Gold extracting agent and gold extracting process using same

A chemical and process technology, applied in the field of hydrometallurgy, can solve the problems of low gold recovery rate, large chemical consumption, imperfect leaching follow-up process, etc., and achieve the effect of accelerating gold leaching reaction, reducing energy consumption, and rapid and efficient reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

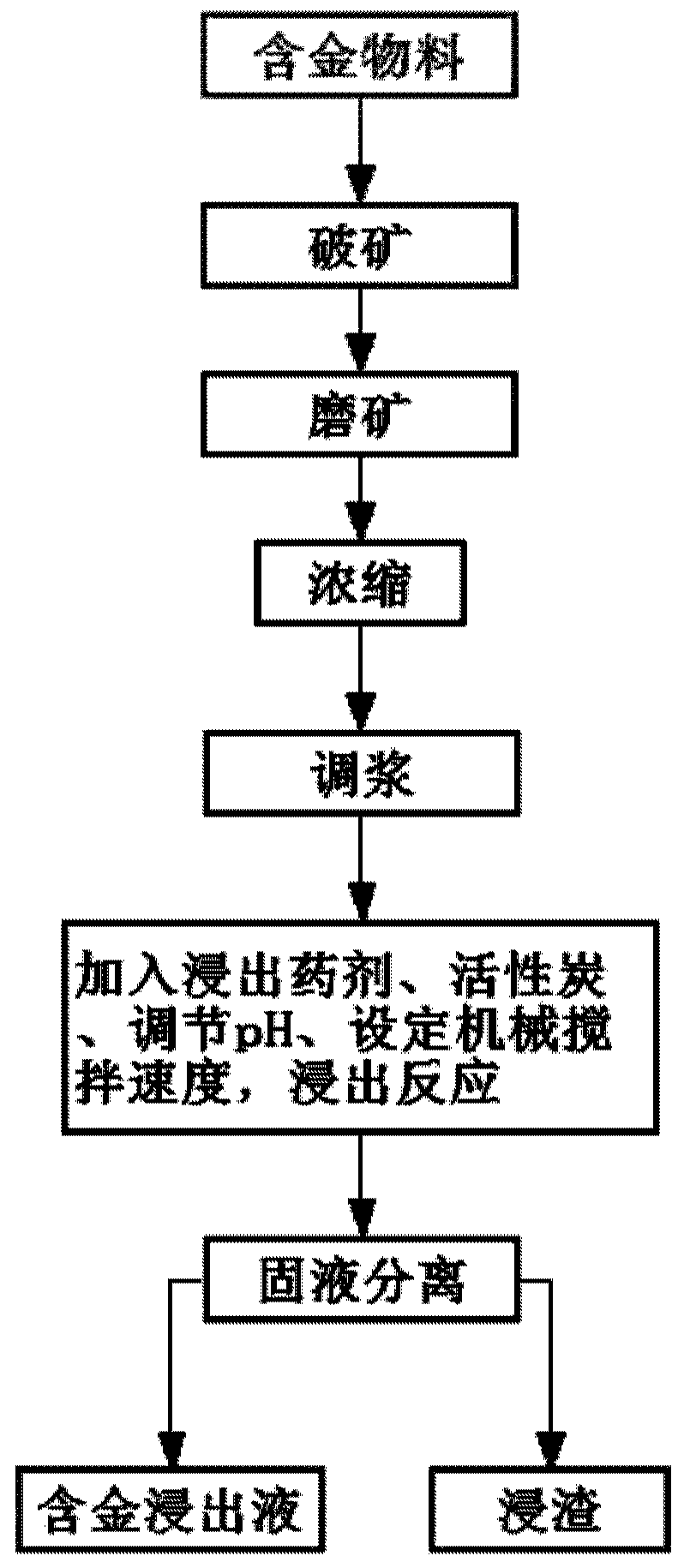

Method used

Image

Examples

Embodiment 1~6

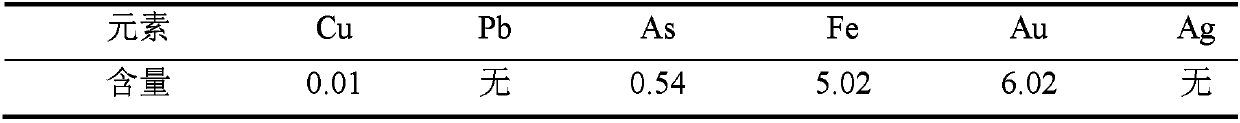

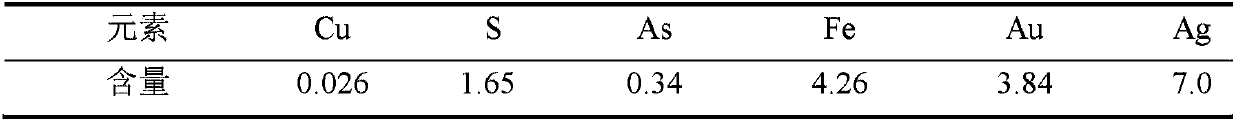

[0060] Embodiments 1 to 6 of the present invention provide six groups of ore samples of different types and properties as gold-bearing materials in wet gold extraction experiments. The specific operations are as follows:

[0061] (1) Ore breaking: each group of gold-bearing materials is fully crushed in the two-stage crushing and two-stage screening closed-circuit crushing system composed of jaw crusher, double-roller crusher and 2mm sieve. After screening, the materials larger than 2mm are returned The roller crusher continues to crush, and the material smaller than 2mm is used as grinding material.

[0062] (2) Grinding: After the ore is broken, feed the material less than 2mm obtained in step (1) into a roller ball mill for grinding, and set the ball milling time according to the occurrence state of gold in different minerals and the fragility of the minerals. Grind until the particle size composition is less than 200 mesh (less than 0.074mm) accounting for more than 95%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com