Method for preparing high-efficiency long-life porous nickel-molybdenum alloy for hydrogen production by water electrolysis

A molybdenum alloy and porous nickel technology, applied in the field of high-efficiency and long-life porous nickel-molybdenum alloy preparation, can solve the problems of few active sites, small electrode specific surface area, poor stability, etc., and achieve a small Tafel slope value and a large hydrogen evolution current. The effect of excellent density and electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Nickel and molybdenum powders are prepared at an atomic ratio of 1:3, and then Mg powder is added as a pore-forming agent, and the mass percentage of Mg powder is 10%. Then use a tablet press to press into a billet, wherein the pressing pressure is 600 MPa, and the holding time is 30 seconds. Then place the obtained sample in an alumina crucible, and then put the crucible into a tube-type sintering furnace; then fill the tube with argon gas with a purity of 99.999%, and control the output power of the tube-type sintering furnace at a rate of 20°C / min. The heating rate was heated to 900°C, and the temperature was maintained for 30 minutes. Then the tubular sintering furnace was closed, and the sample was cooled with the furnace to obtain a porous nickel-molybdenum alloy that can be used as a cathode material for hydrogen production by electrolysis of water.

[0020] Microstructure and electrolytic performance analysis:

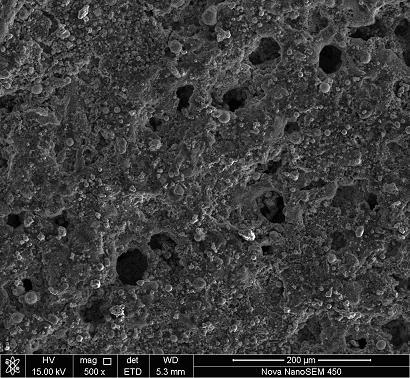

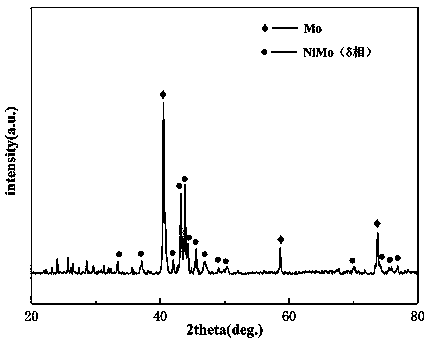

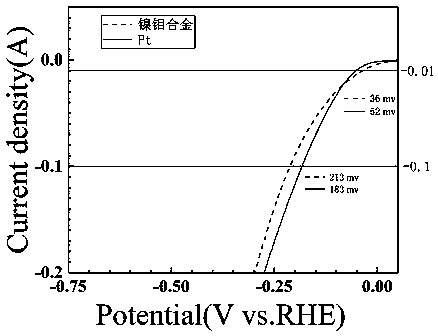

[0021] from figure 1 It can be seen that there a...

Embodiment 2

[0026] Nickel and molybdenum powders are prepared at an atomic ratio of 3:1, and then Mg powder is added as a pore-forming agent, and the mass percentage of Mg powder is 13%. Then use a tablet press to press into a billet, wherein the pressing pressure is 700 MPa, and the holding time is 30 seconds. Then place the obtained sample in an alumina crucible, and then put the crucible into a tubular sintering furnace; then fill the tube with argon gas with a purity of 99.999%, and control the output power of the tubular sintering furnace at a rate of 30°C / min. The heating rate was heated to 1000°C, and the temperature was maintained for 40 minutes. Then the tubular sintering furnace was closed, and the sample was cooled with the furnace to obtain a porous nickel-molybdenum alloy that can be used as a cathode material for hydrogen production by electrolysis of water.

Embodiment 3

[0028] Nickel and molybdenum powders are prepared at an atomic ratio of 5:1, and then Mg powder is added as a pore-forming agent, and the mass percentage of Mg powder is 15%. Then use a tablet press to press into a billet, wherein the pressing pressure is 800 MPa, and the holding time is 30 seconds. Then place the obtained sample in an alumina crucible, and then put the crucible into a tube-type sintering furnace; then fill the tube with argon gas with a purity of 99.999%, and control the output power of the tube-type sintering furnace at a rate of 40°C / min. The heating rate was heated to 1100°C, and the temperature was maintained for 50 minutes. Then the tubular sintering furnace was closed, and the sample was cooled with the furnace to obtain a porous nickel-molybdenum alloy that can be used as a cathode material for hydrogen production by electrolysis of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com