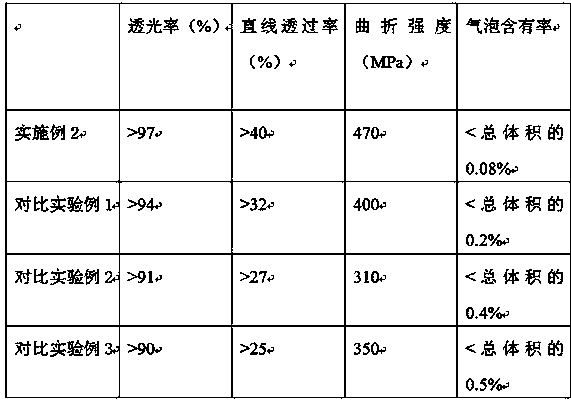

Examples

Embodiment 1

[0026] A method for preparing translucent alumina ceramics by sintering, comprising the steps of:

[0027] (1) Mix alumina powder and aluminum nitride powder, and then die-cast to obtain a ceramic body for use;

[0028] (2) Put the ceramic green body prepared in step (1) into a microwave sintering furnace for pre-sintering treatment, control the sintering temperature to 750°C, and control the duration to 2 hours, and take out the pre-sintered ceramic green body after completion;

[0029] (3) Put the pre-sintered ceramic green body prepared in step (2) into the variable temperature box for cooling treatment, take it out after the temperature drops to 50°C, and then immediately immerse it in the inhibitor solution for infiltration treatment, control the immersion The duration of the infiltration treatment is 4 hours, and after completion, the infiltrated ceramic body is taken out for subsequent use;

[0030] (4) Put the impregnated ceramic body prepared in step (3) into a const...

Embodiment 2

[0040] A method for preparing translucent alumina ceramics by sintering, comprising the steps of:

[0041] (1) Mix alumina powder and aluminum nitride powder, and then die-cast to obtain a ceramic body for use;

[0042] (2) Put the ceramic green body prepared in step (1) into a microwave sintering furnace for pre-sintering treatment, control the sintering temperature to 770°C, and control the duration to 3 hours, and take out the pre-sintered ceramic green body after completion;

[0043] (3) Put the pre-sintered ceramic green body prepared in step (2) into the variable temperature box for cooling treatment, take it out after the temperature drops to 55°C, and then immediately immerse it in the inhibitor solution for infiltration treatment, control the immersion The duration of the infiltration treatment is 6 hours, and after completion, the infiltrated ceramic body is taken out for subsequent use;

[0044] (4) Put the impregnated ceramic body prepared in step (3) into a const...

Embodiment 3

[0054] A method for preparing translucent alumina ceramics by sintering, comprising the steps of:

[0055] (1) Mix alumina powder and aluminum nitride powder, and then die-cast to obtain a ceramic body for use;

[0056] (2) Put the ceramic green body prepared in step (1) into a microwave sintering furnace for pre-sintering treatment, control the sintering temperature to 780°C, and control the duration to 4 hours, and take out the pre-sintered ceramic green body after completion;

[0057] (3) Put the pre-sintered ceramic green body prepared in step (2) into the variable temperature box for cooling treatment, take it out after the temperature drops to 60°C, and then immediately immerse it in the inhibitor solution for infiltration treatment, control the immersion The duration of the infiltration treatment is 7 hours, and after completion, the infiltrated ceramic body is taken out for subsequent use;

[0058] (4) Put the impregnated ceramic body prepared in step (3) into a const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com