Compound type high-efficiency spraying agent and application thereof

A spray and compound technology, applied in the field of pesticides, can solve the problems of difficult to eliminate microbial hazards, difficult processing, short duration of effect, etc., and achieve the effects of inhibiting the growth of fungi and bacteria, excellent resistance to hard water, and excellent dispersion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

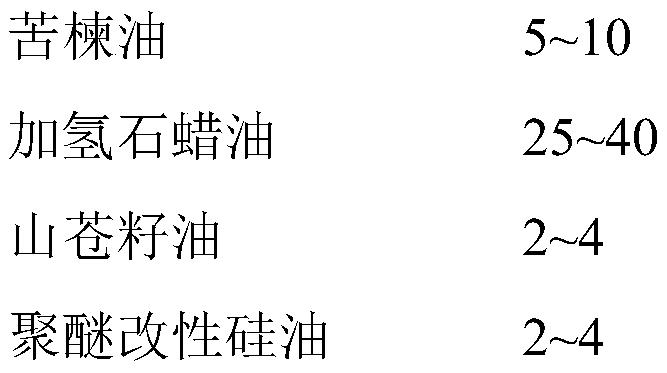

[0026] In this example, in the process of preparing the composite high-efficiency spray agent, 25 parts of hydrogenated paraffin oil were weighed, and then 2 parts of polyether modified silicone oil were added, and the stirring was started. While stirring, 5 parts of neem oil and 2 parts of neem oil were added Litsea cubeba seed oil, and then continue to stir for 20 minutes to obtain the finished compound high-efficiency spraying agent.

[0027] Using the developed compound high-efficiency spray agent, a large-scale evaluation of phytotoxicity against spider mite damage was carried out. Mix the required amount per kilogram of spray with 10 liters of water and spray the resulting emulsion over the tea bushes with a hand-held sprayer. where the result is as follows:

[0028]

[0029] The toxicity test result shows that the composite high-efficiency spray agent in this example has no phytotoxicity to tea trees.

Embodiment 2

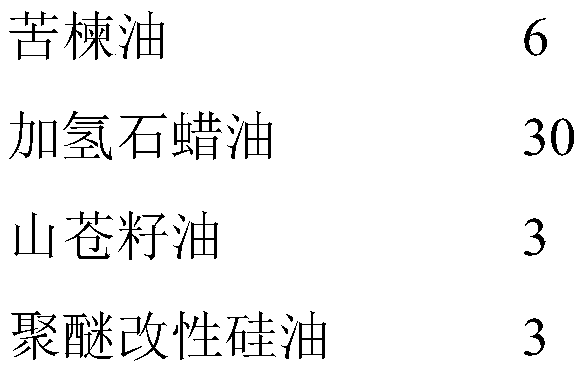

[0031] In this embodiment, during the preparation of the composite high-efficiency spray agent, 30 parts of hydrogenated paraffin oil were weighed, and then 3 parts of polyether modified silicone oil were added, and the stirring was started. While stirring, 6 parts of neem oil and 3 parts of neem oil were added Litsea cubeba seed oil, and then continued to stir for 20 minutes to obtain the finished compound high-efficiency spraying agent.

[0032] Using the developed agricultural spray oil, a large-scale evaluation of phytotoxicity and infection tests against red spider damage was carried out. Mix the required amount per kilogram of spray oil with 10 liters of water, and spray the resulting emulsion on the tea bushes with a hand-held sprayer. As can be seen from the treatment results, the metered spray agent basically eliminated the existence of red spiders, and reached the best deworming effect in the test targets of the three groups of tea trees. Toxicity test result is tha...

Embodiment 3

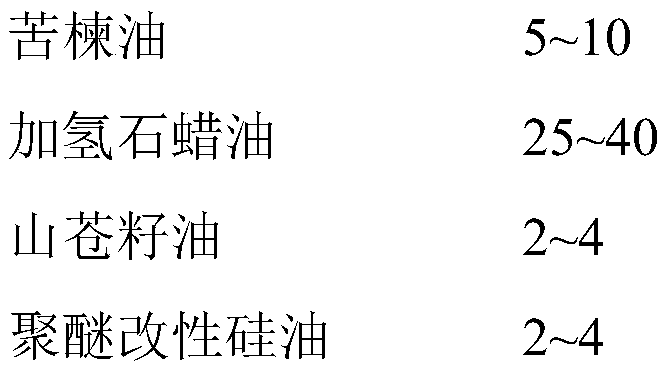

[0034] In this embodiment, during the preparation of the composite high-efficiency spray agent, 30 parts of hydrogenated paraffin oil were weighed, and then 4 parts of polyether modified silicone oil were added, and the stirring was started. While stirring, 10 parts of neem oil and 4 parts of neem oil were added Litsea cubeba seed oil, and then continued to stir for 20 minutes to obtain the finished compound high-efficiency spraying agent.

[0035] Using the developed agricultural spray oil, a large-scale evaluation of phytotoxicity and infection tests against red spider damage was carried out. Mix the required amount per kilogram of spray oil with 10 liters of water, and spray the resulting emulsion on the tea bushes with a hand-held sprayer. It can be seen from the treatment results that the metered spray substantially eliminated the presence of spider mite. Toxicity test result is that the composite type high-efficiency spray agent in the present embodiment has no phytotox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com