Preparation method of low-melting-point copolyamide hot melt adhesive

A technology of copolyamide and hot-melt adhesive, which is applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc. It can solve the problems of unsuitable bonding of high-grade fabrics, poor washing resistance, and low bonding strength. , to achieve rapid and effective response, good bonding effect and low melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

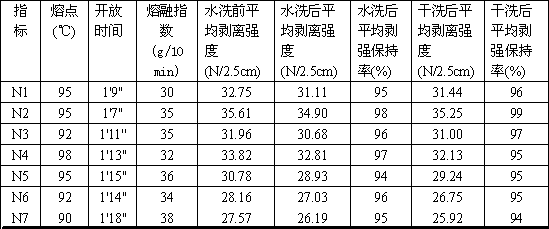

Examples

Embodiment 1

[0023] A preparation method of low melting point copolyamide hot melt adhesive, the steps are as follows:

[0024] (1) Mix 98 g caprolactam, 116.91 g adipic acid, 70.79 g sebacic acid, 103.64 g dodecanedioic acid, 94.8 g hexamethylenediamine, 77.54 g decanediamine, 90.16 g dodecanediamine, 0.65 g Stearic acid, 1.96 g of antioxidant and 13 g of water were added to the reaction kettle, and nitrogen was replaced 3 times at first; then the temperature was slowly raised to 120°C, stirring was started, the temperature was continued to rise to 230°C, and the pressure was kept rising, at a pressure of 1.3MPa Reaction for 1.5h at ~1.5MPa, temperature 230℃~250℃;

[0025] (2) Reduce to normal pressure, add 1.3g of talc powder, react for 2 hours at a temperature of 230°C~250°C, and then pressurize and discharge to obtain the product.

[0026] The sample obtained in Example 1 is designated as N1.

Embodiment 2

[0028] A preparation method of low melting point copolyamide hot melt adhesive, the steps are as follows:

[0029] (1) 196 g caprolactam, 120.57 g adipic acid, 59.47 g undecanedioic acid, 67.19 g tridecanedioic acid, 80.19 g 2-methyl-1,5-pentanediamine, 54.11 g decanedidiamine, 75.34 g of dodecanediamine, 3.26 g of stearic acid, 0.33 g of antioxidant and 10 g of water were added to the reaction kettle, and the nitrogen was replaced 3 times at first; the temperature was slowly raised to 120°C, the stirring was started, and the temperature was continued to rise to 230°C. Keep the pressure rising continuously, and react for 1.5h under the conditions of pressure 1.3MPa~1.5MPa and temperature 230℃~250℃;

[0030] (2) Decrease to normal pressure, add 3.26 g of fumed silica, react at a temperature of 230°C to 250°C for 2 hours, and then pressurize and discharge.

[0031] The sample obtained in Example 2 is designated as N2.

Embodiment 3

[0033] A preparation method of low melting point copolyamide hot melt adhesive, the steps are as follows:

[0034] (1) 105 g caprolactam, 131.53 g adipic acid, 68.97 g sebacic acid, 105.67 g tetradecanedioic acid, 99.3 g hexamethylenediamine, 88.4 g decanediamine, 102.8 g dodecanediamine, 3.51 g Add stearic acid, 0.35 g antioxidant and 14 g water into the reaction kettle, and replace with nitrogen three times at first; slowly raise the temperature to 120°C, start stirring, continue to raise the temperature to 230°C, and keep the pressure rising continuously, at a pressure of 1.3MPa~ Reaction for 1.5h under the conditions of 1.5MPa and temperature 230℃~250℃;

[0035] (2) Reduce to normal pressure, add 3.51g of nano-calcium carbonate, react at a temperature of 230°C to 250°C for 2 hours, and then pressurize and discharge.

[0036] The sample obtained in Example 3 is designated as N3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com