Method for preparing instant high-fiber coconut powder by cold press coupling and low temperature pulverization

A technology of low-temperature crushing and coconut powder, which is applied in the direction of fat oil/fat production, fat production, food science, etc., can solve the problem of low oil yield, and achieve the effects of high safety, convenience for drinking, and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

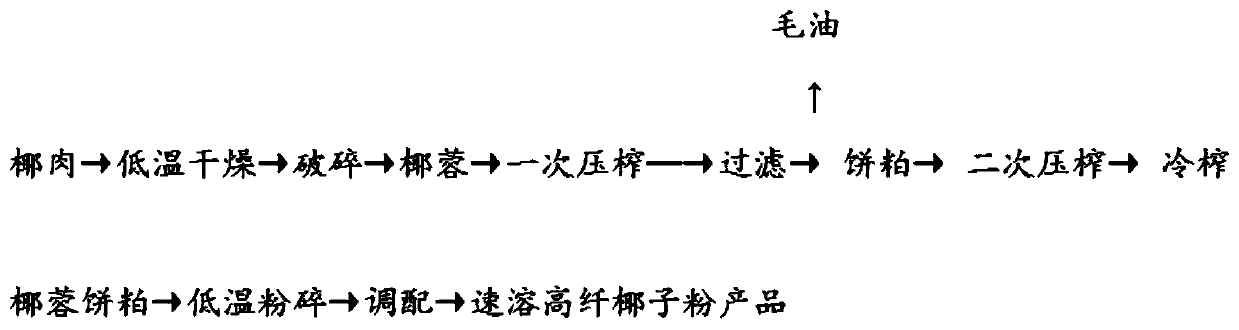

Method used

Image

Examples

Embodiment 1

[0038] A kind of method of cold pressing coupling low-temperature pulverization of the present embodiment prepares instant high-fiber coconut powder, described method comprises the following steps:

[0039] (1) Cleaning and slicing: the purpose of cleaning is to remove various impurities in the raw coconut meat, such as: iron, stones, soil blocks, etc., and the impurity content of the raw materials must not exceed 0.2%; Cut the sliced meat into 3-4mm coconut flakes;

[0040] (2) Drying: drying the coconut flakes obtained in step (1), adopting a low-temperature drying process to reduce the moisture to below 4%, and the raw material temperature must not be higher than 60°C in the drying process; the low-temperature drying process is to reduce the amount of protein transsexual;

[0041] (3) Broken, tempered: add water to step (2) drying gained coconut flakes, control the moisture content of coconut oil raw material to be 10%, under room temperature, coconut meat is broken, the...

Embodiment 2

[0048] A kind of method of cold pressing coupling low-temperature pulverization of the present embodiment prepares instant high-fiber coconut powder, described method comprises the following steps:

[0049] (1) Cleaning and slicing: the purpose of cleaning is to remove various impurities in the raw coconut meat, such as: iron, stones, soil blocks, etc., and the impurity content of the raw materials must not exceed 0.2%; Cut the sliced meat into 3-4mm coconut flakes;

[0050] (2) drying: the coconut flakes obtained in step (1) are dried, and the vacuum freeze-drying process (the charging height is 12mm, the heating plate temperature is 45°C, and the oven pressure is 40Pa) is used to reduce the moisture to below 4%, and dry The raw material temperature during the process shall not be higher than 60°C; the low-temperature drying process is to reduce protein denaturation;

[0051] (3) Broken, tempered: add water to step (2) oven dry gained coconut flakes, control the moisture c...

Embodiment 3

[0057] A kind of method of cold pressing coupling low-temperature pulverization of the present embodiment prepares instant high-fiber coconut powder, described method comprises the following steps:

[0058] (1) Cleaning and slicing: the purpose of cleaning is to remove various impurities in the raw coconut meat, such as: iron, stones, soil blocks, etc., and the impurity content of the raw materials must not exceed 0.2%; Cut the sliced meat into 3-4mm coconut flakes;

[0059] (2) Drying: drying the coconut flakes obtained in step (1), adopting a low-temperature drying process to reduce the moisture to below 4%, and the raw material temperature must not be higher than 60°C in the drying process; the low-temperature drying process is to reduce the amount of protein transsexual;

[0060] (3) Broken, tempered: add water to step (2) drying gained coconut flakes, control the moisture content of coconut oil raw material to be 10%, under room temperature, coconut meat is broken, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com