Dry powder bacterial agent for removing low-concentration copper ions in wastewater

A low-concentration, dry powder technology, applied in the field of environmental microorganisms, can solve problems such as difficulties in practical and industrial applications, inability to tolerate heavy metals, and few microbial resources, and achieve industrial applications, large bacterial loads, and high bacterial activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

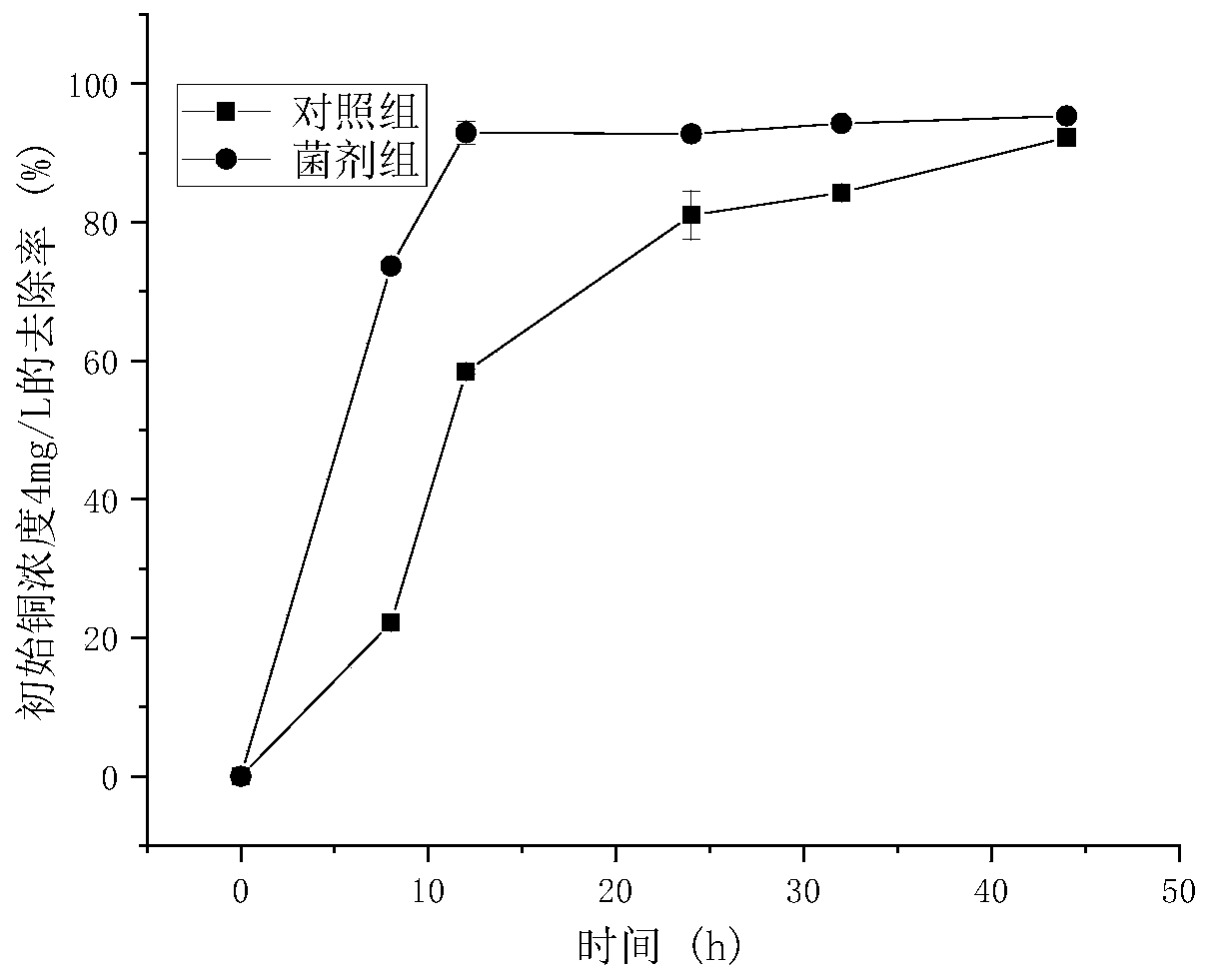

[0031] The dry powder bacterial agent for treating wastewater containing copper ions is prepared according to the following process:

[0032] After the self-isolated Bacillus cereus was isolated and purified by the plate streaking method, the strain was rejuvenated, and the Bacillus cereus was cultured in LB medium with a transfer ratio of 1% to the logarithmic growth phase OD 600 =1 to obtain a copper-tolerant bacterial fermentation broth.

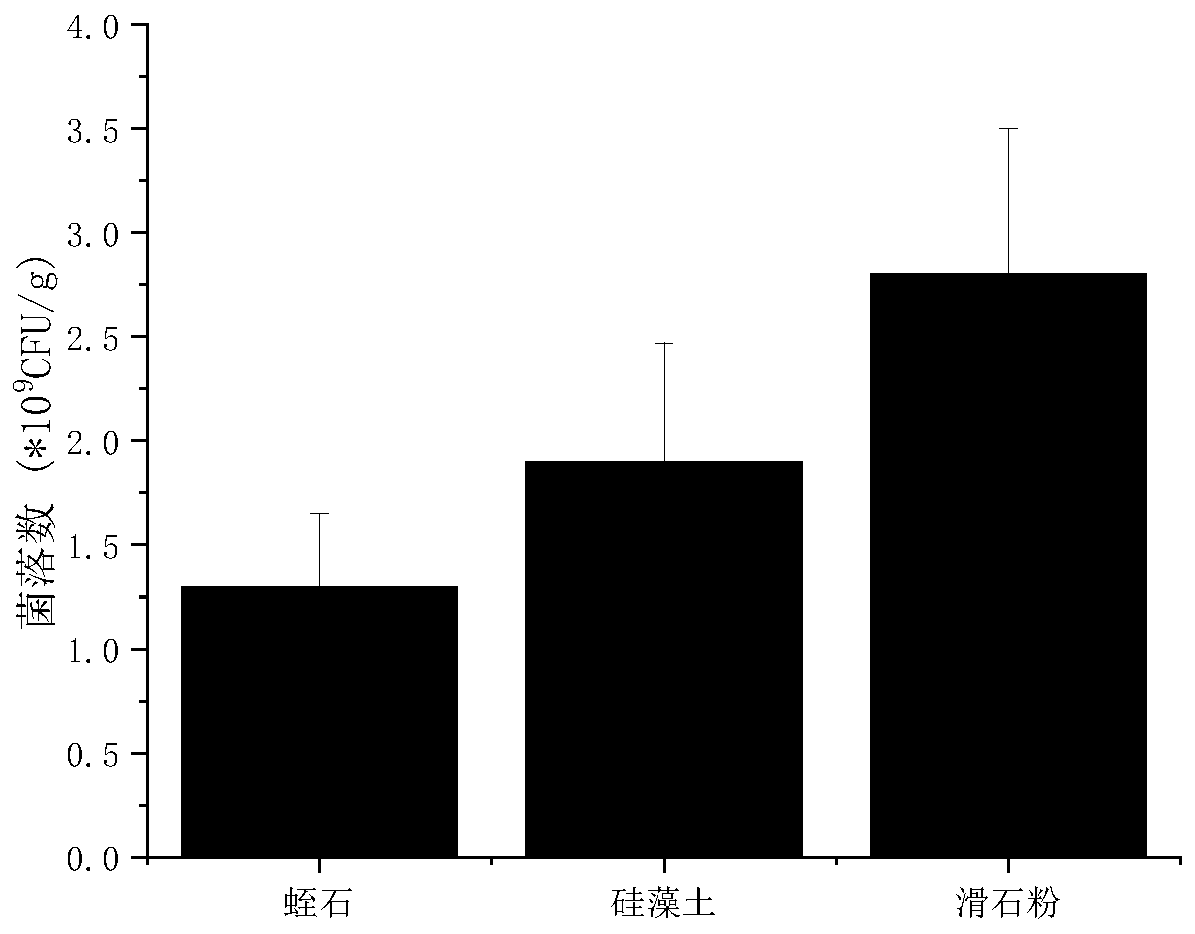

[0033] The immobilization carrier is selected as 150 mesh talcum powder.

[0034] The weight ratio of the copper-resistant bacterial fermentation broth to the immobilized carrier was 60:1. The copper-resistant bacterial fermentation broth was centrifuged at 8000rpm for 5min, and the supernatant was removed and washed repeatedly with phosphate buffered saline (PBS) and centrifuged 3 times. Wash and remove the bottom of the supernatant sludge and resuspend it into the LB medium after high temperature sterilization, and mix the resuspended ...

Embodiment 2

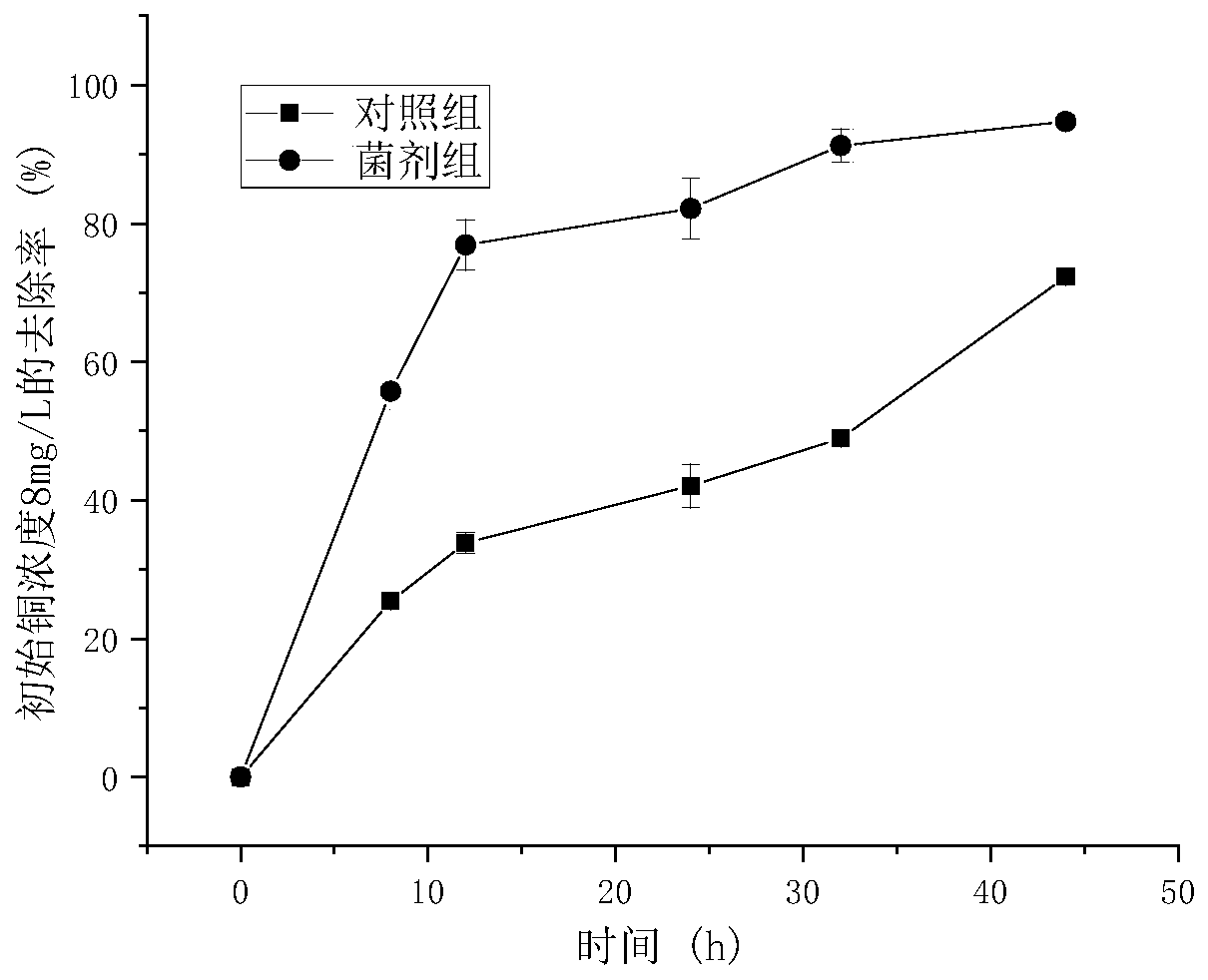

[0036] The dry powder bacterial agent for treating wastewater containing copper ions is prepared according to the following process:

[0037] After the self-isolated Bacillus cereus was isolated and purified by the streaking method on the plate, the strain was rejuvenated. The Bacillus cereus was transferred to LB medium at a transfer ratio of 5%, and cultured until the logarithmic growth phase OD600=1.1 to obtain copper-resistant bacteria fermentation broth.

[0038] The immobilized carrier is 90 mesh talcum powder.

[0039] The weight ratio of the copper-resistant bacterial fermentation broth to the immobilized carrier was 60:1. The copper-resistant bacterial fermentation broth was centrifuged at 8000rpm for 5min, and the supernatant was removed and washed repeatedly with phosphate buffered saline (PBS) and centrifuged 3 times. Wash and remove the supernatant from the bottom of the sludge and resuspend the LB medium after high temperature sterilization, and mix the resuspen...

Embodiment 3

[0041]The dry powder bacterial agent for treating wastewater containing copper ions is prepared according to the following process:

[0042] After the self-isolated Bacillus cereus was isolated and purified by the streaking method on the plate, the strain was rejuvenated. The Bacillus cereus was transferred to LB medium at a transfer ratio of 5%, and cultured until the logarithmic growth phase OD600=1.1 to obtain copper-resistant bacteria fermentation broth.

[0043] 80 mesh talcum powder was selected as the immobilization carrier.

[0044] The weight ratio of the copper-resistant bacterial fermentation broth to the immobilized carrier was 60:1. The copper-resistant bacterial fermentation broth was centrifuged at 8000rpm for 5min, and the supernatant was removed and washed repeatedly with phosphate buffered saline (PBS) and centrifuged 3 times. Wash and remove the supernatant from the bottom of the sludge and resuspend the LB medium after high temperature sterilization, and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viable count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com