Silicon-carbon composite material water-based composite slurry and preparation method thereof, and lithium ion battery

A technology of silicon-carbon composite materials and composite slurry, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor strength of SBR emulsion and the inability to apply Si-based system materials, etc., to suppress volume expansion effect and improve distribution Uniformity, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

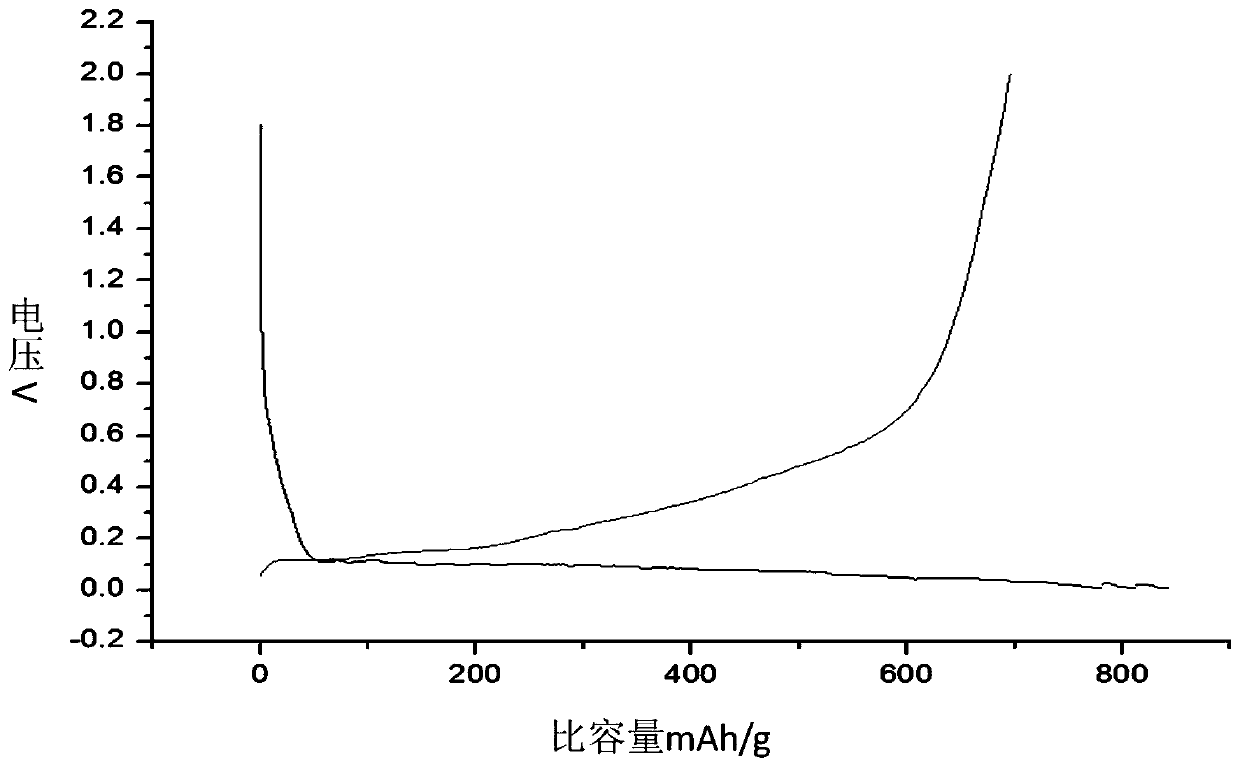

Embodiment 1

[0047] Preparation of water-based composite slurry for silicon-carbon composite materials:

[0048] 1) Take 1.7g of powdered silicon-carbon composite material (650mAh / g) and 0.1g of conductive carbon black and use a planetary rotor mixer to stir the dry powder for 30 minutes; wherein, the revolution speed is 2000r / min;

[0049] 2) Add 1.3 g of deionized water and 1.6 g of sodium carboxymethylcellulose colloid (5% content) to the dry powder mixed in step (1), soak and stir in a planetary rotor mixer for 20 minutes to obtain a uniform primary Slurry, control the total solid content ratio at about 45%; among them, the revolution speed of immersion stirring is 1500r / min;

[0050] 3) Continue to add a mixed emulsion of 0.12 g of styrene-butadiene rubber emulsion (50% content) and 0.2 g (30% content) of polyacrylic acid emulsion to the slurry after soaking and stirring, stir at a medium speed for a short time and defoam 2min (the revolution speed of defoaming is 1000-1200r / min), le...

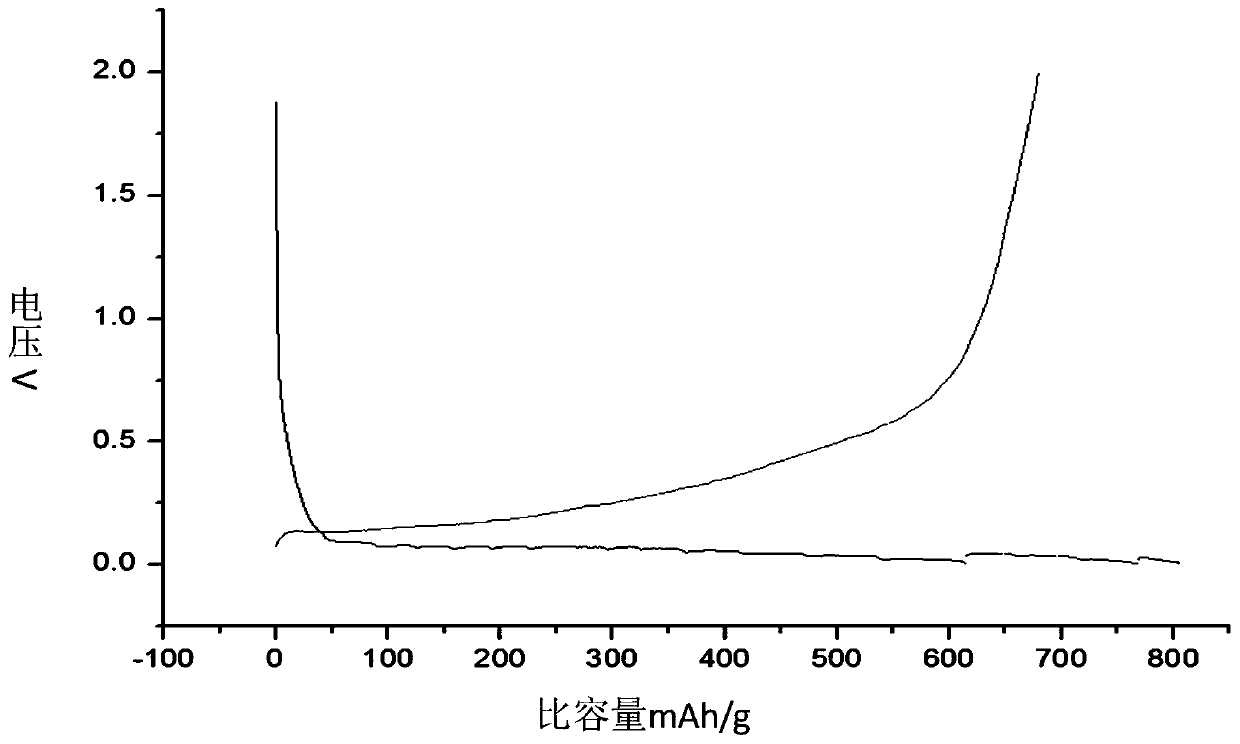

Embodiment 2

[0054] Preparation of water-based composite slurry for silicon-carbon composite materials:

[0055] 1) Take 3.72g of powdered silicon-carbon composite material (with a capacity of 450mAh / g) and 0.08g of conductive carbon black and use a planetary rotor mixer to stir the dry powder for 25 minutes; wherein, the revolution speed is 2200r / min;

[0056] 2) Add 1.6 g of deionized water and sodium carboxymethylcellulose colloid (5% content) to the dry powder mixed in step (1), soak and stir in a planetary rotor mixer for 30 minutes to obtain a uniform primary slurry , control the total solid content ratio at about 45%; wherein, the revolution speed of immersion stirring is 1000r / min;

[0057] 3) Continue to add a mixed emulsion of 0.12 g (content: 60%) of styrene-butadiene rubber emulsion and 0.2 g (content: 30%) of polyacrylic acid emulsion to the slurry after soaking and stirring, carry out medium-speed short-term stirring and defoaming 1min (the revolution speed of defoaming is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com