High-energy cleaning and repairing integrated equipment

A cleaning equipment and high-energy technology, which is applied in chemical instruments and methods, cleaning methods and utensils, metal material coating processes, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

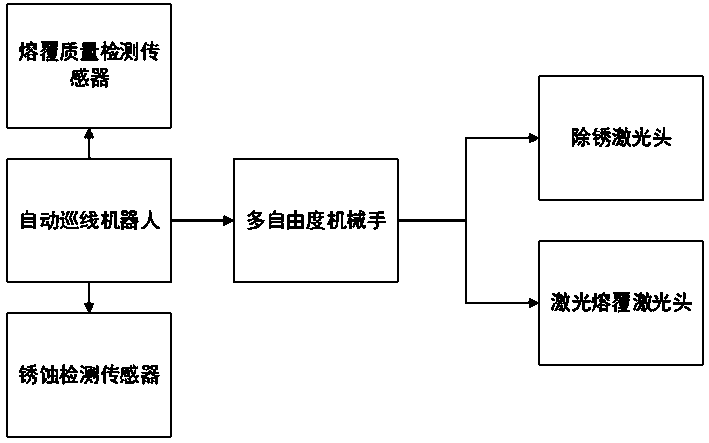

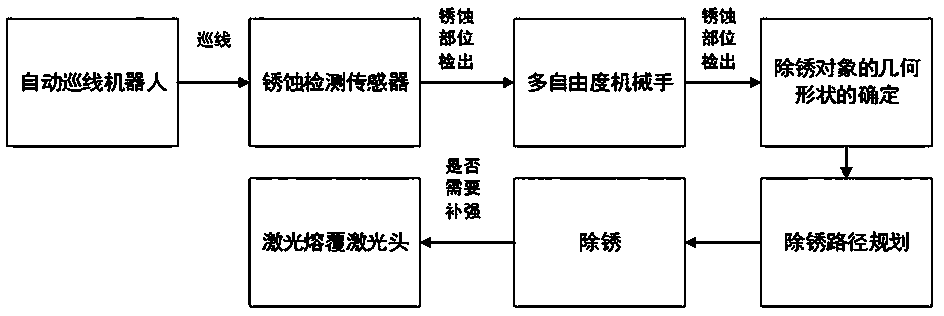

[0037] Embodiment one: see figure 1 As shown, a high-energy beam cleaning and repairing integrated equipment includes a line inspection robot, a cleaning system and a cladding system, and the control system of the line inspection robot serves as the control system of the entire equipment. The line inspection robot is respectively connected with a rust detection sensor and a cladding quality detection sensor; the line inspection robot has a multi-degree-of-freedom manipulator, and the derusting processing head in the cleaning system and the cladding processing head in the cladding system are respectively controlled by the multi-degree-of-freedom manipulator. Orientation and positioning of manipulator.

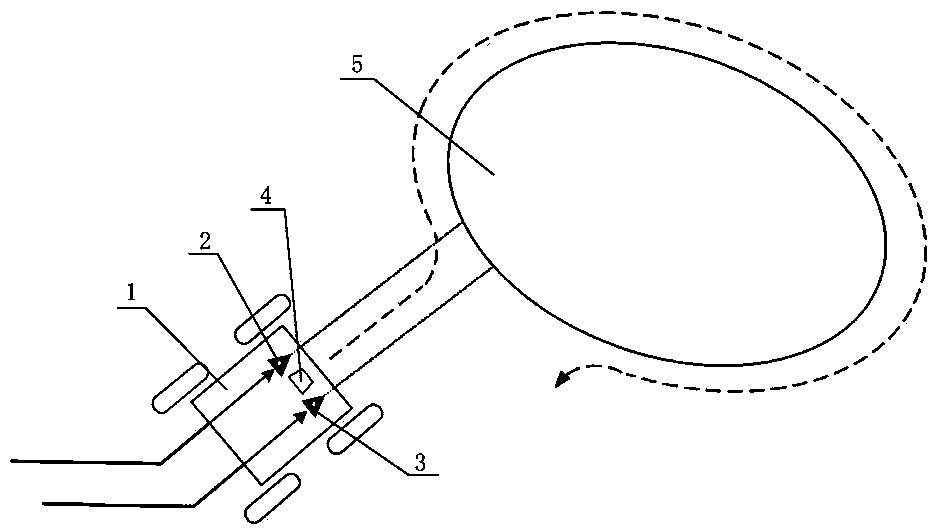

[0038] In this embodiment, the line inspection robot is based on a mobile robot, loaded with a machine vision detection instrument and an automatic navigation system, thereby realizing automatic inspection of the cleaned equipment. as attached image 3 As shown, the line inspe...

Embodiment 2

[0040] Embodiment 2: An integrated laser cleaning and repairing device, including a line inspection robot, a laser cleaning system and a laser cladding system, and the control system of the line inspection robot serves as the control system of the entire device. The line inspection robot is respectively connected with a corrosion detection sensor and a cladding quality detection sensor; the line inspection robot has a multi-degree-of-freedom manipulator, and the derusting laser head in the laser cleaning system and the cladding laser head in the laser cladding system are respectively controlled by the Multi-degree-of-freedom manipulator guide positioning.

[0041] In this embodiment, the line inspection robot is composed of a mobile robot and a submarine. The mobile robot and the submarine are respectively equipped with machine vision detection instruments, and the submarine is controlled by the mobile robot through wireless communication equipment.

[0042] Taking the hull of a...

Embodiment 3

[0043] Embodiment 3: An integrated high-energy cleaning and repairing device, including a high-energy beam generating device, a cladding system and a control system, wherein the high-energy beam generating device adopts a high-energy plasma beam generating device. A line inspection robot and a corrosion detection sensor are provided, and the corrosion detection sensor, the high-energy beam generating device and the cladding system are all arranged on the line inspection robot, and the control system controls the high-energy beam generating device to The rail surface of the high-speed rail is cleaned. When the corrosion degree of the surface of the cleaned equipment exceeds the set threshold, after the cleaning is completed, the control system controls the plasma cladding system to perform surface protection and repair work on the corroded position of the equipment surface. The high energy The emission power density of the plasma beam generator is >10 4 W / cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com