Luzhou-flavor type six-grain liquor and production process thereof

A production process and Luzhou-flavored technology, which is applied in the field of wine making, can solve the problems of incomplete fermentation of raw materials, insufficient nutritional structure, high raw material prices, etc., and achieve the effects of thorough fermentation, improved wine yield, and high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

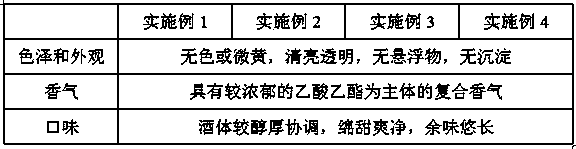

Examples

Embodiment 1

[0028] A preparation process of Luzhou-flavor Liuliangye, comprising the following steps:

[0029] Step 1. Prepare wine-making raw materials: Prepare the following raw materials in the proportion of parts by mass: 20 parts of rice, 25 parts of glutinous rice, 20 parts of wheat, 15 parts of sorghum, and 15 parts of buckwheat;

[0030] Step 2. Soaking: Pour all the brewing ingredients into a stainless steel rice steamer and soak in cold water. The soaking time is 20 minutes in summer;

[0031] Step 3. Cooking treatment: discharge the raw material liquid obtained after soaking and put it into a glass bottle, then scrape the surface of the raw material and turn on the boiler for cooking. The cooking time is: 20 minutes in summer, and then spray cold water for the first time, evenly Break up the raw materials, cover and steam for 30 minutes, then spray cold water for the second time, evenly disperse the raw materials, cover and steam for 30 minutes, the obtained raw materials are c...

Embodiment 2

[0038] A production process of strong-flavor Liuliangye, comprising the following steps:

[0039] Step 1, prepare brewing raw materials: prepare the following raw materials in proportion by mass and number: 28 parts of glutinous rice, 10 parts of rice, 15 parts of glutinous rice, 25 parts of wheat, 13 parts of sorghum, and 20 parts of buckwheat;

[0040] Step 2. Soaking: Pour all the brewing raw materials into the stainless steel rice cooker and soak in cold water. The soaking time is: 30min in autumn;

[0041] Step 3. Cooking treatment: discharge the raw material liquid obtained after soaking and put it into a glass bottle, then scrape the surface of the raw material and turn on the boiler for cooking. Disperse the raw materials, cover and steam for 20 minutes, and then spray cold water for the second time to evenly disperse the raw materials, cover and steam for 20 minutes, and the obtained raw materials are cooked but not rotten, and have no heart;

[0042] Step 4. Cool do...

Embodiment 3

[0048] A production process of strong-flavor Liuliangye, comprising the following steps:

[0049] Step 1, prepare brewing raw materials: prepare the following raw materials in proportion by mass and number: 35 parts of rice, 16 parts of rice, 30 parts of glutinous rice, 22 parts of wheat, 10 parts of sorghum, and 17 parts of buckwheat;

[0050] Step 2. Soaking: Pour all the brewing ingredients into a stainless steel rice cooker and soak in cold water. The soaking time is: 30min in spring;

[0051] Step 3. Cooking treatment: discharge the raw material liquid obtained after soaking and put it into a glass bottle, then scrape the surface of the raw material and turn on the boiler for cooking. The cooking time is: 20 minutes in spring, and then spray cold water for the first time, evenly Disperse the raw materials, cover and steam for 25 minutes, then spray cold water for the second time, evenly disperse the raw materials, cover and steam for 25 minutes, the obtained raw materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com