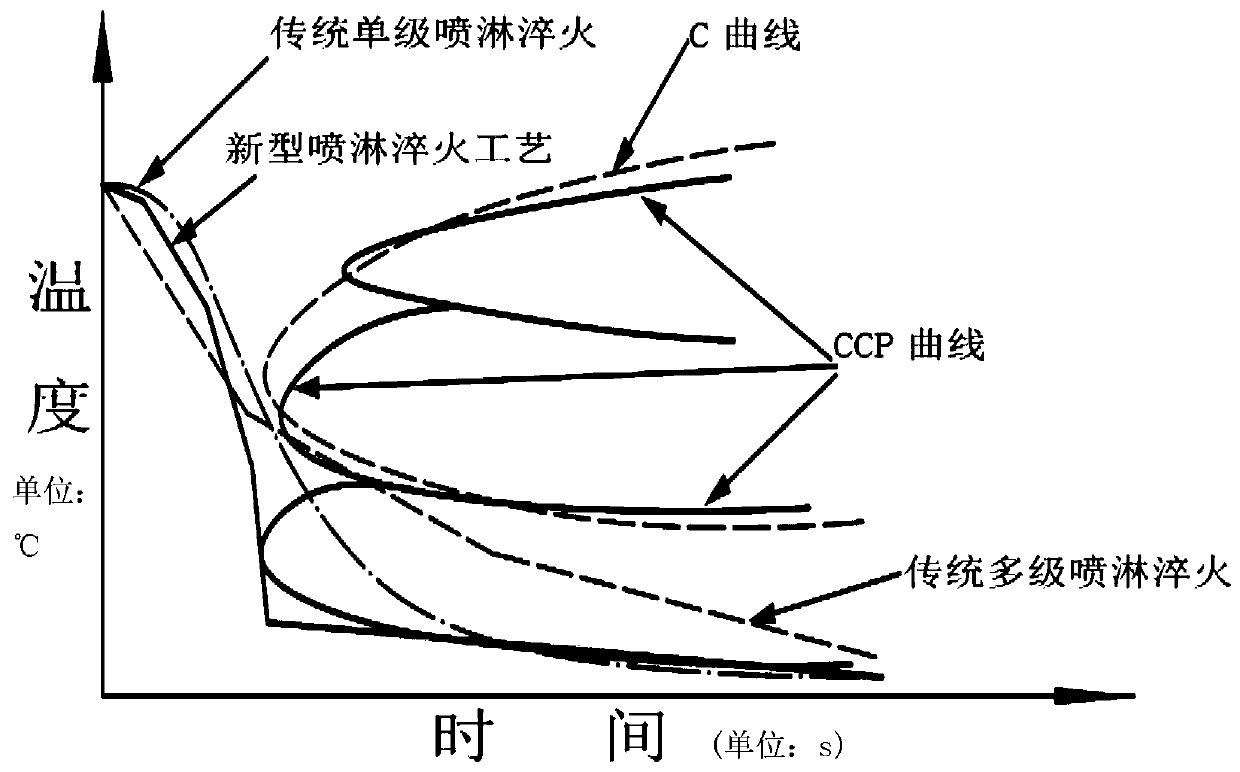

Novel sprinkling quenching process applied to aluminum alloy plate

A technology of aluminum alloy plates and aluminum alloy materials, which is applied in the field of new spray quenching technology, can solve problems such as hindering the production of aluminum thick plates by spray cooling, large residual stress, etc., and achieve the effect of promoting high-quality production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] AA7150 aluminum alloy (solution temperature: 480°C) is spray-quenched, and the plate thickness is 80 mm. There are three precipitation reaction stages in this material, which are P 1 Stage (455°C, 350°C) minimum critical cooling rate CR 1 is 10℃ / s, P 2 Stage (350°C, 255°C) minimum critical cooling rate CR 2 is 80℃ / s, P 3 Stage (255°C, 150°C) minimum critical cooling rate CR 3 300°C / s;

[0036] Therefore, the cooling curve of the aluminum thick plate is designed to be 5 sections, that is, Q 0 Stage (480°C, 455°C) cooling rate is air cooling rate CR air , Q 1 , Q 2 , Q 3 The temperature ranges of the stages are (455°C, 350°C), (350°C, 255°C), (255°C, 150°C), Q 1 The stage cooling rate is 10°C / s, Q 2 The stage cooling rate is 80°C / s, Q 3 The stage cooling rate is 300°C / s, Q 4 Stage (150°C, room temperature) cooling rate is air cooling rate CR air ;

[0037] When industrial tap water at 20°C is used as the cooling medium, there will be no water spray from the ...

Embodiment 2

[0039] AA2618 aluminum alloy (solution temperature: 530°C) plate is quenched, with a plate thickness of 80mm. There are two precipitation reaction stages in this material, which are P 1 Stage (390°C, 280°C) minimum critical cooling rate CR 1 is 20℃ / s, P 2 Stage (280°C, 170°C) minimum critical cooling rate CR 2 100°C / s;

[0040] Therefore, the cooling curve of the aluminum thick plate is designed into 4 sections, that is, Q 0 Stage (530°C, 390°C) cooling rate is air cooling rate CR air , Q 1 , Q 2 The temperature ranges of the stages are (390°C, 280°C), (280°C, 170°C), Q 1 The stage cooling rate is 20°C / s, Q 2 The stage cooling rate is 100°C / s, Q 3 Stage (170°C, room temperature) cooling rate is air cooling rate CR air ;

[0041] When industrial tap water at 20°C is used as the cooling medium, there is no water spraying from the nozzle at 0-14s, no water spraying at the nozzle and forced convection air cooling is used at 14s-19.5s, and the nozzle pressure is 100kPa at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com