Three-stage rotating disc-type sewage treatment device based on biologically active filler

A sewage treatment device and biologically active technology, which is applied in the field of three-stage turntable sewage treatment equipment, can solve the problems of insufficient nitrogen removal organic matter, sludge loss, and poor biological phosphorus removal effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

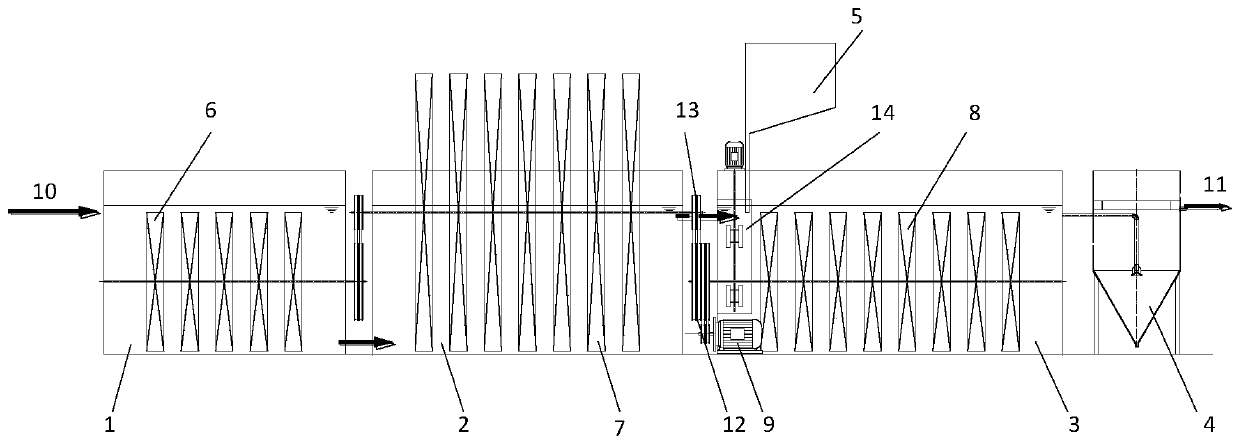

[0024] For urban sewage treatment, the parameters are set for the three-stage turntable sewage treatment process technology process based on biologically active fillers. For specific device connections, see the attached figure 1 . The structural form of the three units is a disc cage structure, and the cage is filled with biologically active fillers to form cage-type biological turntables with different performances. These turntables are driven by the drive system to rotate in their respective reaction pools, and the aerobic pool (Nitrification tank) half of the nitrification biological turntable is submerged in water and half is exposed to the air. Oxygenation and water stirring are realized by rotation. The turntables in the denitrification tank and anaerobic hydrolysis tank are all submerged in water, and the rotation is realized by rotation. Stir in water.

[0025] The water flow rate of the treatment device is 0.8m 3 / h;

[0026] Anaerobic hydrolysis and acidification ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com