Preparation and control method of a catalytic electrode for bioelectrochemical and photocatalytic degradation of ethyl acetate and toluene gas

A bioelectrochemical and photoelectric catalysis technology, applied in physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve the problems of low quantum yield, high photoelectron-hole pair recombination rate, lack of visible light response, etc. Achieving the effect of good stability and remarkable purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

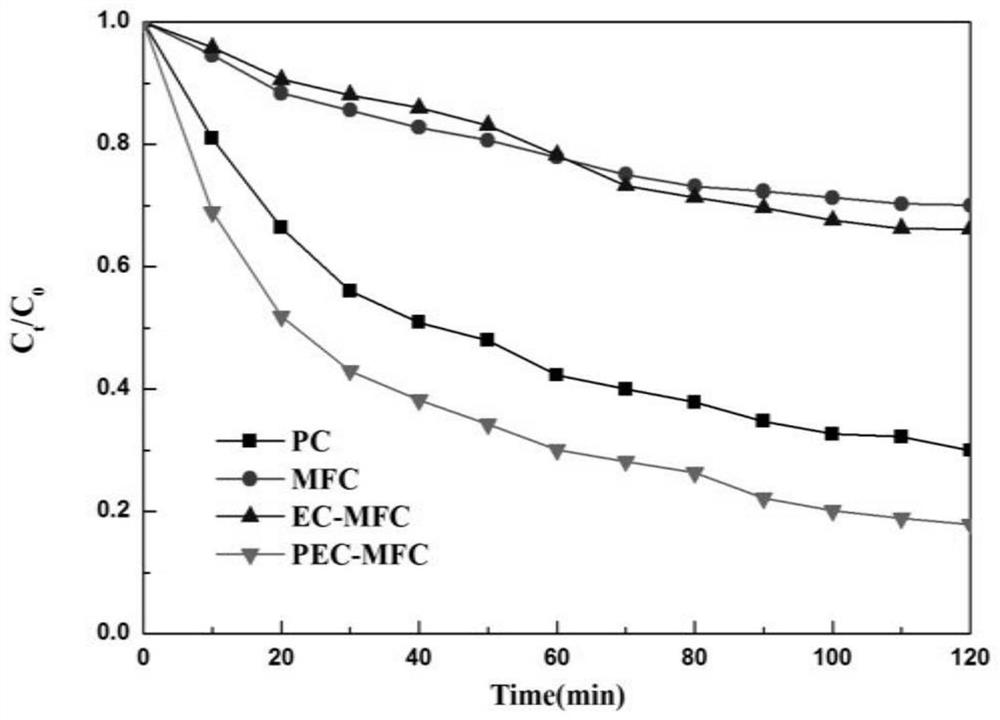

[0024] Example 1: Degradation of ethyl acetate gas under different systems

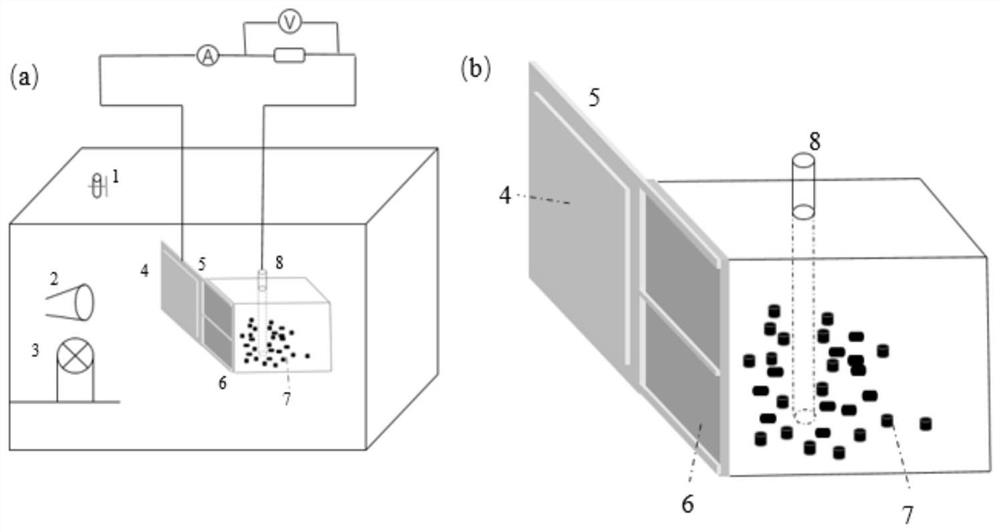

[0025] The interior of the reactor includes a 50w halogen tungsten lamp, a 3w small fan, and the volume of the anode chamber is 160cm 3 , equipped with Shewan's electrogenic bacteria and nutrient solution (52mL), the electrogenic bacteria are loaded on activated carbon (22g), the voltage is maintained between 0.35 and 0.4V, and the stainless steel mesh (3cm×6cm) loaded with 0.05g catalyst As the air cathode, microorganisms as the anode, separated by a proton exchange membrane in the middle, the electrons generated by the anode are exported from the copper wire through the carbon rod, the cathode is connected with the stainless steel mesh with the crocodile clip, and communicated with the external circuit through the copper wire, and the external circuit is connected with a resistor and ammeter voltmeter.

[0026] Before the reaction, use a 10 μL liquid-phase sampling needle to inject 2 μL ethyl aceta...

Embodiment 2

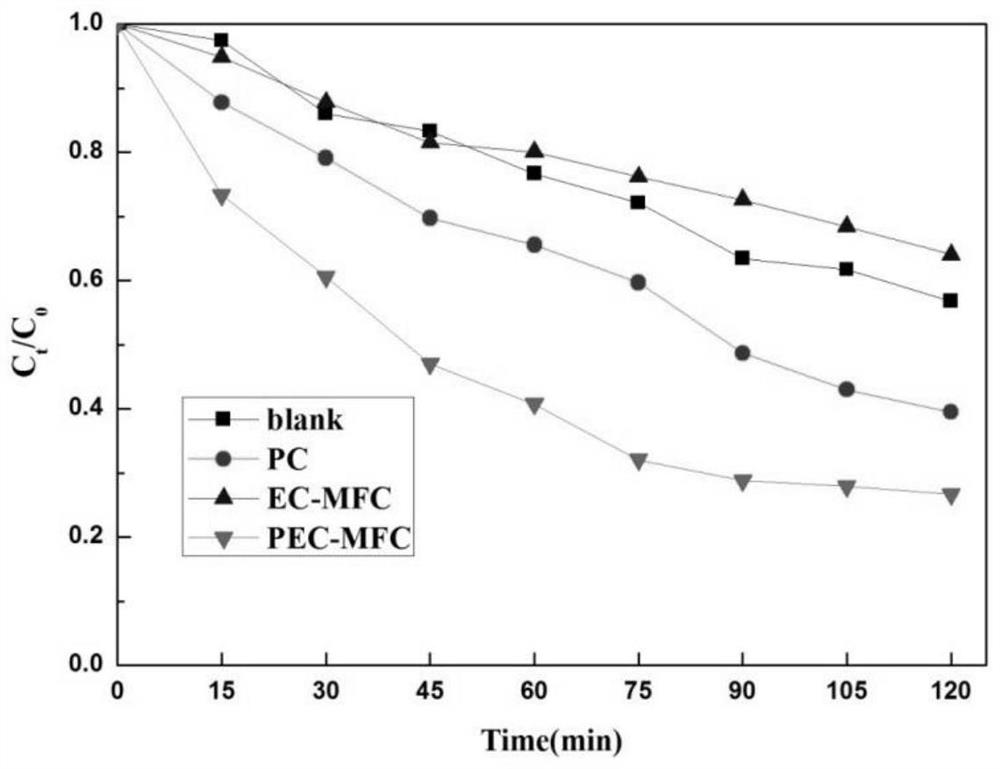

[0032] Embodiment two: Degradation of toluene gas under different systems

[0033] The reactor device is the same as in Example 1. Before the reaction, inject 4 μL of toluene solution (corresponding to a gas concentration of 340 ppm) into the reactor with a 10 μL liquid-phase sampling needle, and turn on the fan to mix evenly. After 30 minutes, start to connect the circuit and light for the reaction , the light source is facing the catalyst, and the distance from the catalyst is 5cm. Use a 1mL gas phase sampling needle to take samples. The measured concentration is recorded as the initial concentration C 0 , and then take a sample every 10 minutes, and record the data C t , The reaction time is 2h.

[0034] Blank control system: there is a stainless steel mesh (3cm×6cm) coated with 0.05g of material in the reactor, without MFC components, and the measurement is carried out without light;

[0035] PC system: the reaction device is similar to the blank control, the difference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com