Curing stabilizing agent for treating heavy-metal-containing waste residues and curing method thereof

A technology of stabilizer and heavy metal, applied in the treatment of solidification stabilizer containing heavy metal waste residue and its solidification field, can solve the problems of lack of extraction and recovery methods, low metal content, large difference in morphology, etc., and achieve faster adsorption equilibrium speed and large specific surface area. , the effect of developed pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The curing stabilizer in the present embodiment comprises the following components in parts by weight:

[0026] Stabilizer methylenebisacrylamide-sodium dimethyldithiocarbamate composite material 25 parts;

[0027] Adsorbent-loaded iron acid-base modified biochar 35 parts;

[0028] 40 parts of curing agent inorganic cementitious material, including 30 parts of cement and 10 parts of lime.

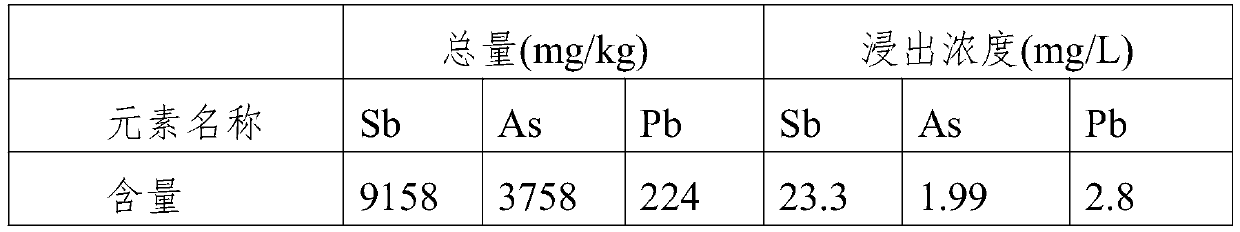

[0029] Taking the waste residue left by an antimony smelter in Xinshao, Hunan Province as the solidification object, the composition of the main harmful elements of the waste residue is shown in Table 1.

[0030] Table 1 Composition of main harmful elements in waste residue left over from an antimony smelter in Xinshao, Hunan

[0031]

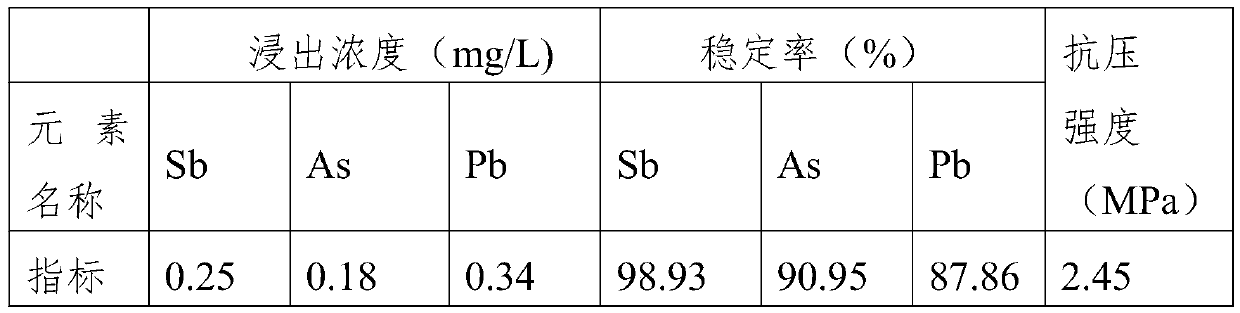

[0032] The solidification method of using the solidification stabilizer of this embodiment to treat waste slag containing heavy metals is: mix the waste slag left over from a certain antimony smelter in Xinshao, Hunan Province with the solidifica...

Embodiment 2

[0038] The curing stabilizer in the present embodiment comprises the following components in parts by weight:

[0039] 30 parts of stabilizer methylenebisacrylamide-sodium dimethyldithiocarbamate composite material;

[0040] 30 parts of adsorbent-loaded iron acid-base modified biochar;

[0041] Portland cement 40 parts.

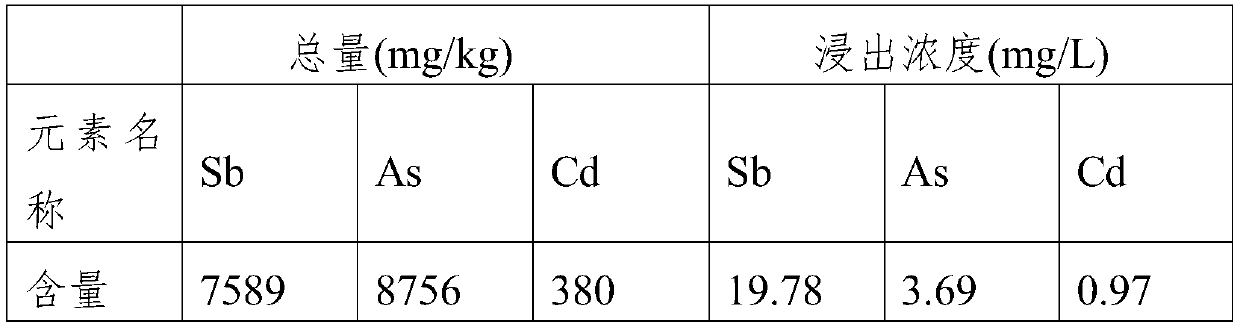

[0042] Taking the waste residue of an antimony smelter in Lengshuijiang, Hunan Province as the solidification object, the composition of the main harmful elements of the waste residue is shown in Table 3.

[0043] Table 3 Composition of main harmful elements in the waste residue of an antimony smelter in Lengshuijiang, Hunan

[0044]

[0045] The solidification method of using the solidification stabilizer of this embodiment to treat waste residue containing heavy metals is: mix the waste residue of a certain antimony smelter in Lengshuijiang, Hunan Province with the solidification stabilizer, the mass ratio of the waste residue to the above solidificati...

Embodiment 3

[0051] The curing stabilizer in the present embodiment comprises the following components in parts by weight:

[0052] 10 parts of stabilizer methylenebisacrylamide-sodium dimethyldithiocarbamate compound;

[0053] 30 parts of adsorbent-loaded iron acid-base modified biochar;

[0054] 60 parts of curing agent inorganic cementitious material, including 50 parts of cement and 10 parts of gypsum.

[0055] Taking the waste slag left over from an antimony smelter in Jiangxi as the solidification object, the composition of the main harmful elements of the waste slag is shown in Table 5.

[0056] Table 5 Composition of main harmful elements in waste residue left over from an antimony smelter in Jiangxi

[0057]

[0058] The solidification method of using the solidification stabilizer of this embodiment to treat waste residue containing heavy metals is: mix the waste residue left over from a certain antimony smelter in Jiangxi with the solidification stabilizer, the mass ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com