Porphyrin-based polymer-of-intrinsic-microporosity and synthesis method thereof

A microporous polymer and porphyrin-based technology, which is applied in the field of porphyrin-based microporous polymers and their synthesis, can solve the problems of difficult modification of active sites, unstable active sites, and limited applications. Rich pore size distribution, conducive to large-scale mass production, and the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

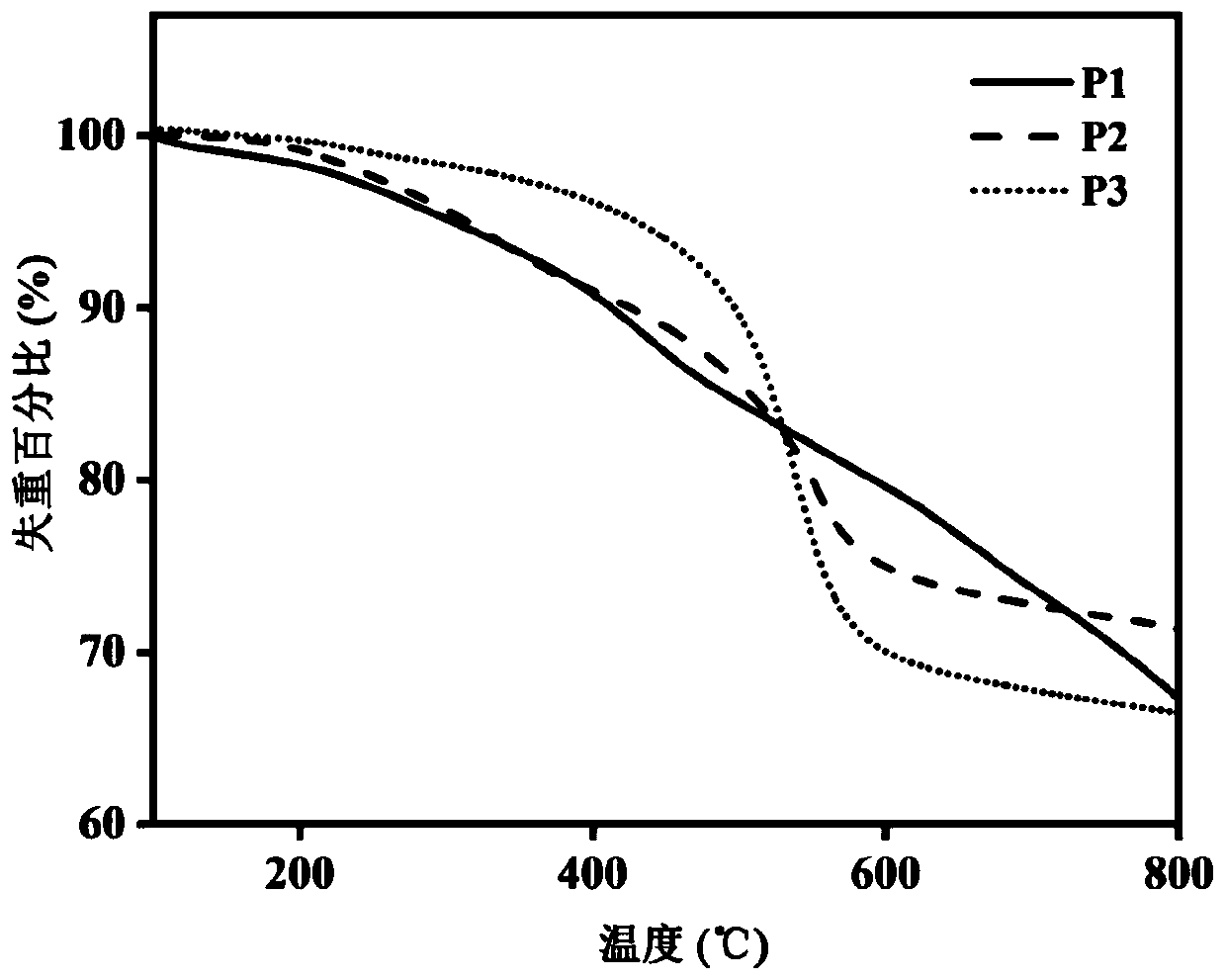

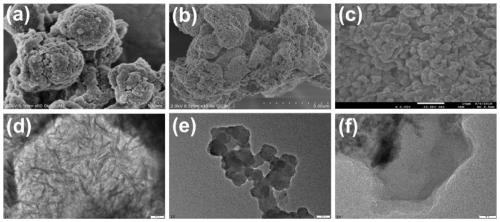

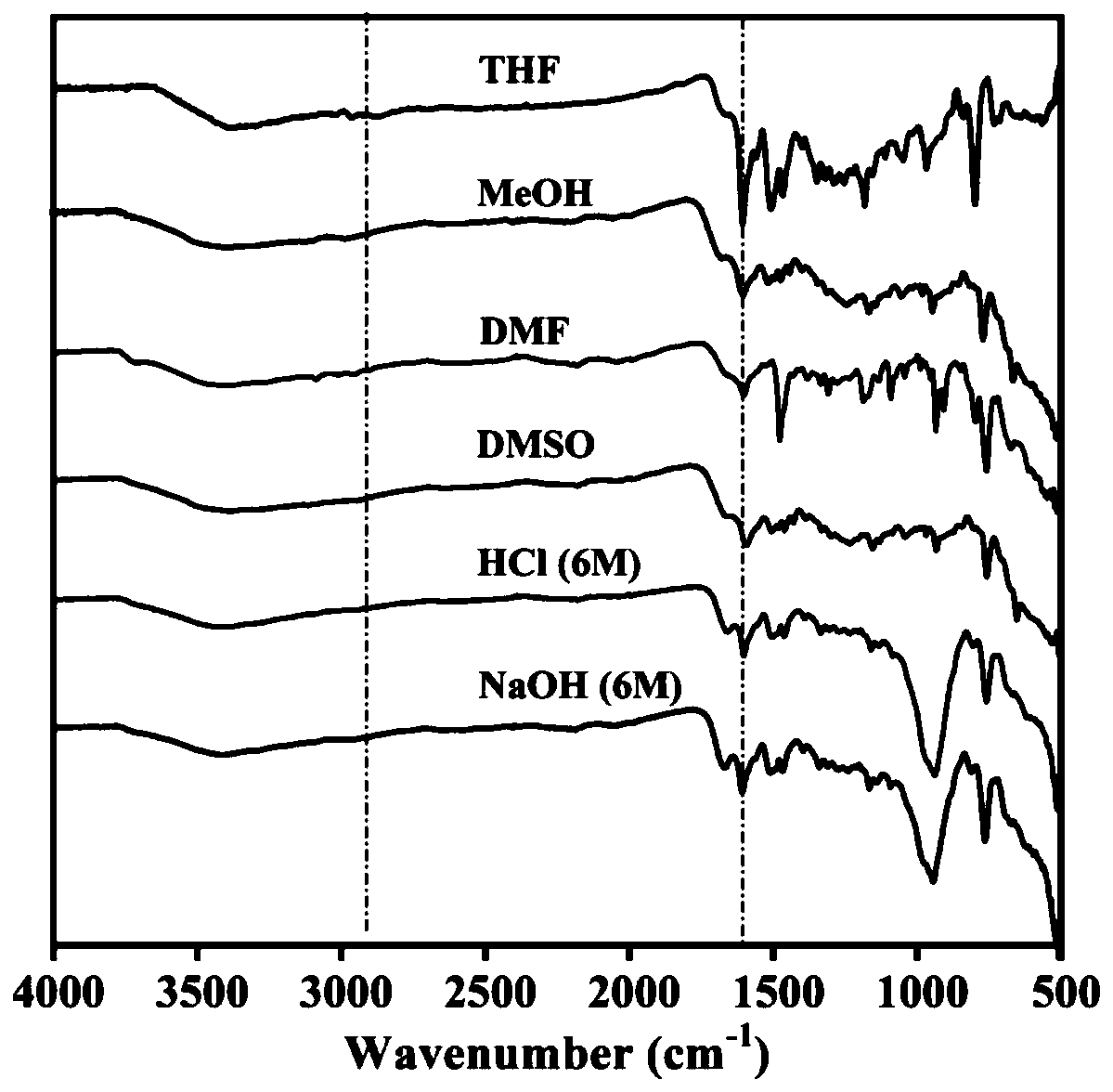

[0037] The synthetic steps of present embodiment polymer P1 are as follows:

[0038] 1) Under the conditions of argon protection and ice-water bath, the porphyrin-based P1 was synthesized by a one-pot method, and 193.4 mg of 5,15-bis(4-aminophenyl)-10,20 was weighed into a 25 mL round bottom flask -diphenylporphyrin (B10) (0.3mmol), then add 10mL of trifluoroacetic acid to the bottle, stir for 5 minutes, after B10 is uniformly dispersed, add 0.132mL of dimethylformal to the solution, and react at room temperature 3 days.

[0039] 2) After the reaction is finished, slowly add 2.5% ammonia water dropwise to the blue-black solution to quench the reaction until the pH of the solution is adjusted to 7-8, continue to stir for 4 hours, the solution becomes viscous, pour the reaction solution into 400mL methanol solution , settling to settle for half an hour, and filtered with suction to obtain a blue-black solid.

[0040] 3) Rinse the obtained solid three to five times with deioniz...

Embodiment 2

[0045] The synthetic steps of present embodiment polymer P2 are as follows:

[0046] 1) Under the conditions of argon protection and ice-water bath, the porphyrin-based P2 was synthesized by a one-pot method, and 202.4 mg of 5,10,15,20-tetraaminophenylporphyrin (TAPP ) (0.3 mmol), and then add 10 mL of trifluoroacetic acid into the bottle, and stir for 5 minutes. After TAPP is uniformly dispersed, add 0.265 mL of dimethylformal to the solution, and react at room temperature for 5 days.

[0047] 2) After the reaction is completed, slowly add 2.5% ammonia water dropwise to the blue-black solution to quench the reaction until the pH of the solution is adjusted to 7-8, and continue to stir for 3 hours. The solution becomes viscous and black solids are precipitated. Pour it into 500mL of methanol solution, let it settle for half an hour, and filter it with suction to obtain a blue-black solid.

[0048] 3) Rinse the obtained solid three times with deionized water and three times wi...

Embodiment 3

[0053] The synthesis of present embodiment polymer P3 is as follows:

[0054]

[0055] 1) Under the conditions of argon protection and ice-water bath, use a one-pot method to synthesize porphyrin-based P3, and weigh 293.5 mg of 5,10,15,20-tetrakis(4-aminobiphenyl) into a 25mL round bottom flask )-21H,23H-porphyrin (B11) (0.3mmol), then add 10mL of trifluoroacetic acid to the bottle, stir for 5 minutes, after B11 is uniformly dispersed, add 0.265mL dimethylformal to the solution, at room temperature The next reaction was 4 days.

[0056] 2) After the reaction is completed, slowly add 2.5% ammonia water dropwise to the blue-black solution to quench the reaction until the pH of the solution is adjusted to 7-8, and continue to stir for 4 hours. Black solids are precipitated from the solution, and the reaction solution is poured into 400 mL of methanol The solution was left to settle for half an hour, and filtered with suction to obtain a blue-black solid.

[0057] 3) The obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com