Preparation and application of lithium metal anode with composite film

A lithium metal negative electrode and composite film technology, which is applied in the direction of battery electrodes, non-aqueous electrolyte battery electrodes, structural parts, etc., can solve the problems of lithium dendrites, cycle life reduction, lithium deposition and pulverization, etc., and achieve the goal of reducing dead lithium Produce, prolong cycle life, and reduce lithium consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Carbonized polyacrylonitrile, lithium nitrate, and acrylonitrile copolymer were uniformly mixed in a mass ratio of 8:1:1 with water as a solvent to form a slurry, which was coated on a copper foil current collector with a coating thickness of 10 μm. After the solvent evaporates, the copper foil is punched into a pole piece with a diameter of 16mm. The pole piece, separator, and lithium metal were assembled into a button cell in an argon-protected glove box, and an electrolyte solution of ethylene carbonate and diethyl carbonate (volume ratio 1:1) with a concentration of 1M lithium hexafluorophosphate was added.

[0037] The button cell assembled by the above method was charged at 0.5mA / cm 2 Discharge for 20 hours at a current density of 10 mAh / cm on the surface of the current collector 2 of lithium metal. After the discharge is completed, the above-mentioned button battery is disassembled, and the current collector deposited with lithium metal is taken out, such as f...

Embodiment 2

[0039] Carbonized polyacrylonitrile, lithium nitrate, and acrylonitrile copolymer were uniformly mixed in a mass ratio of 8:1:1 with water as a solvent to form a slurry, which was coated on a copper foil current collector with a coating thickness of 10 μm. After the solvent evaporates, the copper foil is punched into a pole piece with a diameter of 16mm. The pole piece, separator, and lithium metal were assembled into a button cell in an argon-protected glove box, and an electrolyte solution of ethylene carbonate and diethyl carbonate (volume ratio 1:1) with a concentration of 1M lithium hexafluorophosphate was added.

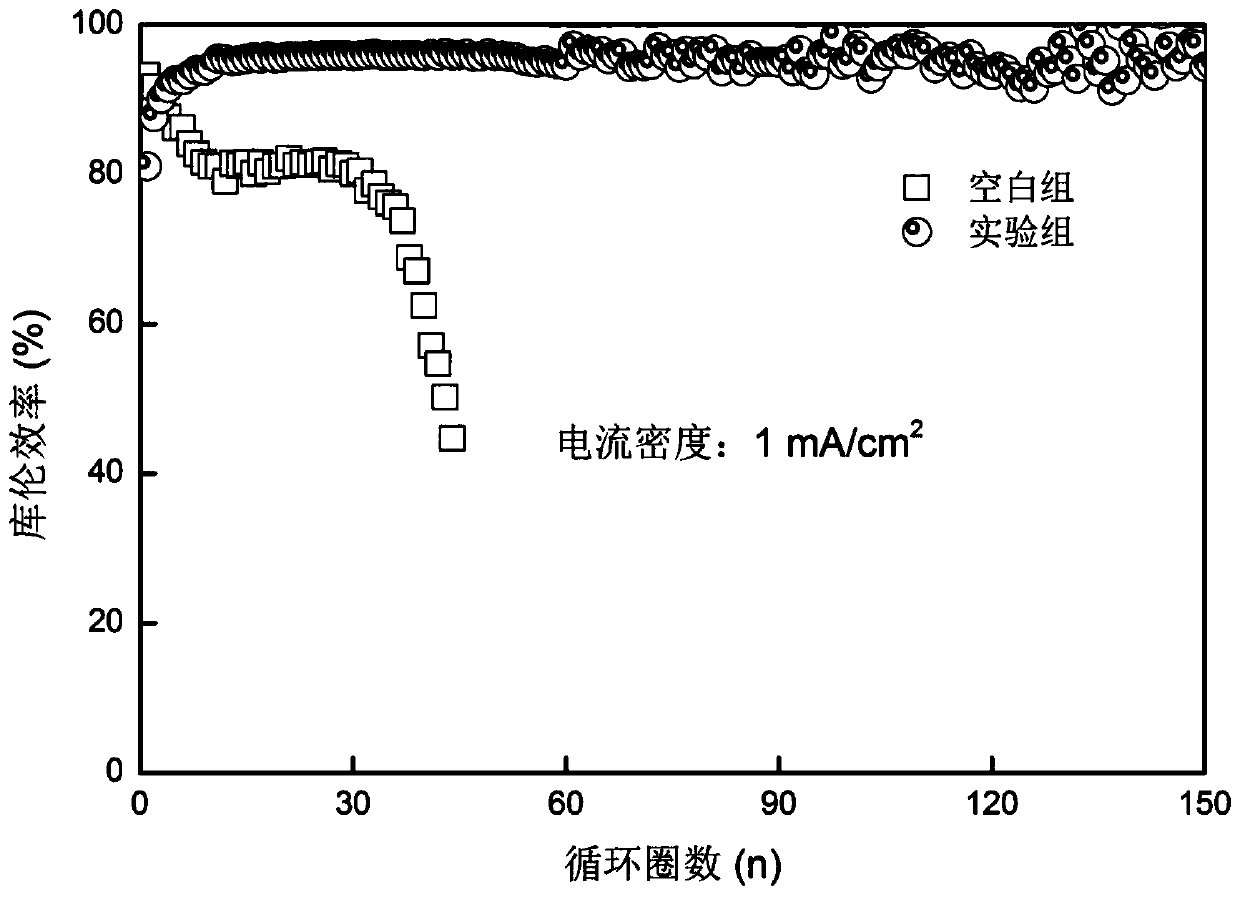

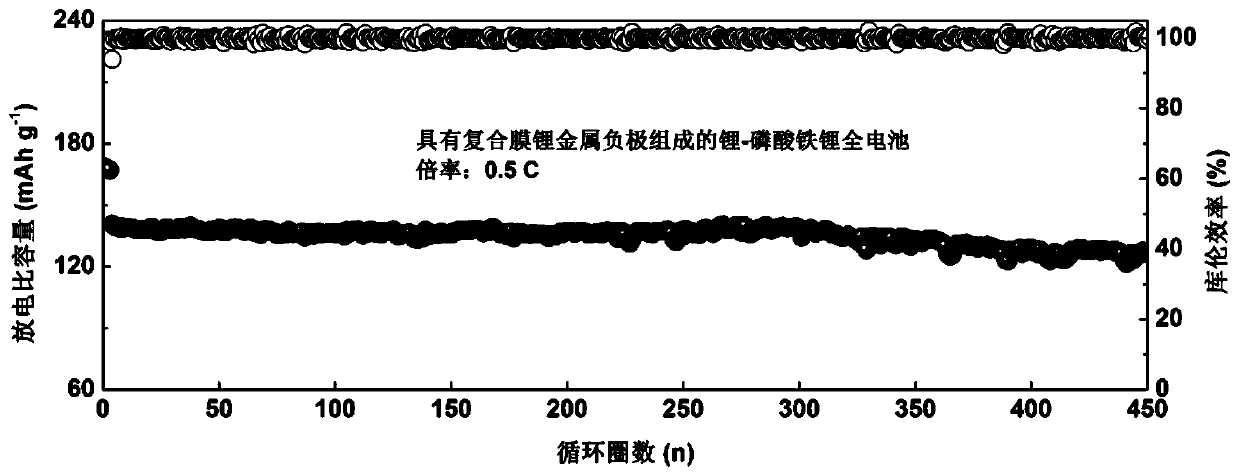

[0040] The button cell assembled by the above method was charged at 1mA / cm 2 The Coulombic efficiency test is carried out at a current density of 100,000 to make lithium repeatedly deposited and stripped on the copper foil covered with a composite film, and the Coulombic efficiency is obtained by the amount of lithium deposited and stripped per cycle, as shown ...

Embodiment 3

[0043] The selected inorganic substance is lithium fluoride. All the other are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com