Strain SH-1 producing alginate lyase and application thereof

A technology of alginate lyase and bacterial strain, applied in the direction of lyase, application, bacteria, etc., can solve the problems of low enzyme activity, limiting the development of seaweed extract, single degradation site, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

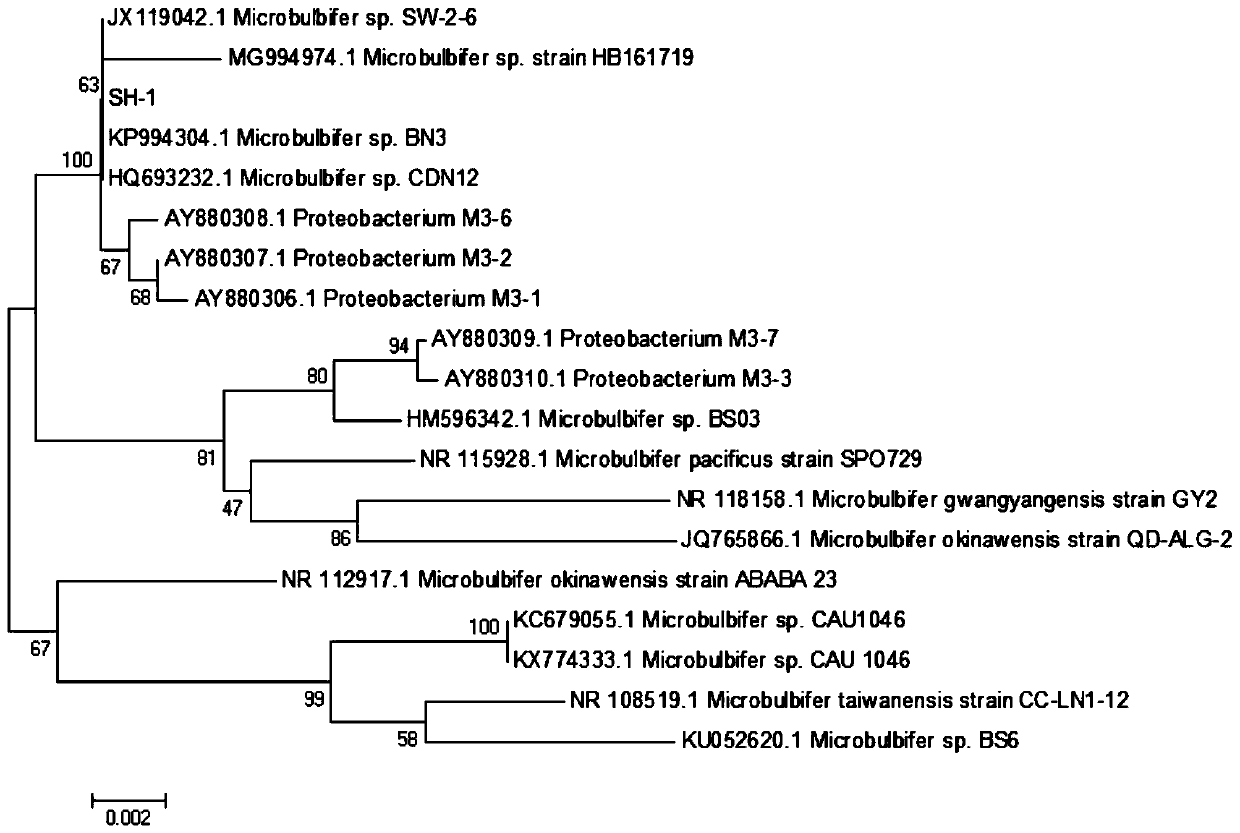

[0088] Example 1 Isolation, screening and identification of Microbulbifer sp.SH-1

[0089] 1. Preparation of culture medium

[0090] (1) Enrichment medium: sodium alginate 5g / L, peptone 1g / L, NaCl 15g / L, (NH 4 ) 2 SO 4 5g / L, K 2 HPO 4 1g / L, MgSO 4 ·7H 2 O 1g / L, FeSO 4 ·7H 2 O 0.01g / L, pH 7.5.

[0091] (2) Primary screening medium: sodium alginate 10g / L, NaCl 15g / L, (NH4) 2 SO 4 5g / L, K 2 HPO 4 1g / L, MgSO 4 ·7H 2 O 1g / L, FeSO 4 ·7H 2 O 0.01g / L, pH 7.5. 1.8% (w / v) agar was added to the solid medium.

[0092] (3) The composition of the re-screening medium is the same as that of the primary screening medium, except that agar is not added.

[0093] 2. Screening of strains

[0094] (1) Enrichment: Weigh 5g of sandy soil collected near the seaweed breeding area in Fujian and mix with 100mL sterilized water evenly. Draw 1 mL of the above-mentioned sand and sterilized water and mix the supernatant to inoculate in 50 mL / 250 mL enrichment medium, and shake the fla...

Embodiment 2

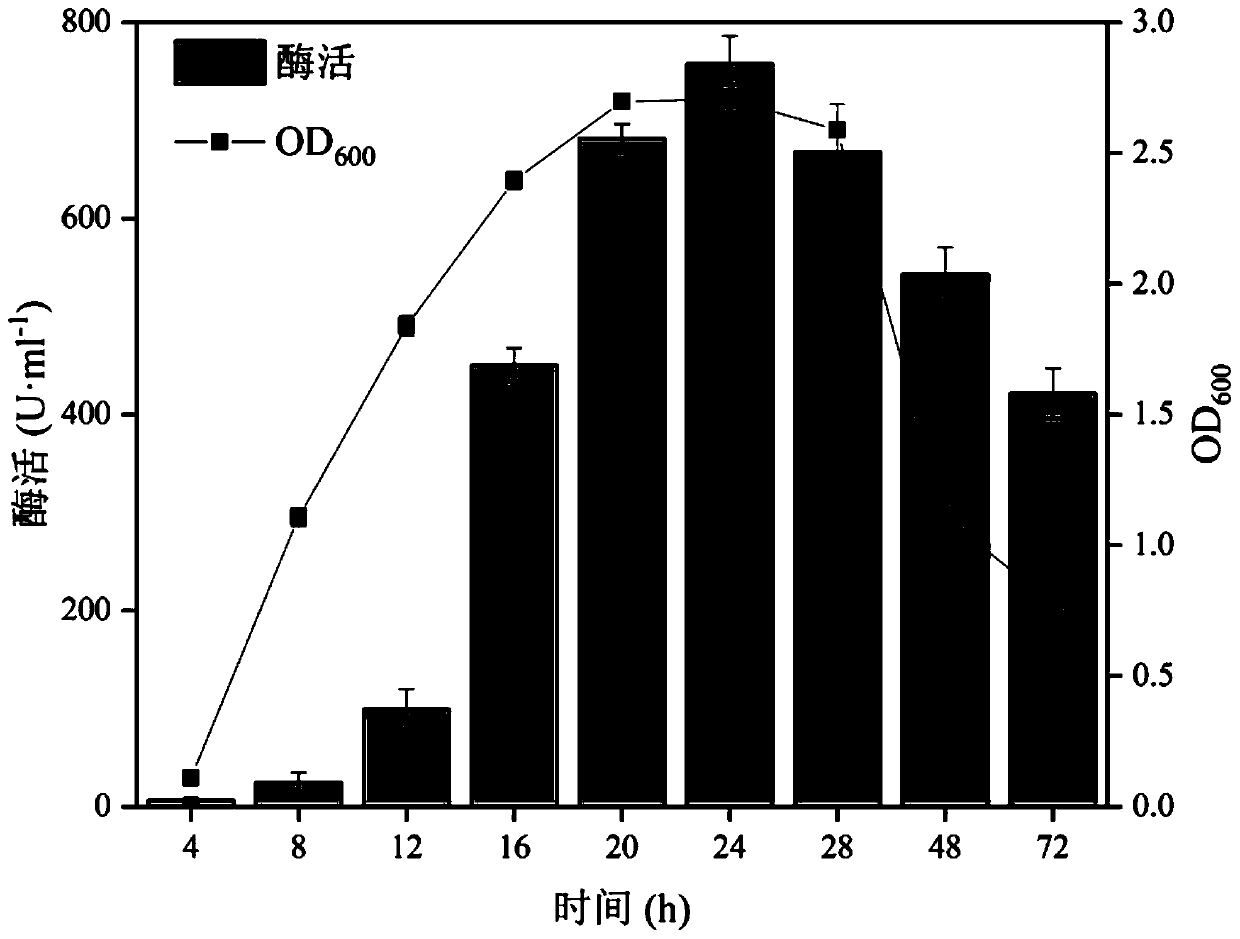

[0106] Example 2 Culture Condition Research of Microbulbifer sp.SH-1

[0107] (1) Inoculate the Microbulbifer sp.SH-1 preserved in glycerol on the seed medium (sodium alginate 10g / L, peptone 5g / L, yeast extract 5g / L, sodium chloride 10g / L, pH 7.0), in Shake culture at 28°C and 180rpm for 12h to obtain the logarithmic growth phase (OD 600 =0.6~0.8) seed solution.

[0108] (2) Inoculate the seed solution obtained in step (1) into a liquid fermentation medium (sodium alginate 10g / L, ammonium sulfate 5g / L, magnesium sulfate 0.2g / L, potassium dihydrogen phosphate 1g / L, sulfurous acid Iron 0.02g / L, sodium chloride 5g / L), respectively study the pH (4.5,5.5,6,6.5,7,7.5,8), culture temperature (25,28,32,35,40 ℃), liquid volume (15, 30, 50, 60, 75, 90mL, container volume is 250mL), inoculum volume (1, 2, 3, 4, 5% (v / v), shaker speed (120, 150, 180, 210, 240rpm) and other culture conditions on the enzyme production of strain SH-1.

[0109] The result is as Figures 12 to 16 It was s...

Embodiment 3

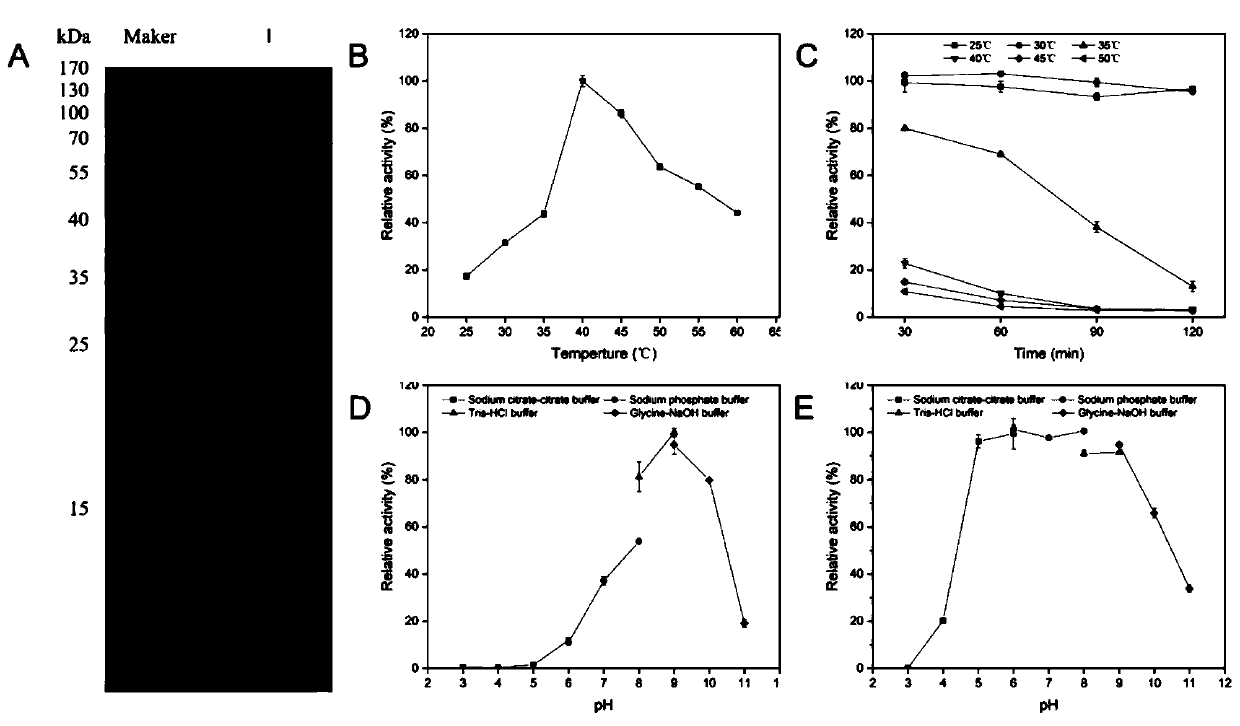

[0110] Example 3 Preparation of alginate lyase by Microbulbifer sp.SH-1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com