Wastewater treatment system and treatment method based on boron-doped diamond film

A sewage treatment system, diamond membrane technology, applied in water/sewage treatment, biological water/sewage treatment, flotation water/sewage treatment, etc. Green environmental protection and efficient advanced sewage treatment, improve operability, and avoid the effect of chemical injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

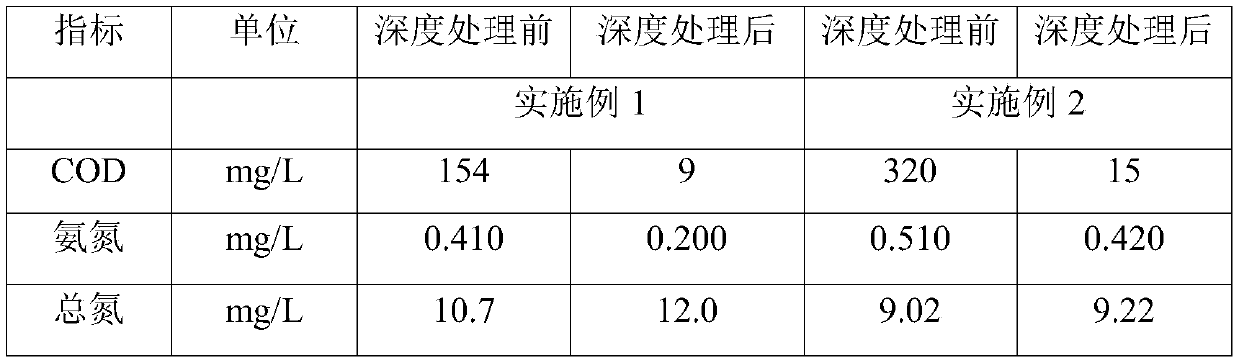

Embodiment 1

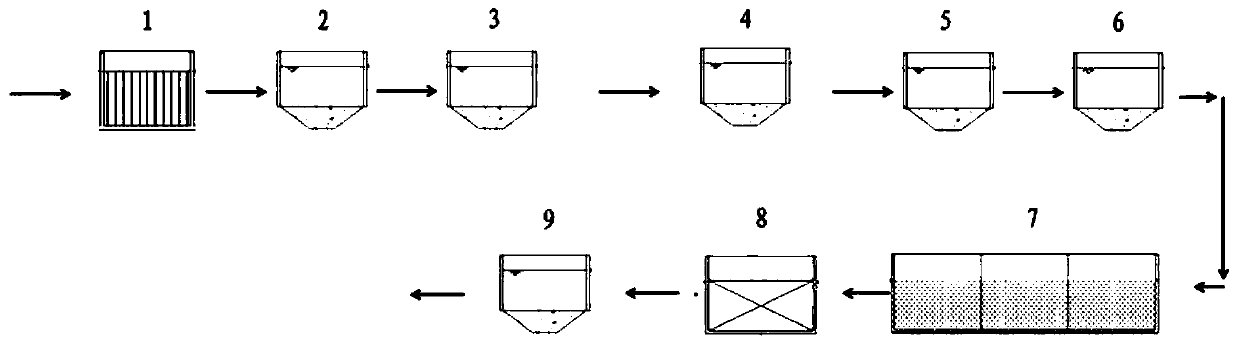

[0027] Such as figure 1 The sewage treatment system based on the boron-doped diamond film shown includes a thick and thin grid tank, an aeration tank, a primary sedimentation tank, a boron-doped diamond film pretreatment tank, an acid-base adjustment tank, and a secondary sedimentation tank connected sequentially by pipelines. , membrane bioreactor, hollow fiber ultrafiltration tank, boron-doped diamond film advanced treatment tank, boron-doped diamond film pretreatment tank and boron-doped diamond film advanced treatment tank use boron-doped diamond film as the anode.

[0028] The anode area in the boron-doped diamond film pretreatment pool is 0.5m 2 , the electrode spacing is 2mm, the current density is 0.2Acm -2 , the operating temperature of the system is 30°C. The effluent COD is 150mg / L.

[0029] The flocculant used in the primary settling tank is polyferric sulfate. First, the polyferric sulfate is made into a solution with a mass fraction of 10-30%, and then 30-50g ...

Embodiment 2

[0032] Such as figure 1 The sewage treatment system based on the boron-doped diamond film shown includes a thick and thin grid tank, an aeration tank, a primary sedimentation tank, a boron-doped diamond film pretreatment tank, an acid-base adjustment tank, and a secondary sedimentation tank connected sequentially by pipelines. , membrane bioreactor, hollow fiber ultrafiltration tank, boron-doped diamond film advanced treatment tank, boron-doped diamond film pretreatment tank and boron-doped diamond film advanced treatment tank use boron-doped diamond film as the anode.

[0033] The anode area in the boron-doped diamond film pretreatment pool is 1m 2 , the electrode spacing is 5mm, the current density is 0.2Acm -2 , the operating temperature of the system is 32°C. The effluent COD is 500mg / L.

[0034] The flocculant used in the primary settling tank is polyferric sulfate. First, the polyferric sulfate is made into a solution with a mass fraction of 10-30%, and then 30-50g of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com