Waste plastic bottle sorting system and sorting method thereof

A sorting system and technology for plastic bottles, applied in the field of waste recycling, can solve the problems of high production and processing costs, feedback, and sorting accuracy less than 80%, and achieve the effect of reasonable structure and layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

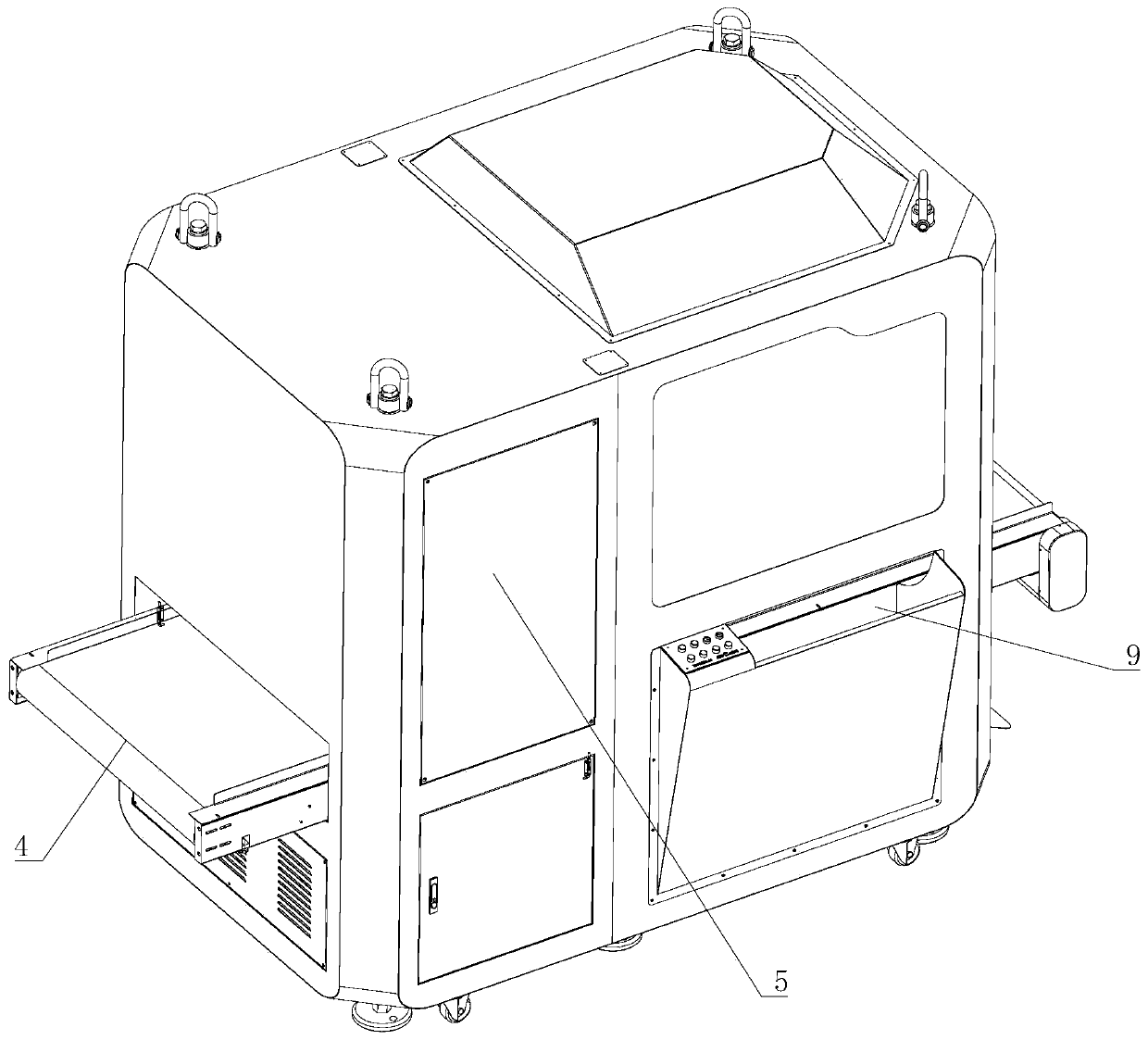

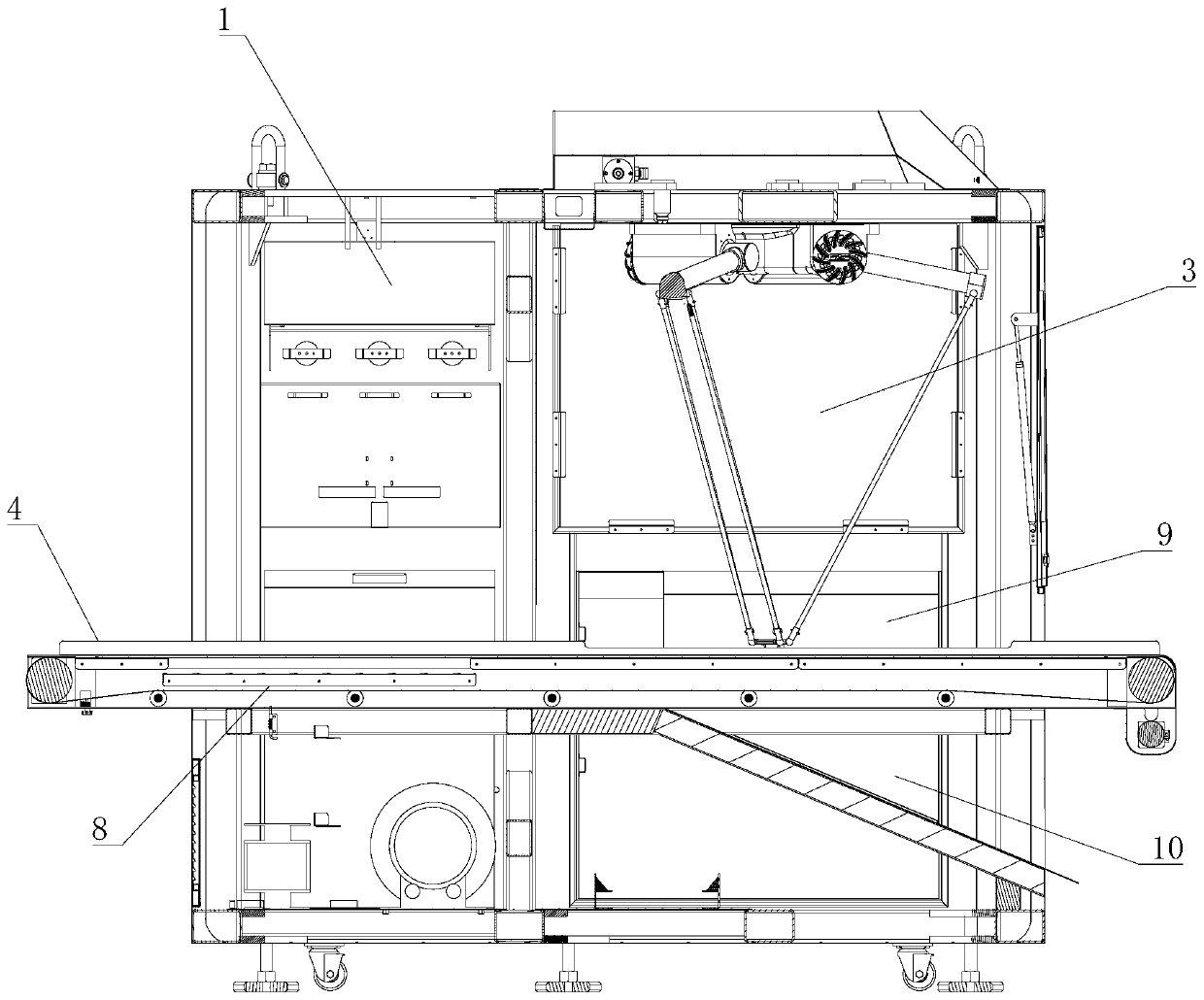

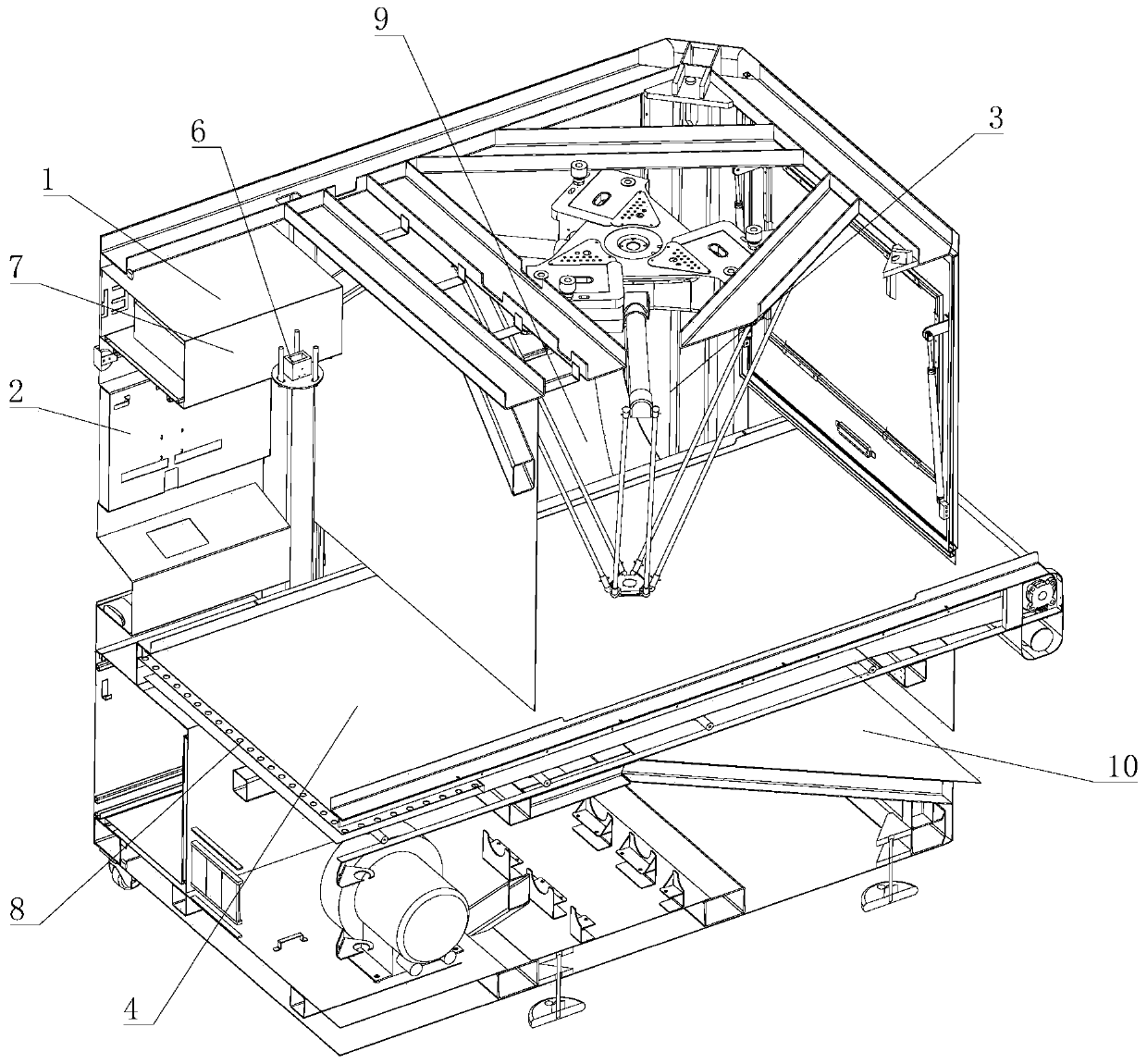

[0036] like Figure 1 to Figure 3As shown, the waste plastic bottle sorting system includes a detection unit 1, a system control unit 2, a mechanical sorting unit 3, a conveying unit 4, and a safety shield 5, and the conveying unit 4 sequentially sends waste plastic bottles into the detection unit 1. The mechanical sorting unit 3, the system control unit 2 is respectively connected with the detection unit 1, the mechanical sorting unit 3, and the conveying unit 4; the detection unit 1 includes a visual detection module 6, a material detection module 7, a light source 8; the visual detection module 6 is based on the principle of camera imaging, and collects color information, shape information, and position information on the waste plastic bottles on the conveying unit 4; the material detection module 7 is based on an infrared online detection method. The waste plastic bottles on the conveying unit 4 carry out material analysis and collect material information; the system contr...

Embodiment 2

[0038] The difference from Embodiment 1 is that the mechanical sorting unit 3 is composed of a plurality of parallel robots, and the system control unit 2 calculates the most reasonable optimized motion trajectory through motion path simulation and the simulated motion The trajectory and collaborative tasks are sent to each parallel robot in real time, and the data is optimized and updated in real time to ensure that multiple parallel robots work together to achieve the highest sorting efficiency.

Embodiment 3

[0040] The sorting method of the waste plastic bottle sorting system, the specific steps are as follows:

[0041] 1S. Spread the pretreated bottle on the conveying unit 4 and send it to the detection unit 1;

[0042] 2S. The visual detection module 6 in the detection unit 1 visually photographs the waste plastic bottles on the detection unit 1 through camera imaging, and collects preliminary position information, shape information, and color information; Image 6 As shown, through the visual algorithm software combined with the gain adjustment of the brightness of the light source 8, the acquired image is preliminarily filtered, and the color type and color value of the bottle are determined through color value analysis and data comparison, and the final color data is output; at the same time, according to the waste product The image state of the plastic bottle calculates the outline information of the bottle and the position center coordinate point. The visual detection modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com