Degradable multinuclear chelated fertilizer and preparation method thereof

A multi-nuclear, iminodisuccinate technology, applied in the field of degradable multi-nuclear chelated fertilizer and its preparation, can solve the problems of restricting the popularization and application of green and environmentally friendly chelated fertilizers, limited leaf surface adsorption, and the inability to metal ions, etc., to achieve high greenness Environmentally friendly use value, improved surface tension, enhanced adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] After each raw material is weighed according to mass fraction in this embodiment 1, the mass ratio after conversion into percentage is as follows:

[0035] components Proportion(%) IDS 46 citric acid 11 Mannitol 2 Manganese Sulfate Monohydrate 9 Zinc Sulfate Monohydrate 23 Anhydrous copper sulfate 8 KOH 1

[0036] Prepare as follows:

[0037] S10, add the above IDS, citric acid, and mannitol into the reaction kettle, stir at room temperature for 10 minutes, and rotate at a speed of 15 Hz;

[0038] S20, adding KOH, adjusting the pH value to 5.0, forming an acid-base environment for the chelation reaction;

[0039] S30, add the above manganese sulfate monohydrate, zinc sulfate monohydrate, and copper sulfate anhydrous into the reaction kettle, raise the reaction temperature to 80°C, adjust the speed to 30Hz, keep stirring for 1 hour, if there is no dissolution or agglomeration, reduce the temperature Adjust to 90...

Embodiment 2

[0041] After each raw material is weighed according to mass fraction in this embodiment 2, the mass ratio after conversion into percentage is as follows:

[0042] components Proportion(%) IDS 45 citric acid 13 Sorbitol 2.5 Manganese Sulfate Monohydrate 8 Zinc Sulfate Monohydrate 22.5 Calcium acetate monohydrate 7 KOH 2

[0043] S10, add the above IDS, citric acid, and sorbitol into the reaction kettle, stir at room temperature for 10 minutes, and rotate at 20 Hz;

[0044] S20, adding KOH, adjusting the pH value to 5.5, forming an acid-base environment for the chelation reaction;

[0045] S30, add the above manganese sulfate monohydrate, zinc sulfate monohydrate, and calcium acetate monohydrate into the reaction kettle, raise the reaction temperature to 75°C, adjust the speed to 35Hz, keep stirring for 1 hour, if there is no dissolution or agglomeration, adjust the temperature To 90°C, keep the rotation speed at 35Hz, h...

Embodiment 3

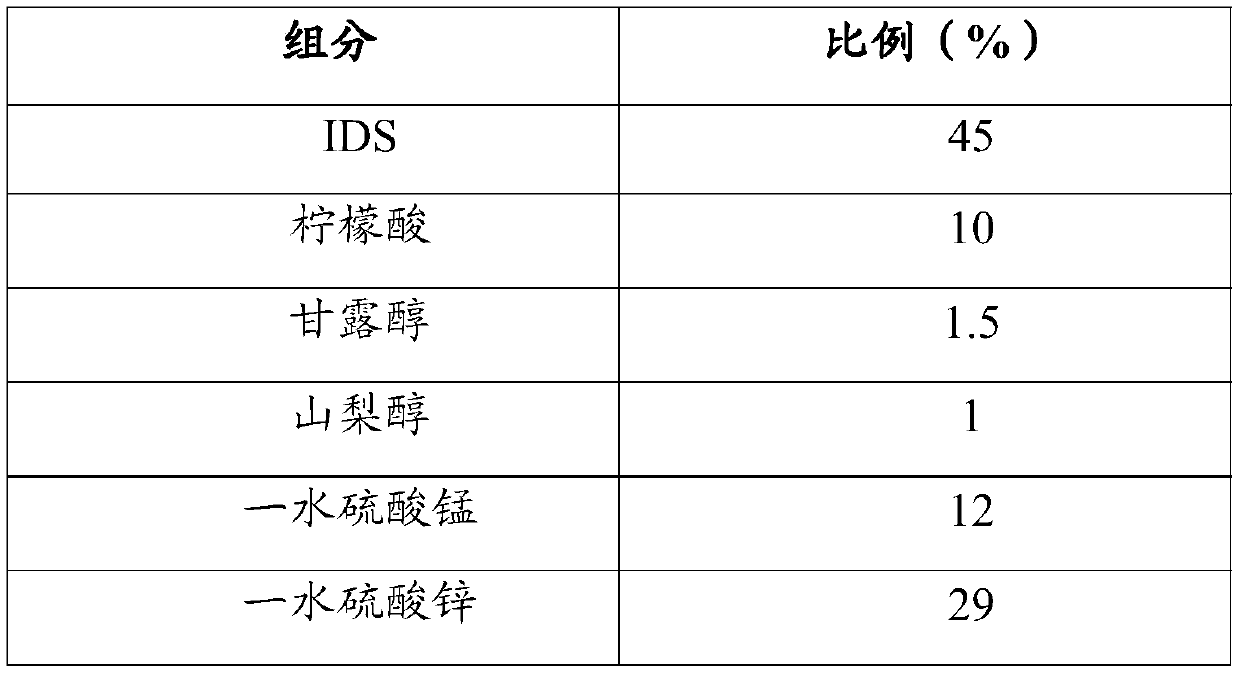

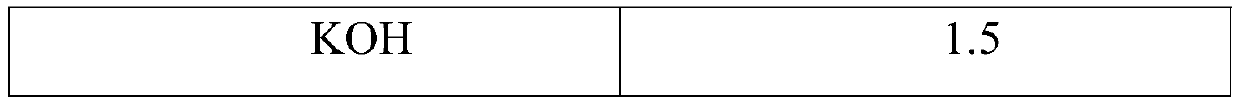

[0047] After each raw material is weighed according to mass fraction in this embodiment 3, the mass ratio after conversion into percentage is as follows:

[0048]

[0049]

[0050] S10, add the above IDS, citric acid, and sorbitol into the reaction kettle, stir at room temperature for 10 minutes, and rotate at 20 Hz;

[0051] S20, adding KOH, adjusting the pH value to 5.5, forming an acid-base environment for the chelation reaction;

[0052] S30, add the above manganese sulfate monohydrate, zinc sulfate monohydrate, and calcium acetate monohydrate into the reaction kettle, raise the reaction temperature to 85°C, adjust the speed to 35Hz, keep stirring for 1.5h, if there is no dissolution or agglomeration, the temperature Adjust to 95°C, keep the rotation speed at 35Hz, keep stirring for 45min, and obtain degradable multi-nuclear chelate fertilizer after cooling at room temperature.

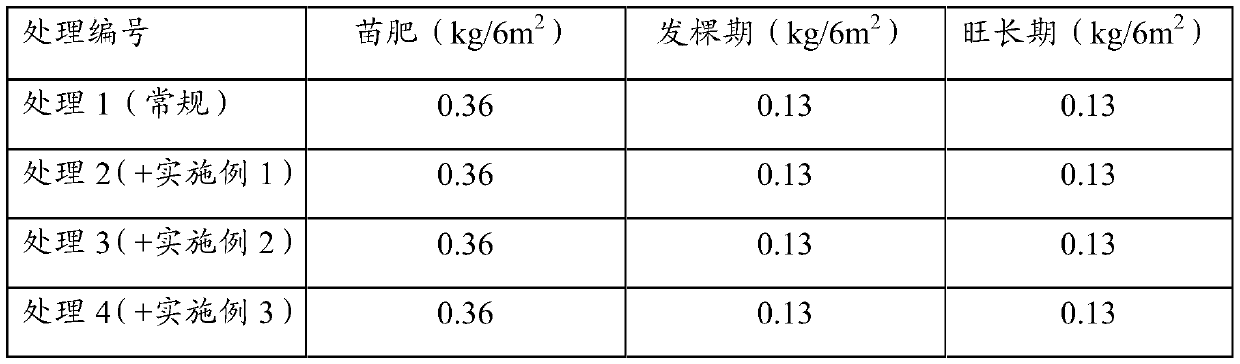

[0053] The fertilizer prepared by each of the above embodiments further illustrates the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com