Tire polishing protective agent and preparation method thereof

A light protection agent and tire technology, which is applied in paints, coatings, anti-fouling/underwater coatings containing biocide, etc., can solve the problems of non-hydrophobicity, poor resistance to rain washing, no weather resistance and pollution resistance, etc. problem, to achieve the effect of low surface tension, good atomization effect and good glazing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further illustrate the technical means adopted by the present invention and its effects, the following is a detailed description in conjunction with preferred embodiments of the present invention.

[0036] The present invention at first provides a kind of tire polishing protection agent, and the component that comprises and percentage by weight are as follows:

[0037] Polyether amino co-modified silicone polymer material: 10.0-15.0%;

[0038] Hydrophobic brightening accelerator: 0.5-1.0%;

[0039] Builder: 2.0~10.0%;

[0040] Deionized water: 60-80%;

[0041] Flavor: 0.1~0.5%;

[0042] Water-based UV absorber: 0.1-0.5%;

[0043] Propellant: 10% to 15%; among them,

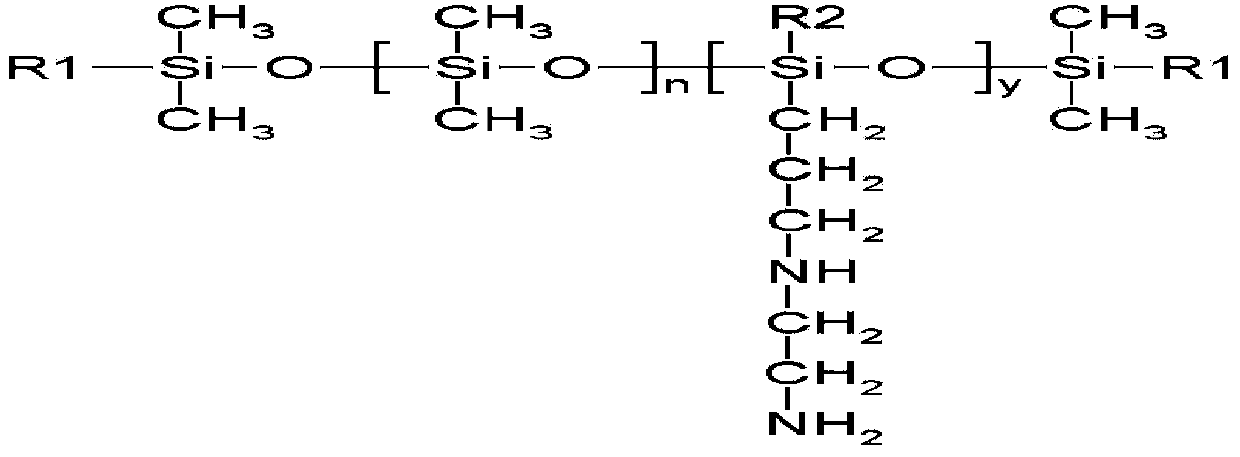

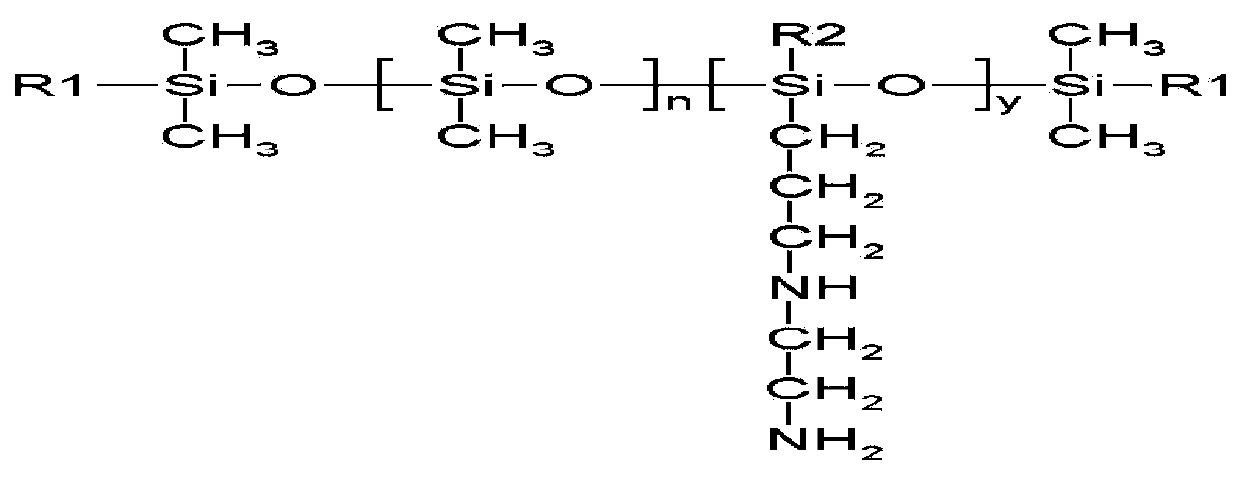

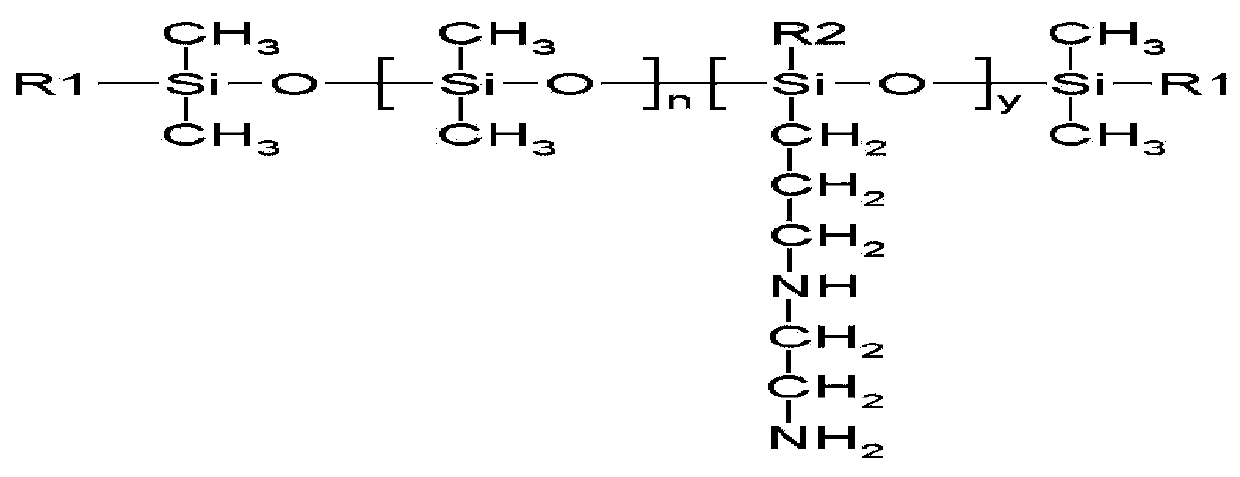

[0044] The viscosity of the polyether amino co-modified silicone polymer material is 2000-5000mPa·s, the ammonia value is less than 0.2mmol / L, and the structure is as follows:

[0045]

[0046] where R1 is CH 3 , R2 is alkyl ethoxy ether R-O-(-CH- 2 CH 2 -O-)n- - .

[0047] Specifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com