Preparation method of PCL (polycaprolactone)/CNTs (carbon nanotubes) compound electrospun film

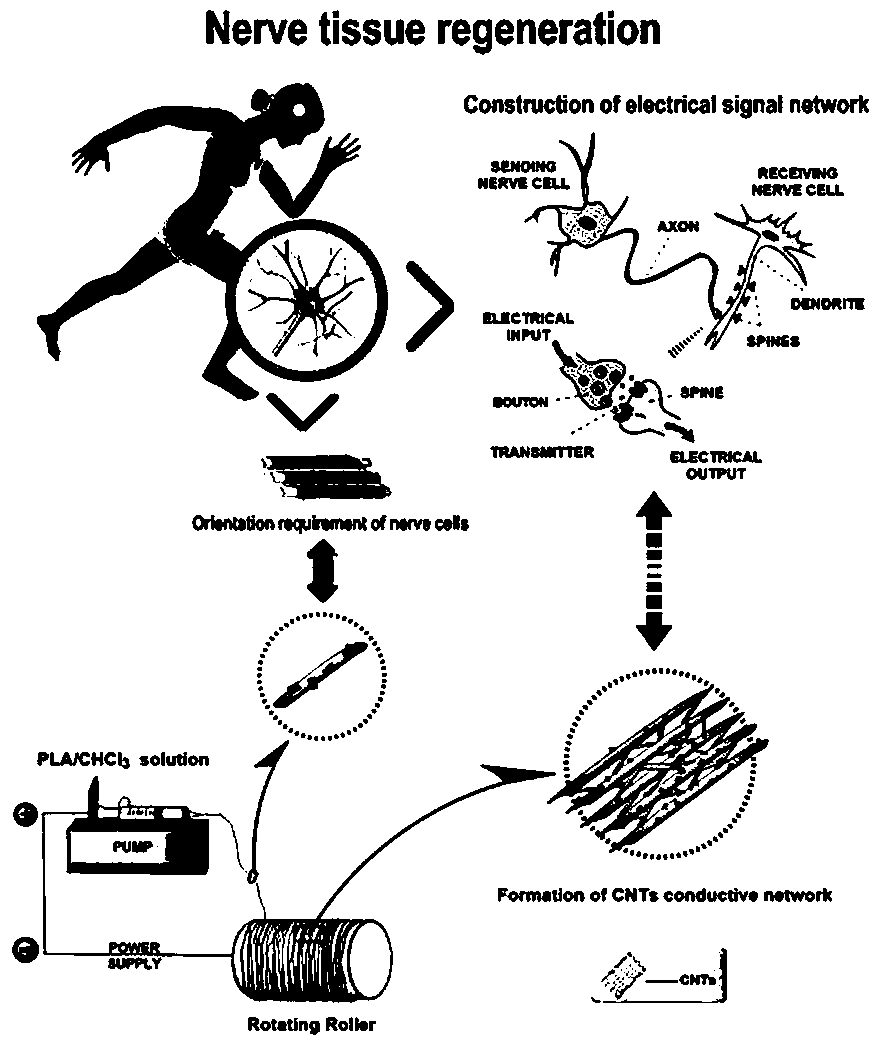

A technology of electrospinning and mixed solution, applied in the field of materials science, to improve repair efficiency, promote neuronal differentiation, and enhance electrical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

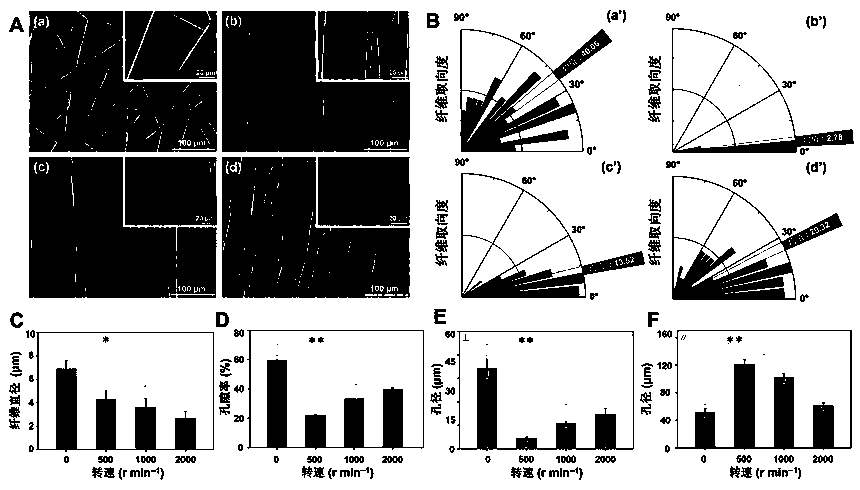

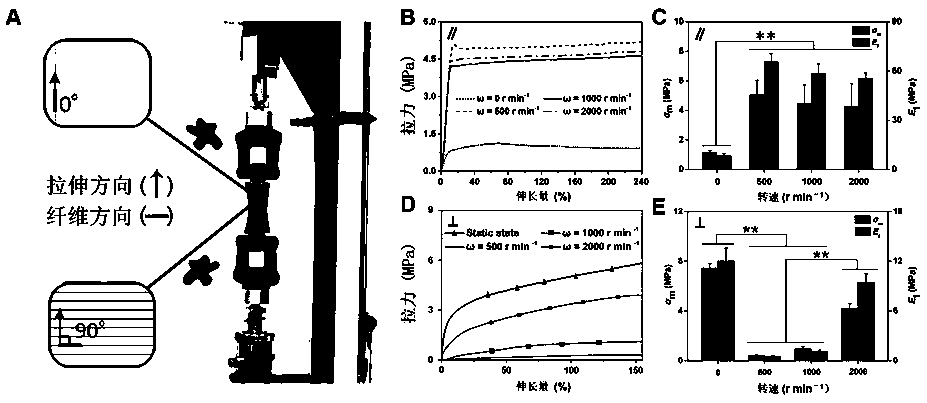

[0041] (1) Weigh a certain amount of polycaprolactone (PCL) and dissolve it in chloroform, stir for 24 h until the solution is uniform and transparent, and the concentration of PCL is 10 wt.%;

[0042] (2) In order to prepare PCL / CNTs composite electrospun fibers, a certain concentration of CNTs was added to the polymer solution (10wt.%), and the CNTs were kept in a good dispersion state by continuous ultrasonication for 30 minutes;

[0043] (3) Inhale PCL or PCL / CNTs solution into a 10 mL plastic syringe, press 0.10 mm·min –1 Launched, the high-voltage power supply applied an electric field of 15 kV during the spinning process;

[0044] (4) The obtained PCL or PCL / CNTs electrospun was collected on a metal cylindrical roller 14 cm away from the needle tip (D=16 cm, L=22 cm);

[0045] (5) In order to obtain oriented fibers, set the rotation speed of the drum collection device to 1000 rpm, and control the thickness of the final electrospun fiber membrane to 150 μm;

[0046] (6...

Embodiment 2

[0048] (1) Weigh a certain amount of polycaprolactone (PCL) and dissolve it in chloroform, stir for 24 h until the solution is uniform and transparent, and the concentration of PCL is 12 wt.%;

[0049] (2) In order to prepare PCL / CNTs composite electrospun fibers, a certain concentration of CNTs was added to the polymer solution (10wt.%), and the CNTs were kept in a good dispersion state by continuous ultrasonication for 30 minutes;

[0050] (3) Inhale PCL or PCL / CNTs solution into a 10 mL plastic syringe, press 0.10 mm·min –1 Launched, the high-voltage power supply applied an electric field of 15 kV during the spinning process;

[0051] (4) The obtained PCL or PCL / CNTs electrospun was collected on a metal cylindrical roller 14 cm away from the needle tip (D=16 cm, L=22 cm);

[0052] (5) In order to obtain oriented fibers, set the rotation speed of the drum collection device to 1000 rpm, and control the thickness of the final electrospun fiber membrane to 160 μm;

[0053] (6...

Embodiment 3

[0055] (1) Weigh a certain amount of polycaprolactone (PCL) and dissolve it in chloroform, stir for 24 h until the solution is uniform and transparent, and the concentration of PCL is 10 wt.%;

[0056] (2) In order to prepare PCL / CNTs composite electrospun fibers, a certain concentration of CNTs was added to the polymer solution (15wt.%), and the CNTs were kept in a good dispersion state by continuous ultrasonication for 30 minutes;

[0057] (3) Inhale PCL or PCL / CNTs solution into a 10 mL plastic syringe, press 0.10 mm·min –1 Launched, the high-voltage power supply applied an electric field of 15 kV during the spinning process;

[0058] (4) The obtained PCL or PCL / CNTs electrospun was collected on a metal cylindrical roller 14 cm away from the needle tip (D=16 cm, L=22 cm);

[0059] (5) In order to obtain oriented fibers, set the rotation speed of the drum collection device to 1000 rpm, and control the thickness of the final electrospun fiber membrane to 165 μm;

[0060] (6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com