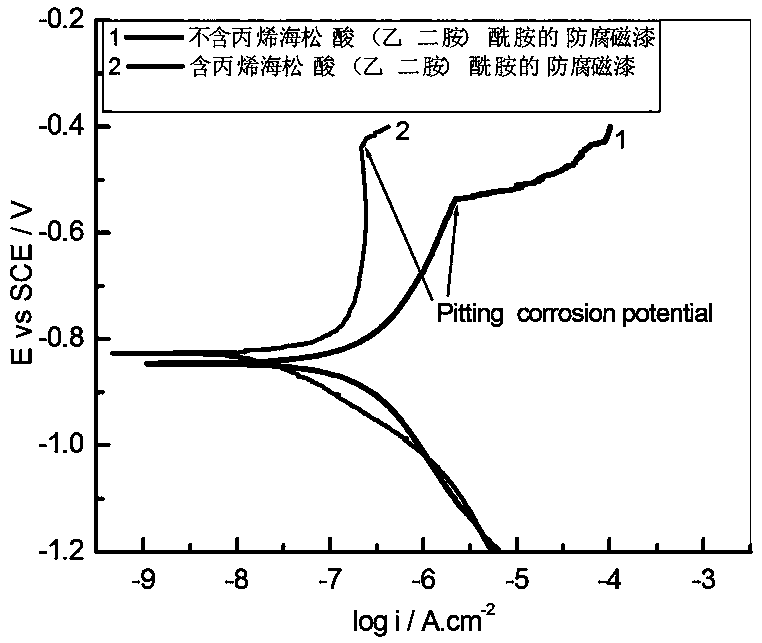

Preparation method of rosin-based short-oil alkyd resin anti-corrosive enamel paint with high pitting potential

A technology of alkyd resin and anti-corrosion enamel, applied in the field of enamel, can solve the problems of low pitting potential, low pitting resistance, improper matching, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] 1. Treatment of 6063 aluminum alloy sheet

[0013] The 6063 aluminum alloy sheet was polished with 1.0 μm and 0.3 μm alumina powder on a polishing cloth in turn, then placed in 5% hydrochloric acid for 5 minutes, then placed in deionized water for 5 minutes, and finally placed in anhydrous Sonicated in ethanol for 6 min and dried for later use.

[0014] 2. Preparation of anti-corrosion enamel with and without acrylpimaric acid (ethylenediamine) amide

[0015] Add 25 parts by weight of dry short oil alkyd resin, 2 parts by weight of acrylpimaric acid (ethylenediamine) amide and 50 parts by weight of o-xylene solvent into the reaction tank and stir evenly, then continue to add 15 parts by weight Talc powder, 15 parts by weight of bentonite, 2 parts by weight of dispersant polyethylene glycol 200, 2 parts by weight of leveling agent polyether modified polydimethylsiloxane interpolymer, 1 part by weight of drier Naphthenic acid iron salt is added together in the reaction ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap