Preparation method of polyester fabric

A fabric and polyester technology, applied in the field of polyester fabrics, can solve the problems of the mosquito repelling time of polyester fabrics and the types of mosquitoes, and achieve the effect of slowing down the volatilization time, increasing the use time, and preventing mildew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Such as Figure 1 to Figure 6 Shown, a kind of polyester fabric preparation method of the present invention comprises the following steps:

[0039] S1: Select and check raw materials: use 30D / 12F semi-gloss polyester filament as the warp yarn, 40D / 36F polyester filament as the weft yarn, and 50D / 72F polyester filament as the winding yarn, and check whether the raw material is dry or not Uniformity, whether the color fastness meets the quality index of the national textile industry; if it meets, continue the following operation; if not, continue to select raw materials until it meets the requirements; the correct selection and inspection of raw materials will help improve the production and production of polyester polyester fabrics Yield rate, the reason that the present invention selects the polyester yarn of 30D / 12F, 40D / 36F and 50D / 72F is that it is convenient to bleach it with bleaching liquid, and its bulkiness is high after bleaching, and it is easy to combine mosq...

Embodiment approach

[0054] As a specific embodiment of the present invention, the preparation method of the mosquito repellent liquid is to take 10% to 12% chrysanthemum, 15% to 17% mint leaves and 35% to 37% cocklebur into a centrifuge, and the centrifuge works 15-20min, and the power of the centrifuge is preferably 300-500W. After the centrifuge is finished, let it stand for 10 minutes, take out the mixture of chrysanthemum, mint leaves and cocklebur and put it in the high-speed disperser, and put 40 in the high-speed disperser. % ~ 42% citronella oil, continuously emulsified for 10-15min under the condition of high-speed disperser 8000-10000rpm, to form a uniform emulsion liquid, that is, get mosquito repellent; through the mutual cooperation of centrifuge and high-speed disperser, you can quickly get Repellent liquid;

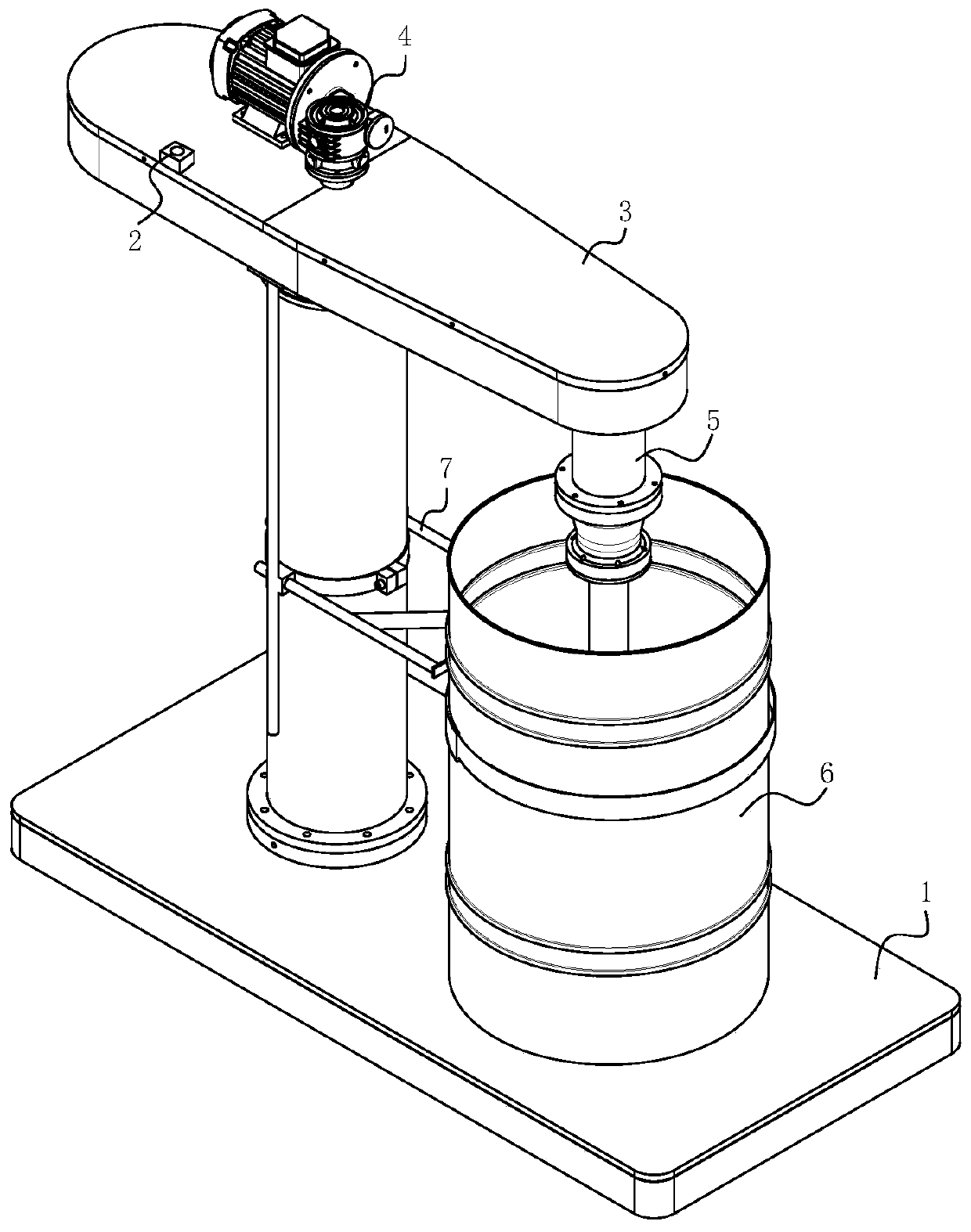

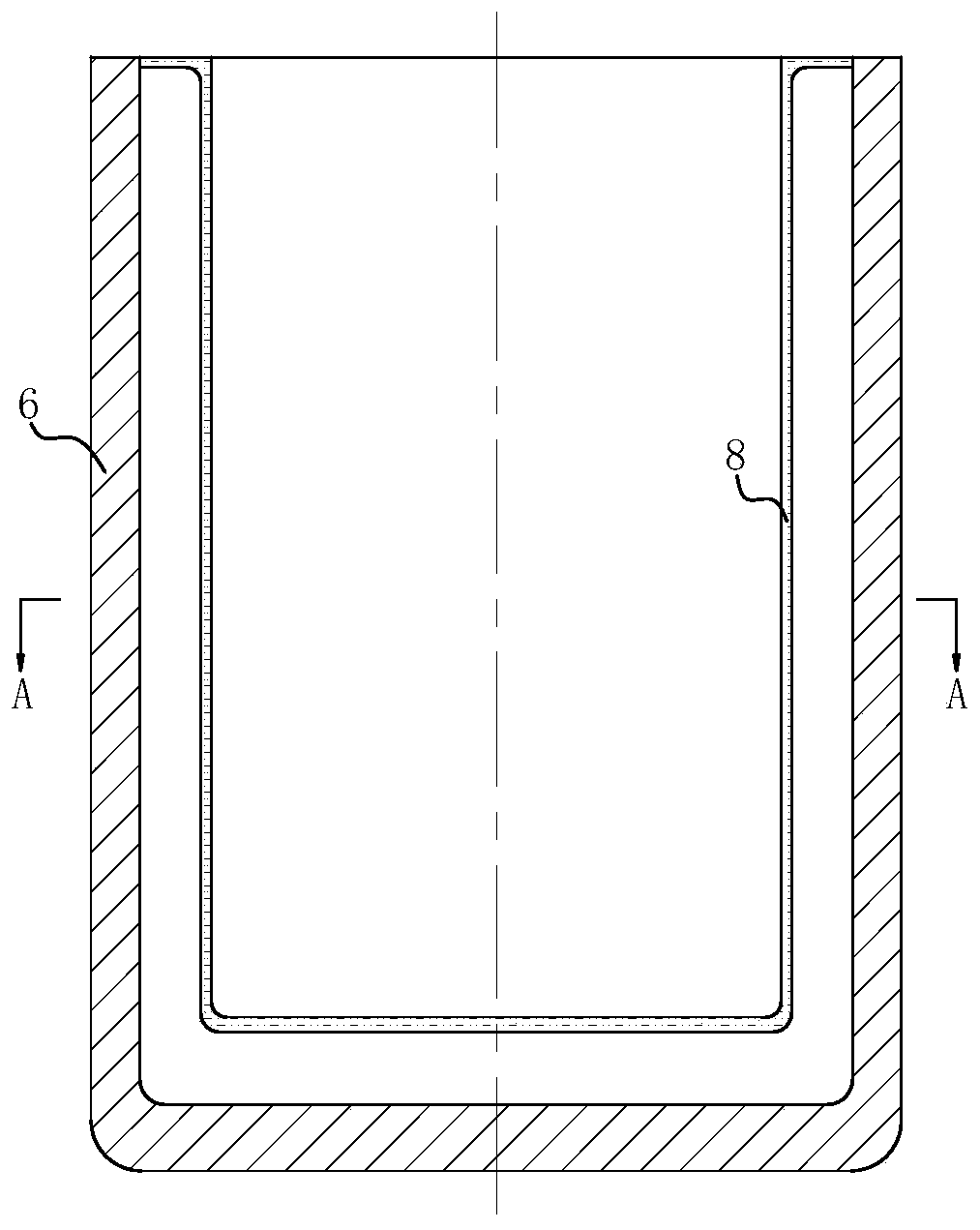

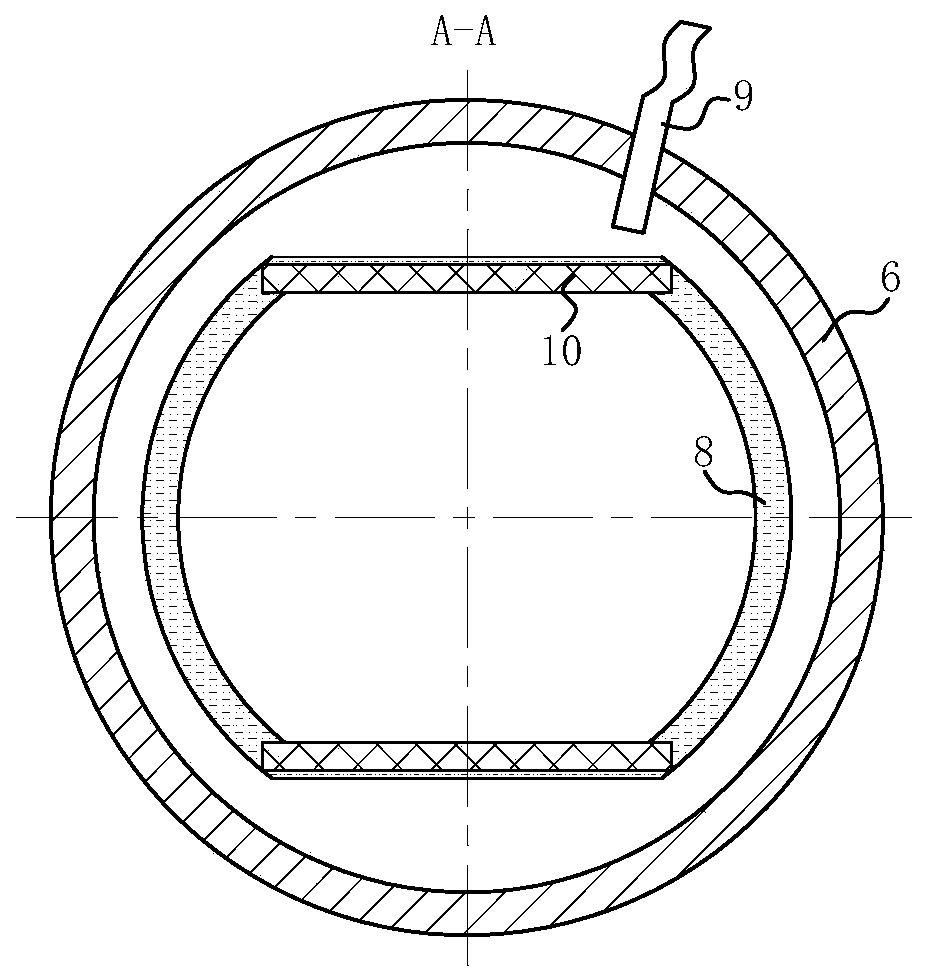

[0055]Wherein, the high-speed dispersing machine includes a support base 1 and an electric switch 2; one side of the support base 1 is fixedly connected with a support column ...

specific Embodiment approach

[0057] As a specific embodiment of the present invention, the vacuum magnetron sputtering coating needs to use: 1 to 12 vacuum chambers, 1 to 3 magnetron sputtering targets in each vacuum chamber, and 1 auxiliary enhanced ion source ~2; the auxiliary enhanced ion source is pure N2 or O2, with Ar as the sputtering gas, the flow ratio of the sputtering gas and the auxiliary enhanced ion gas is 1:3; the vacuum degree in the reaction chamber is 210-300Pa, The sputtering power is 1800-2600W, and the gas pressure is 1.0-2.0Pa; through this coating method, a layer of ionic film can be attached to the surface of polyester fabric, which helps to slow down the loss of mosquito repellent liquid components on polyester fabric and improve the quality of polyester fabric. The use time of fabric repellent.

[0058] As a specific embodiment of the present invention, the polyester fabric is suitable for making tents, curtains, field work clothes, etc.; the polyester fabric made by the above me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com