A kind of preparation method of novel cu-nanometer wc composite material

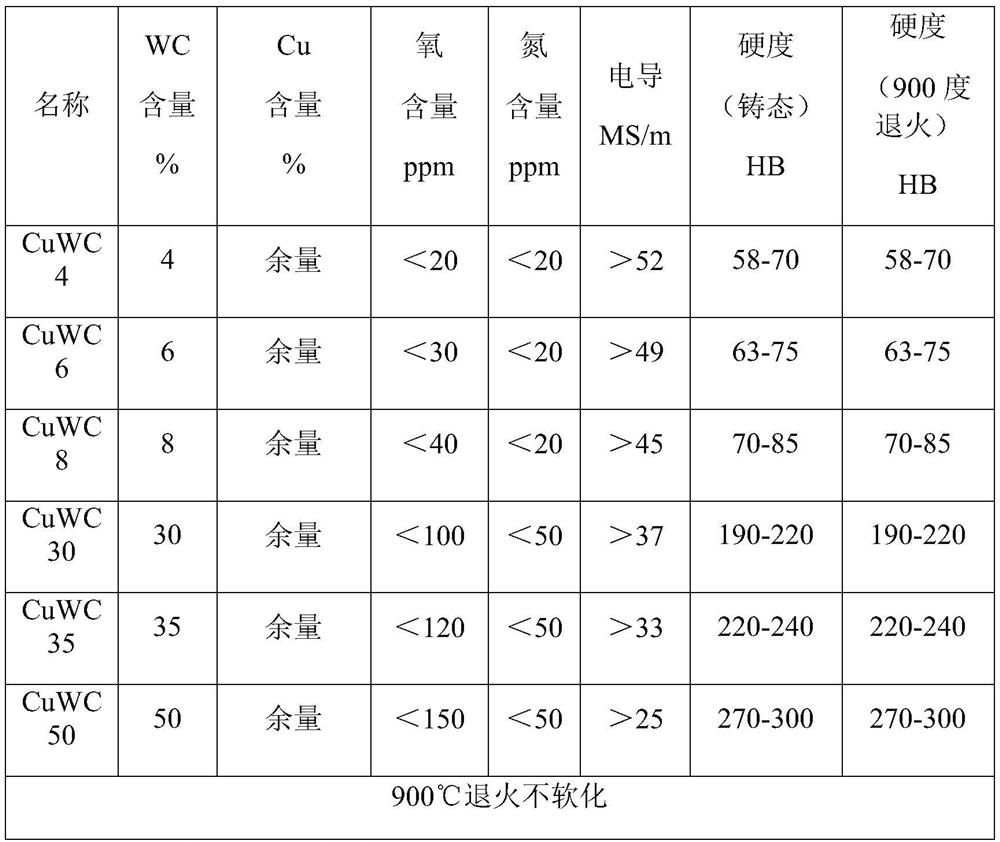

A kind of composite material and nanotechnology, which is applied in the field of preparation of new Cu-nano WC composite materials, can solve the problems of high gas content, low density, low electrical conductivity, etc., and achieve the effects of low gas content, increased strength and high electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: prepare CuWC4

[0028] Raw material selection copper powder (-200 mesh) purity ≥ 99.7%, WC (<500 nanometers) purity ≥ 99.0%, first mix copper powder and WC by weight Cu powder: WC powder = 75:25, and then use the weight ratio Mixing powder: steel ball = 100:100 for 3 hours; steel ball particle size 5mm, mixing machine speed 10 rpm;

[0029] The uniformly mixed mixed powder is loosely loaded into a graphite crucible, followed by vacuum sintering, when the vacuum degree reaches 5×10 -2 When it is below the pa level, heat it at 950°C for 2 hours to complete the sintering, and obtain a Cu-nano WC blank;

[0030] Proportion the Cu-nanometer WC billet and the oxygen-free copper block according to the weight ratio Cu:WC=96:4;

[0031] Put the prepared Cu-nanometer WC billet and oxygen-free copper block into the ceramic crucible, turn on the vacuum system of the vacuum induction melting equipment, when the vacuum degree reaches 3×10 -1 Gradient heating when pa ...

Embodiment 2

[0033] Embodiment 2: prepare CuWC6

[0034] Raw material selection copper powder (-200 mesh) purity ≥ 99.7%, WC (<500 nanometers) purity ≥ 99.0%, first mix copper powder and WC by weight Cu powder: WC powder = 90: 10, and then use the weight ratio Mixing powder: steel ball = 100:100 for 5 hours of powder mixing; the steel ball particle size is 12mm, and the speed of the powder mixing machine is 13 rpm;

[0035] The uniformly mixed mixed powder is loosely loaded into a graphite crucible, followed by vacuum sintering, when the vacuum degree reaches 5×10 -2 When it is below the pa level, heat it at 980°C for 2 hours to complete the sintering, and obtain a Cu-nanometer WC blank;

[0036] Proportion the Cu-nanometer WC billet and the oxygen-free copper block according to the weight ratio Cu:WC=94:6;

[0037] Put the prepared Cu-nanometer WC billet and oxygen-free copper block into the ceramic crucible, turn on the vacuum system of the vacuum induction melting equipment, when the ...

Embodiment 3

[0039] Embodiment 3: preparation CuWC8

[0040] Raw material selection copper powder (-200 mesh) purity ≥ 99.7%, WC (<500 nanometers) purity ≥ 99.0%, first mix copper powder and WC by weight Cu powder: WC powder = 80: 20, and then use the weight ratio Mixing powder: steel ball = 100:100 for 5 hours of powder mixing; the particle size of the steel ball is 16mm, and the speed of the powder mixing machine is 22 rpm;

[0041] The uniformly mixed mixed powder is loosely loaded into a graphite crucible, followed by vacuum sintering, when the vacuum degree reaches 5×10 -2 When it is below the pa level, heat it at 1000°C for 2 hours to complete the sintering, and obtain a Cu-nanometer WC blank;

[0042] Proportioning the Cu-nanometer WC billet and the oxygen-free copper block according to the weight ratio Cu:WC=92:8;

[0043] Put the prepared Cu-nanometer WC billet and oxygen-free copper block into the ceramic crucible, turn on the vacuum system of the vacuum induction melting equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com