An online detection system and online detection method for the quality of a bamboo bundle integrated veneer

A detection method and detection system technology, applied in the direction of applying stable tension/pressure to test material strength, specific gravity measurement, measuring device, etc., can solve problems such as uneven local density, inability to guarantee product quality stability, and inhomogeneity , to achieve the effects of reducing human resource requirements, realizing automated production and testing, and strong ability to resist ambient light interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

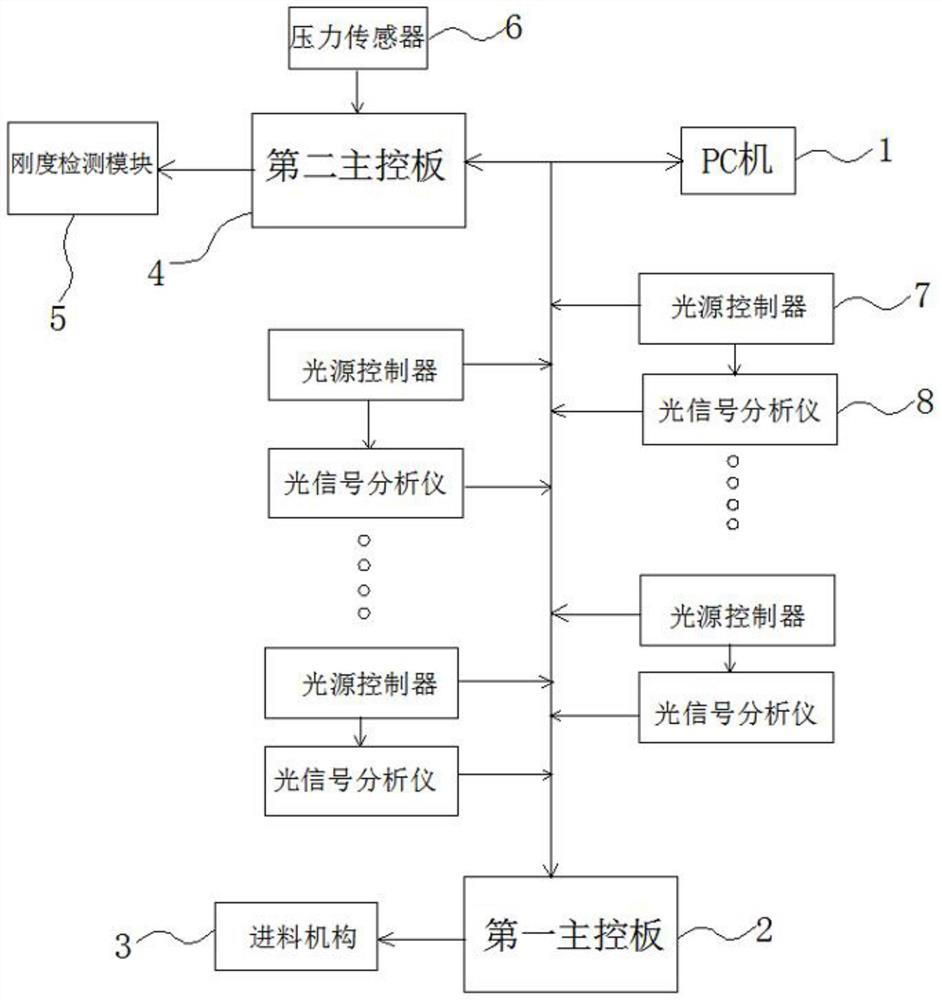

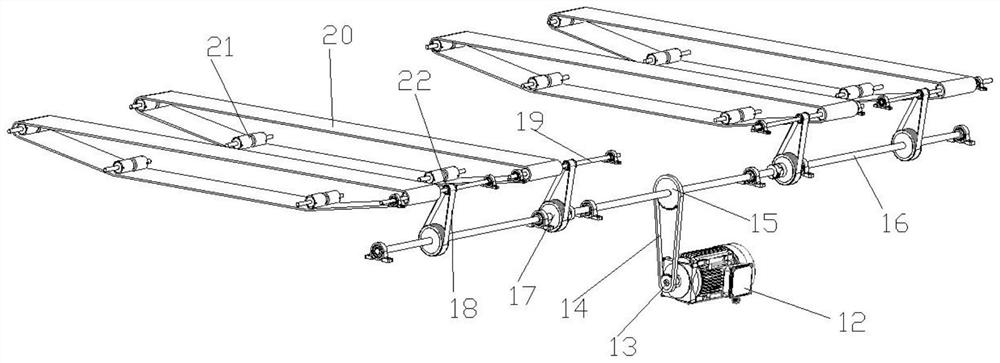

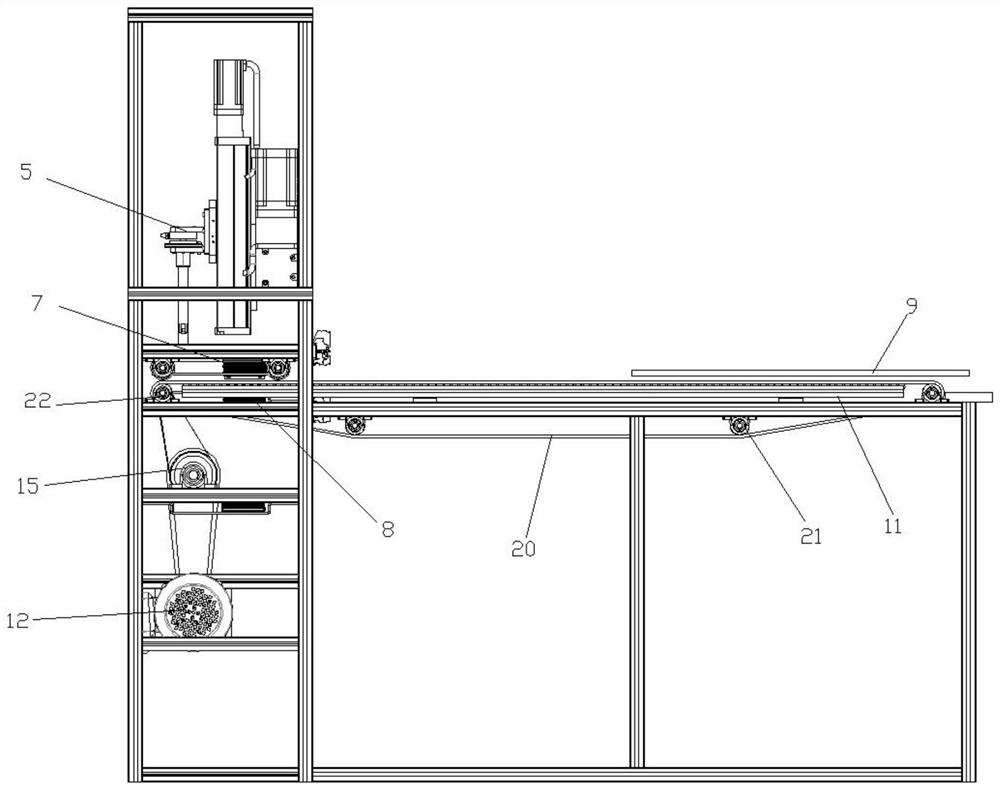

[0047] Such as figure 1 and figure 2 As shown, the present invention includes a PC machine 1, and a first main control board 2 and a second main control board 4 respectively connected to the PC machine 1, the first main control board 2 is connected to the feeding mechanism 3, and the first main control board 2 The main control board 2 controls the horizontal advance displacement of the feed mechanism 3, and the feed mechanism 3 is fixedly installed on the support frame; multiple groups are connected between the first main control board 2 and the PC machine 1 for detecting bamboo bundles. The density detection module of the integrated veneer 9 density, multiple groups of density detection modules are horizontally arranged on the support frame, and the horizontal layout direction of the multiple groups of density detection modules is the same as that of the whole bamboo bundle veneer 9 The horizontal advance direction is vertical, and the density detection module includes a li...

Embodiment 2

[0056] In this embodiment, the online detection system for the quality of the whole bamboo bundle veneer is used for online detection of the quality of the whole bamboo bundle veneer. The detection method includes the following steps:

[0057] Step 1, paving the whole veneer 9 of bamboo bundles to be detected evenly on the feeding end of the feeding mechanism 3;

[0058] Step 2, set in the PC machine 1 the detection quantity, the stiffness detection pressure value, the initialization light intensity, the qualified density range and the qualified stiffness value range parameters for segmental detection of the density and rigidity of the whole veneer 9 of bamboo bundles;

[0059] Step 3, the first main control board 2 controls the density detection module to perform density detection, and at the same time the first main control board 2 controls the feeding mechanism 3 to continue to move forward, and the PC 1 reads and draws the whole veneer 9 along the bamboo bundle Light atten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com