Device and method for continuously preparing polyaniline nanofiber through mobile interface polymerization

A nanofiber, mobile interface technology, applied in chemical instruments and methods, fiber chemical characteristics, single-component synthetic polymer rayon, etc., can solve the problem of difficult to achieve large-scale continuous production, limited synthesis efficiency, and limited yield problems such as interface area, to achieve the effect of improving synthesis efficiency, improving monomer utilization, and avoiding post-processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

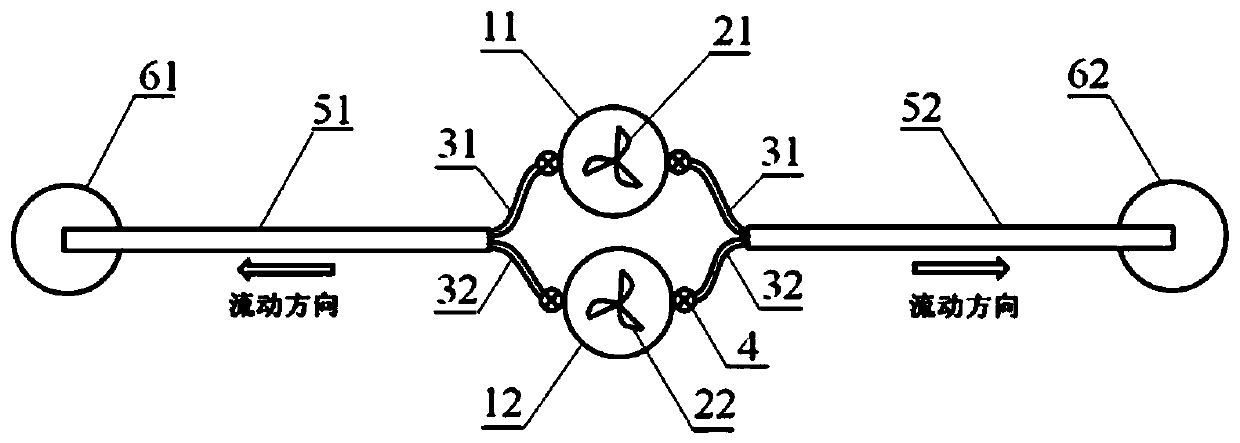

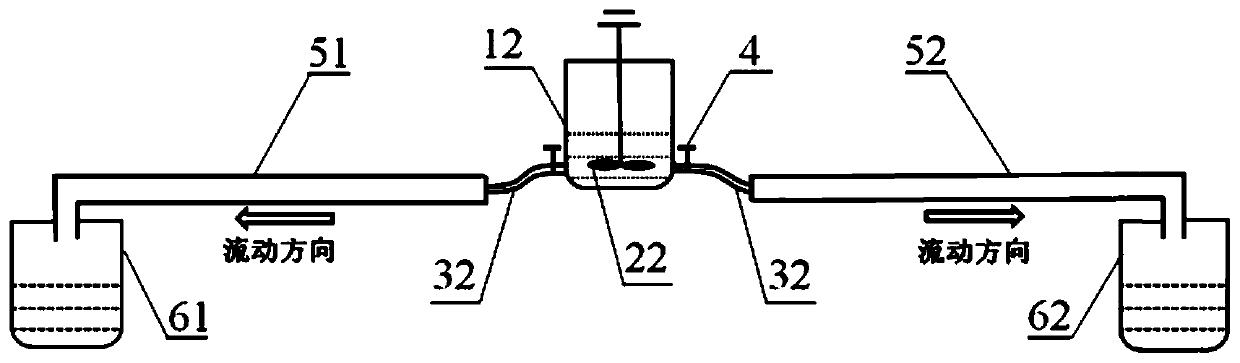

[0040] Such as figure 1 with 2 As shown, the device for continuously preparing polyaniline nanofibers by moving interfacial polymerization in this embodiment includes a first container 11 and a second container 12, the first container 11 is provided with a first stirring device 21, and the second container 12 is provided with The second stirring device 22 uses the stirring device to mix the solution in the container uniformly and provide it with flow driving force. The bottom of the first container 11 is communicated with the feed end of the reaction tube through the first connection pipe 31, the bottom of the second container 12 is communicated with the feed end of the reaction tube through the second connection pipe 32, and the discharge end of the reaction tube is communicated with the collection container , the first connecting pipe 31 and the second connecting pipe 32 are provided with a valve 4 .

[0041] Preferably, in this embodiment, the number of first connecting t...

Embodiment 2

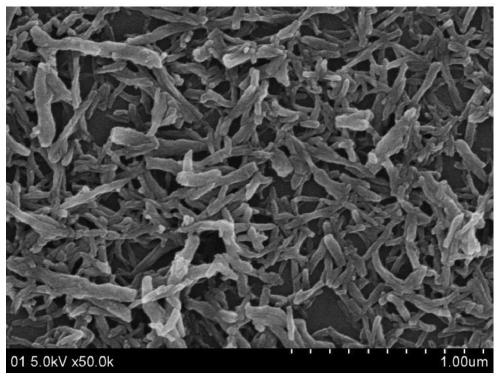

[0048] The internal diameter of the first container 11 and the second container 12 in the device for continuously preparing polyaniline nanofibers by moving interface polymerization of the present embodiment is 50.2 mm, and the diameter of the first stirring device and the second stirring device is 50.0 mm; The length of the tube is 5.0m, and the inner diameter is 8.0mm; other implementations are the same as in Example 1.

[0049] The preparation method of the polyaniline nanofiber of the present embodiment is as follows:

[0050] (1) Accurately weigh 372.5g aniline monomer and 650.0g ferric trichloride, join the aniline monomer into the first container containing xylene, join ferric chloride into the container containing 0.5mol / L doped In the second container of acid solution, wherein mixed dopant is made up of phosphoric acid and perchloric acid, the molar ratio of phosphoric acid and perchloric acid is 1:2;

[0051] (2) Set the speed of the organic phase stirring device to...

Embodiment 3

[0054] The internal diameter of the first container 11 and the second container 12 in the device for continuously preparing polyaniline nanofibers by moving interface polymerization of the present embodiment is 100.0 mm, and the diameter of the first stirring device and the second stirring device is 95.0 mm; the reaction The length of the pipe is 10.0m, and the inner diameter is 15.0mm; other implementations are the same as in Example 1.

[0055] The preparation method of the polyaniline nanofiber of the present embodiment is as follows:

[0056] (1) Accurately weigh 46.6g of aniline monomer and 1210.0g of benzoyl peroxide, add the aniline monomer into the first container filled with chloroform, and add benzoyl peroxide into the container filled with 1mol / L sulfuric acid solution in the second container of

[0057] (2) Set the rotation speed of the organic phase stirring device to 1000r / min (the rotation speed ratio of the organic phase and the water phase is 1:2), and after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com