Oil-containing wastewater treatment process combining ultrafiltration membrane and electro-catalysis method

A wastewater treatment and ultrafiltration membrane technology, which is applied in the direction of neutralization water/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of emulsified oil and cutting oil wastewater, and the removal effect is not ideal , Poor biodegradability and other problems, to achieve the effect of improved treatment effect, easy automation, and low filtration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

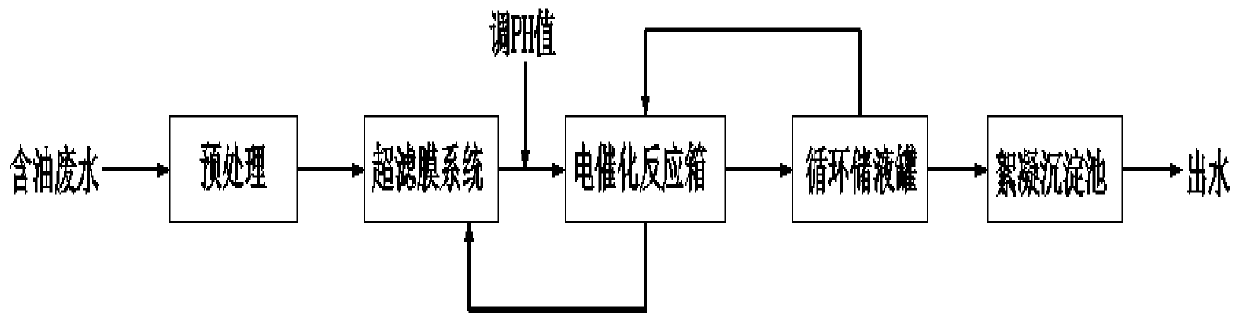

[0021] The oily wastewater treatment process combining ultrafiltration membrane and electrocatalysis includes the following steps:

[0022] Step 1. Pre-treat the wastewater containing emulsion;

[0023] Step 2. Input the wastewater into the ultrafiltration membrane system for cross-flow filtration to concentrate the grease components, suspended solids and other macromolecular substances in it, so that the volume of the waste liquid is greatly reduced; the residence time of the wastewater in the ultrafiltration membrane system is 3~5min.

[0024] Step 3. Input the effluent of the ultrafiltration membrane system into the electrocatalytic reaction box, adjust the Ph value, add activated carbon, and perform the electrocatalytic oxidation reaction; the residence time of the wastewater in the electrocatalytic reaction box is 10 minutes.

[0025] Step 4. The effluent of the electrocatalytic reaction box is divided into two parts, the upper clear liquid is returned to the circulating liquid s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com