Conductive framework and preparation method thereof

A skeleton, nickel foam technology, applied in the field of energy storage, can solve the problems of high negative electrode reactivity, consumption of lithium source, increase of internal resistance and internal consumption of battery, etc., to improve lithophilicity and specific surface area, prolong storage life, slow down The effect of volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

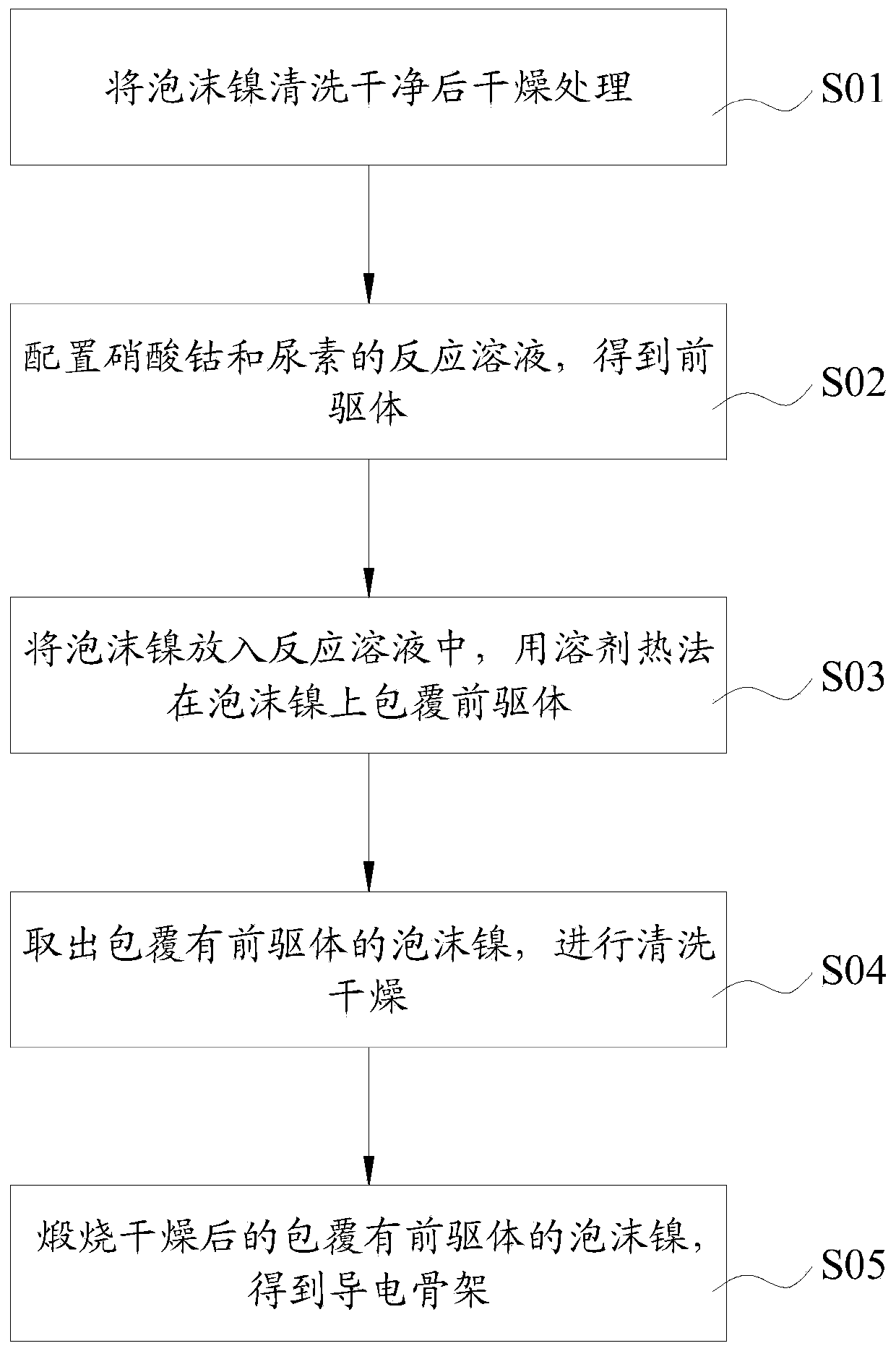

[0038] figure 1 It is a flow chart of the preparation method of the conductive framework of the present invention, such as figure 1 As shown, the preparation method of the conductive framework of the present embodiment comprises the following steps:

[0039] S01, dry the nickel foam after cleaning;

[0040] In step S01 of this embodiment, a piece of regular nickel foam (NF) is selected first, and then the nickel foam is cleaned and then dried. The cleaning process specifically includes: sequentially immersing the nickel foam in acetone, ethanol, hydrochloric acid, and deionized water for ultrasonic cleaning. The ultrasonic cleaning time is 15 minutes; Drying is carried out in the furnace, and after the drying is completed, a spare clean foamed nickel sheet can be obtained.

[0041] S02, configuring a reaction solution of cobalt nitrate and urea to obtain a precursor;

[0042] In step S02 of this embodiment, it is necessary to use the dried nickel foam as a substrate to pre...

Embodiment 2

[0053] As another embodiment of this description, different from Example 1, in step S01 of this embodiment, a piece of regular foamed nickel (NF) is first selected, the thickness of foamed nickel is 1mm, and the size of foamed nickel is 2.5 mm. ×5cm, on the basis of this embodiment, the thickness and size of the nickel foam can be selected according to the size of the battery to be assembled in actual production.

[0054] In step S02 of this embodiment, the molar ratio of cobalt nitrate and urea is 1:2, the volume ratio of methanol and ethanol is 1:1, and the magnetic stirring time is 30 min. On the basis of this example, the molar ratio of cobalt nitrate to urea, the volume ratio of methanol to ethanol and the time of magnetic stirring can be selected in actual production.

[0055] In step S03 of this embodiment, the reaction time in the oven is 12h.

[0056] In step S05 of this embodiment, the dried nickel foam coated with the precursor is placed in a tube furnace to heat up ...

Embodiment 3

[0059] As yet another embodiment of this specification, different from Example 2, in step S03 of this example, the nickel foam coated with cobalt tetraoxide nanosheets obtained after the reaction time in the oven is 8h, wherein the cobalt tetraoxide nanosheets It is looser than the cobalt tetraoxide nanosheets in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com