Application method of phase inversion emulsification technology in cosmetics

A technology of phase-inversion emulsification and application method, which is applied in the field of application method of phase-inversion emulsification technology in cosmetics and its products, which can solve the problems of increasing the complexity of cosmetic preparation and achieve stable product system, simple process and small particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

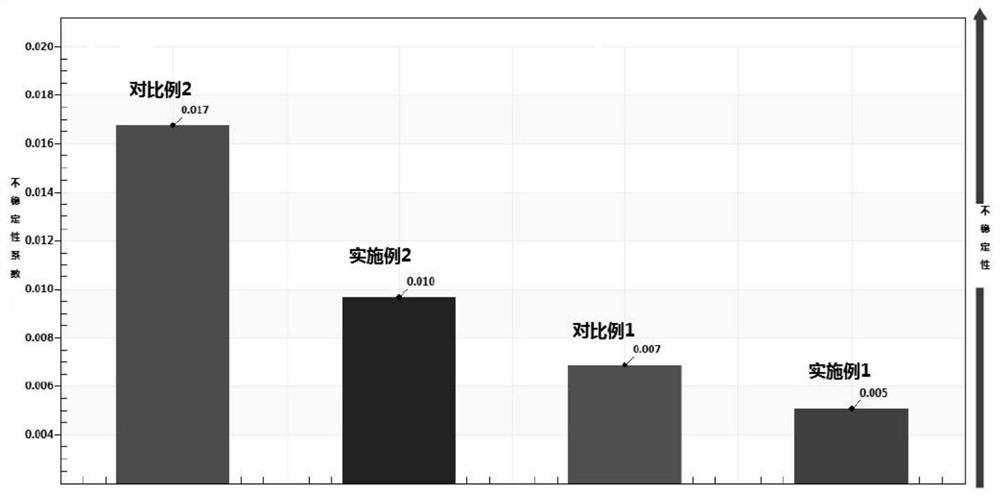

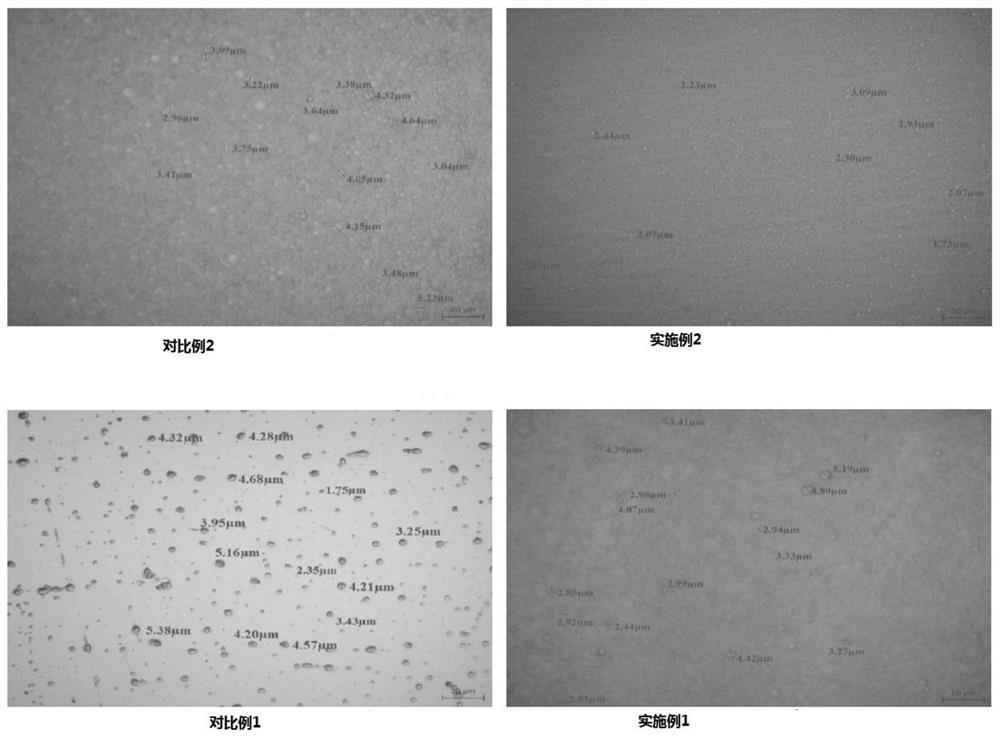

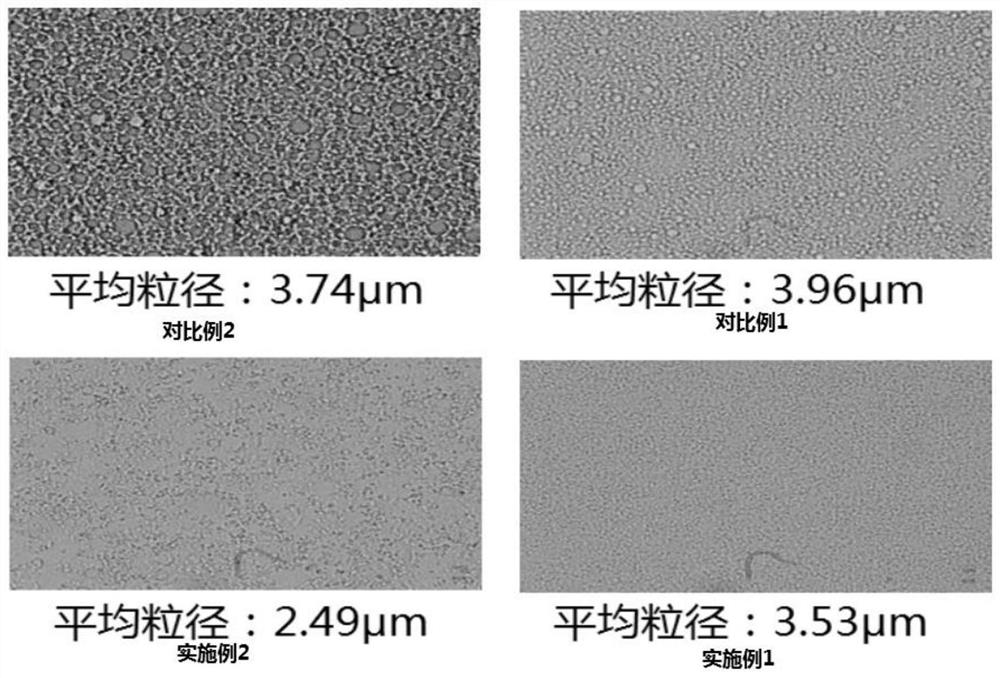

Embodiment 1

[0121] Embodiment 1 of the present invention provides a day cream obtained by applying the phase inversion emulsification technology to cosmetics. In parts by weight, the raw materials used include 65 parts of water phase raw materials, 30 parts of oil phase raw materials, and 1.5 parts of group A points and 0.3 parts of B component;

[0122] The A component includes xanthan gum and 1.3-butanediol, and the weight ratio of the xanthan gum to 1.3-butanediol is 1:4;

[0123] Component B includes deionized water and aminomethyl propanol, the weight ratio of deionized water to aminomethyl propanol is 1:0.35;

[0124] The water phase raw material comprises allantoin, thickener, alcohol, hydrogenated lecithin, disodium edetate, and deionized water; the allantoin, thickener, alcohol, hydrogenated lecithin, ethyl The weight ratio of disodium diamine tetraacetate and deionized water is 1:20:1.25:125:0.65:500; the thickener is Aculyn33; the alcohol is glycerin and 1,3-butanediol, so Th...

Embodiment 2

[0139] Embodiment 2 of the present invention provides the emulsion obtained by using the phase inversion emulsification technology in the application method of cosmetics. In parts by weight, the raw materials used include 67 parts of water phase raw materials, 25 parts of oil phase raw materials, 2.5 parts of C component, 3.5 parts D component, 0.4 parts E component and 1.6 parts F component;

[0140] The water phase raw materials include emulsifier, alcohols, allantoin, Austenitic seaweed extract, disodium edetate and deionized water, the emulsifier, alcohols, allantoin, Austenitic The weight ratio of seaweed extract, disodium edetate and deionized water is 1:3.5:0.1:0.005:0.025:30; the emulsifier is potassium cetyl phosphate; the alcohols include 1 , 3-butanediol and D-panthenol, the weight ratio of the 1,3-butanediol to D-panthenol is 1:0.16;

[0141] The oil phase raw materials include titanium dioxide, emulsifier, vitamin E, dioctyl carbonate, sunscreen and cetearyl alco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com