Hole transport material of perovskite solar cell, and preparation method and application of hole transport material

A technology of hole transport materials and solar cells, which is applied in the field of solar cell materials, can solve problems such as insufficient matching of energy band structures, insufficient open circuit voltage and fill factor of perovskite cells, and low carrier transport efficiency, achieving photoelectric Improved conversion efficiency, good matching, and improved energy band structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

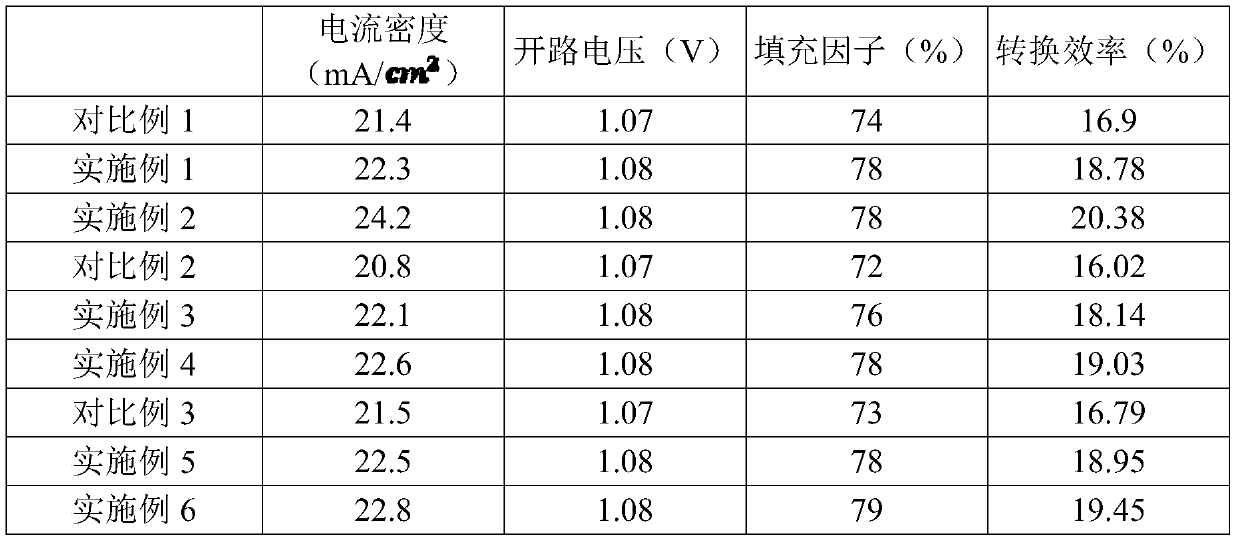

Embodiment 1

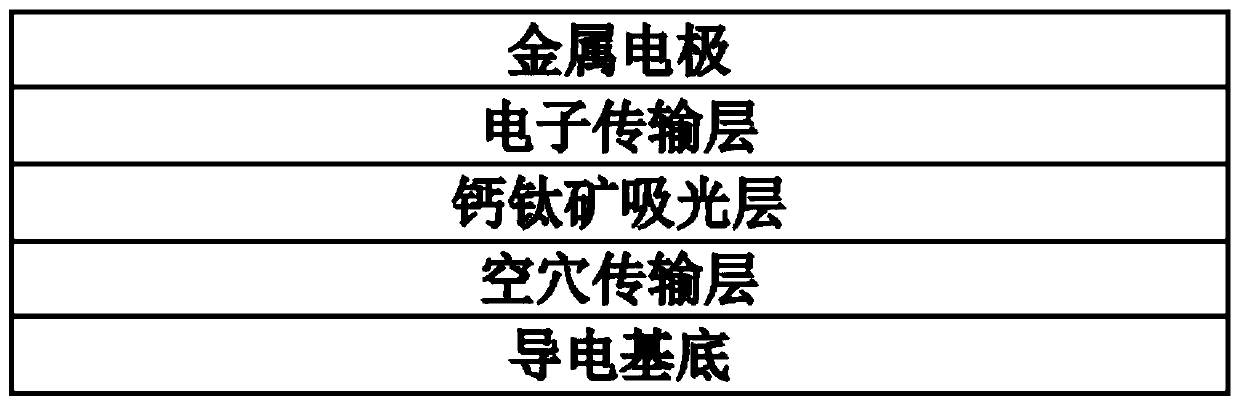

[0041] The present embodiment provides a kind of perovskite solar cell, it has such as figure 1 The structure shown was prepared by the following steps:

[0042] (1) Glass cleaning: Etch the FTO glass with zinc powder and dilute hydrochloric acid, and cut the etched glass into small glasses of 2.5×2.5 cm. Sonicate the small glass with detergent, deionized water, ethanol, and acetone for 20 minutes each. Blow dry with nitrogen and treat in UV ozone machine for 30 minutes.

[0043] (2) Preparation of hole transport layer Preparation of precursor solution: preparing an inorganic hole transport material solution containing rare metal element ions. Mix indium chloride with a molar ratio of 0.5% and nickel oxide as the solute, then add 35mL of acetonitrile and 5mL of ethanol to it, and rotate it on a rotating table at 65°C for 12h. If there is still a small amount of solute in the solution, add an appropriate amount of Add 1-2mL of DMSO to prepare a nickel oxide concentration of ...

Embodiment 2

[0049] This embodiment provides a perovskite solar cell, which is prepared through the following steps:

[0050] (1) Glass cleaning: Etch the FTO glass with zinc powder and dilute hydrochloric acid, and cut the etched glass into small glasses of 2.5×2.5 cm. Sonicate the small glass with detergent, deionized water, ethanol, and acetone for 20 minutes each. Blow dry with nitrogen and treat in UV ozone machine for 30 minutes.

[0051] (2) Preparation of hole transport layer Preparation of precursor solution: preparing an inorganic hole transport material solution containing rare metal element ions. Mix beryllium bromide and nickel oxide with a molar ratio of 0.5% as a solute, then add 35mL of acetonitrile and 5mL of ethanol to it, and rotate it on a rotating table at 65°C for 5 hours. If there is still a small amount of solute in the solution, add it in an appropriate amount 1-2mL of DMSO, the prepared nickel oxide concentration is 10mg / mL.

[0052] (3) Preparation of the hole...

Embodiment 3

[0064] This embodiment provides a perovskite solar cell, which is prepared through the following steps:

[0065] (1) Glass cleaning: Etch the FTO glass with zinc powder and dilute hydrochloric acid, and cut the etched glass into small glasses of 2.5×2.5 cm. Sonicate the small glass with detergent, deionized water, ethanol, and acetone for 20 minutes each. Blow dry with nitrogen and treat in UV ozone machine for 30 minutes.

[0066] (2) Preparation of hole transport layer Preparation of precursor solution: preparing an inorganic hole transport material solution containing rare metal element ions. Mix indium chloride and CuI with a molar ratio of 0.3% as a solute, then add 35mL of acetonitrile and 5mL of ethanol, and then rotate on a rotary table for 5h. If there is still a small amount of solute in the solution, add 1- 2 mL of DMSO.

[0067] (3) Preparation of the hole transport layer: heating the glass in step (1), filtering the prepared precursor solution of the hole trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com