RG-6 copper-coated steel coaxial cable and fabrication method thereof

A coaxial cable, RG-6 technology, applied in the field of RG-6 copper-clad steel coaxial cable and its preparation, can solve problems such as difficulty in improving the quality of coaxial cable signal transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

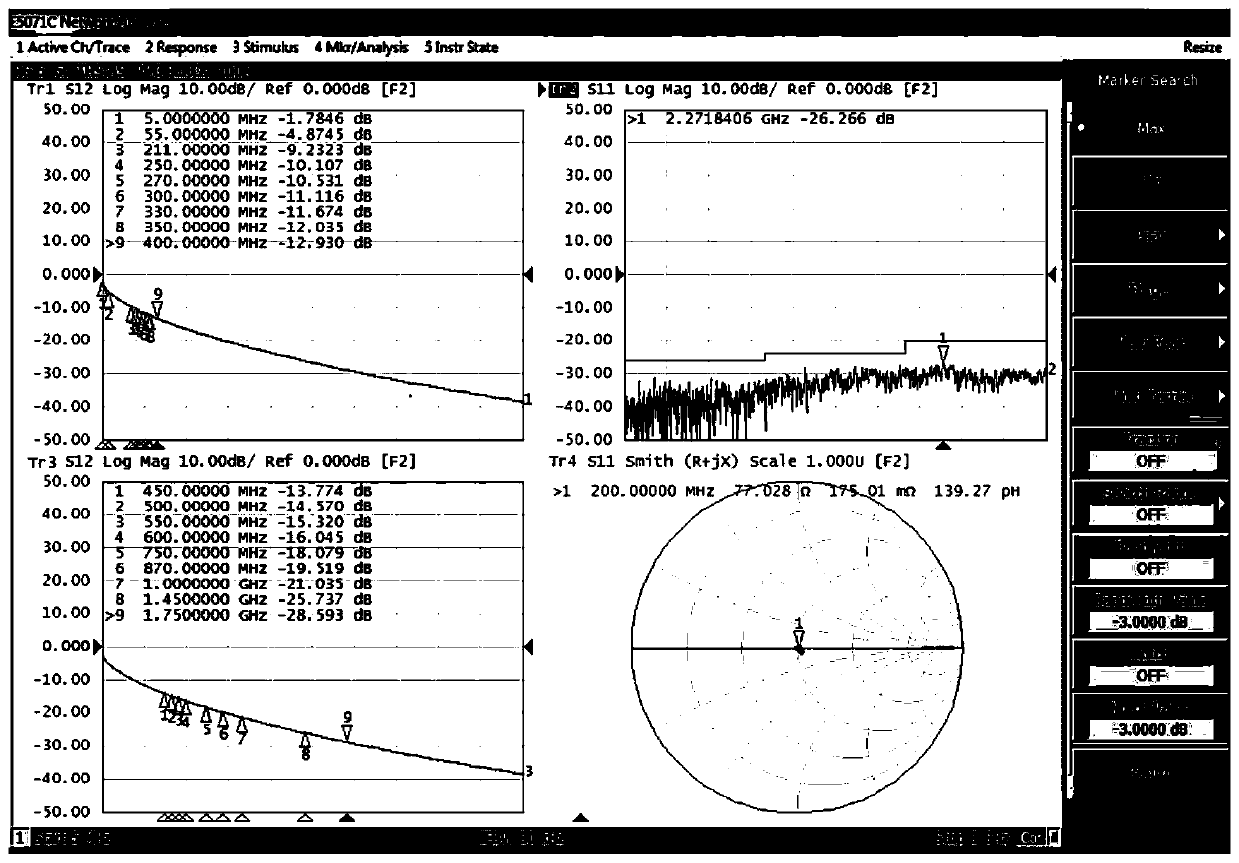

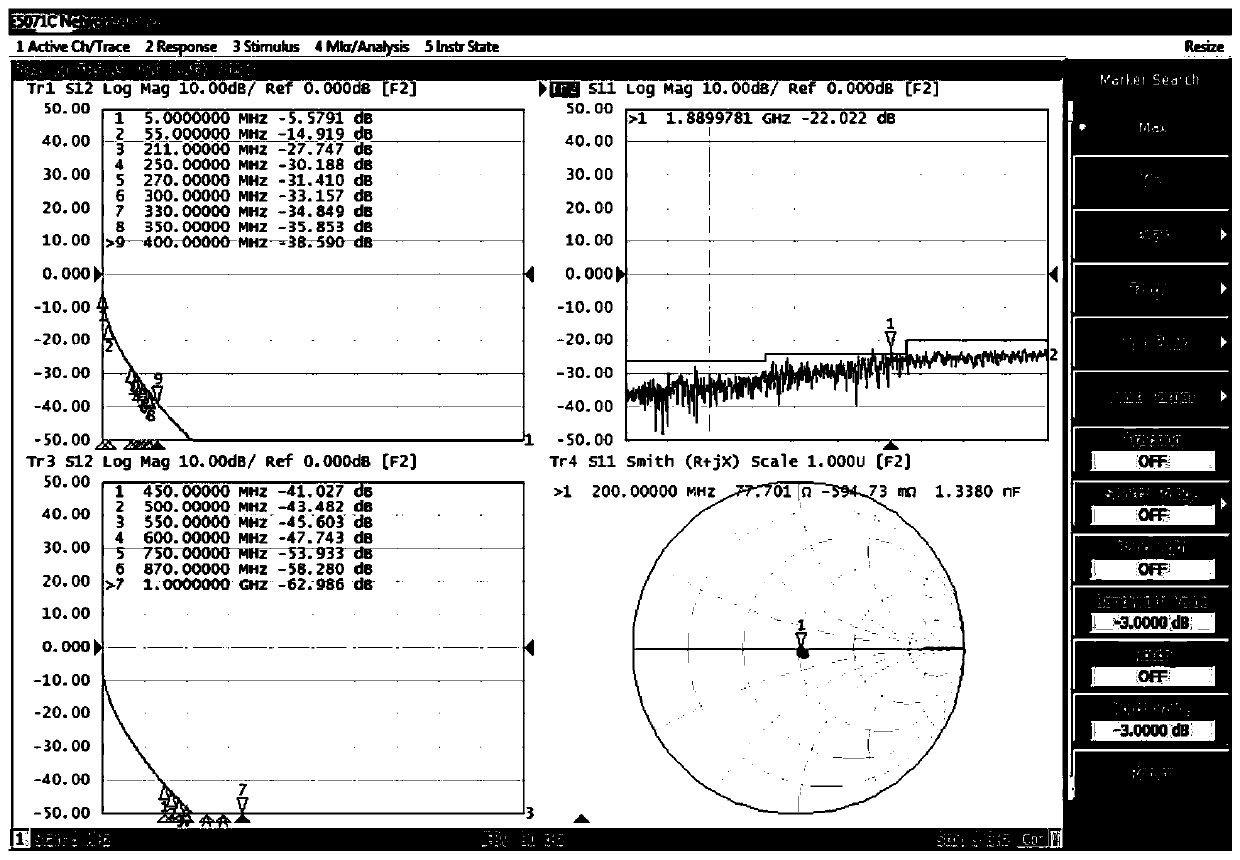

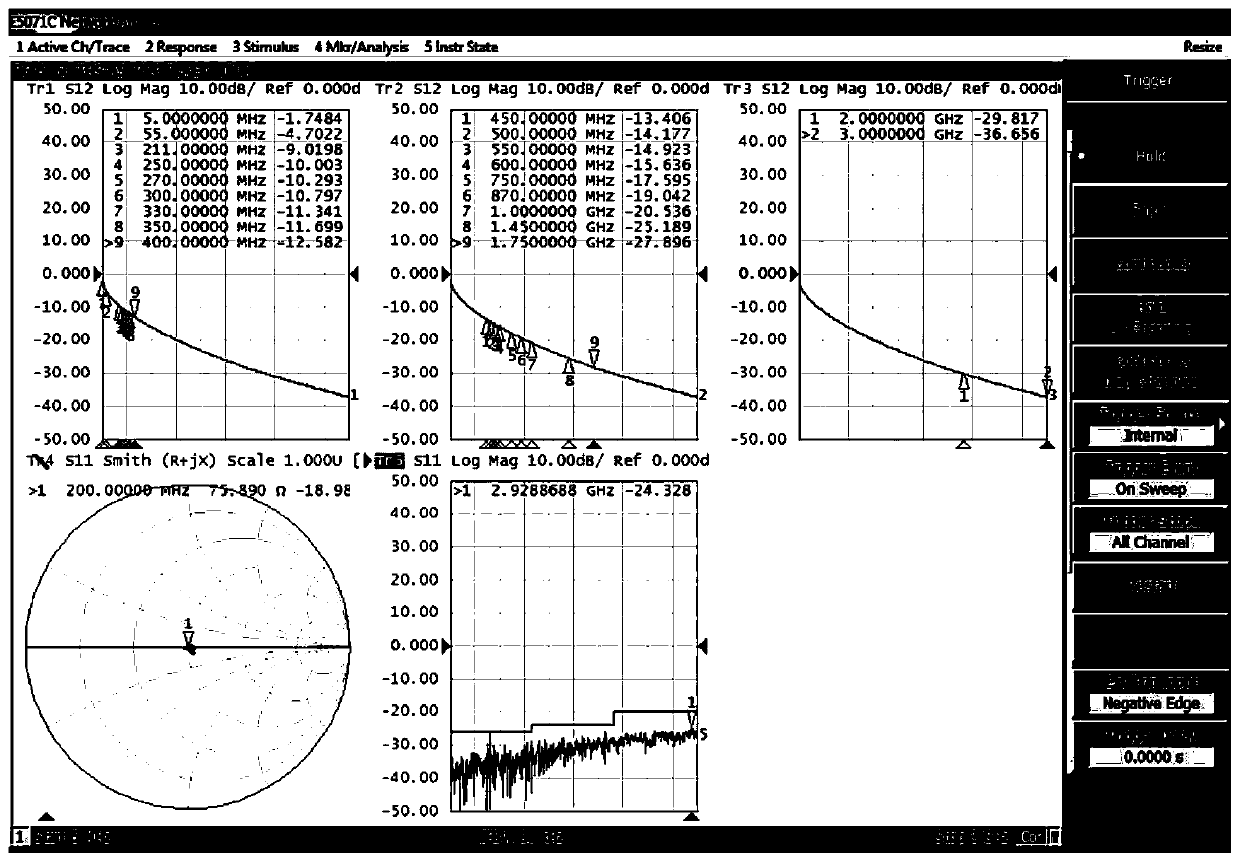

Image

Examples

Embodiment 1

[0086] An RG-6 copper-clad steel coaxial cable includes a copper-clad steel conductor, an inner skin layer, a foaming layer and an outer skin layer. In this embodiment, the diameter of the copper-clad steel conductor is 0.97 mm.

[0087] The components and parts by weight of the raw materials used to prepare the inner skin layer are shown in Table 1, and the components and parts by weight of the raw materials used to prepare the foam layer are shown in Table 2, which are used to prepare the outer skin layer The components and parts by weight of the raw materials are shown in Table 3.

[0088] A preparation method of RG-6 copper-clad steel coaxial cable, comprising the following steps:

[0089] S1. Paying off: place the copper-clad steel conductor on the pay-off frame, and pull the copper-clad steel conductor through the traction mechanism. The pulling speed is 140m / min. The heater preheats the copper-clad steel conductor, and the preheating temperature is 40°C.

[0090] S2....

Embodiment 2

[0106] An RG-6 copper-clad steel coaxial cable includes a copper-clad steel conductor, an inner skin layer, a foaming layer and an outer skin layer.

[0107] A preparation method of an RG-6 copper-clad steel coaxial cable, the difference from Example 1 is that the components and parts by weight of the raw materials used to prepare the inner skin layer are shown in Table 1, and are used to prepare foamed The components and parts by weight of the raw materials of the layer are shown in Table 2, and the components and parts by weight of the raw materials used to prepare the skin layer are shown in Table 3.

[0108] The diameter of the copper clad steel conductor is 1.02mm.

[0109] In the method for preparing the RG-6 copper-clad steel coaxial cable, the pulling speed in step S1 is 150m / min.

[0110] The preheating temperature in step S1 is 50°C.

[0111] The stirring time of steps S2-S4 is 8 minutes for forward rotation and 8 minutes for reverse rotation.

[0112] The adhesio...

Embodiment 3

[0119] An RG-6 copper-clad steel coaxial cable includes a copper-clad steel conductor, an inner skin layer, a foaming layer and an outer skin layer.

[0120] A method for preparing an RG-6 copper-clad steel coaxial cable, the difference from Example 1 is that the components and parts by weight of the raw materials used to prepare the inner skin layer are as shown in Table 1, and are used to prepare foamed The components and parts by weight of the raw materials of the layer are shown in Table 2, and the components and parts by weight of the raw materials used to prepare the skin layer are shown in Table 3.

[0121] The diameter of the copper clad steel conductor is 1.07mm.

[0122] In the method for preparing the RG-6 copper-clad steel coaxial cable, the pulling speed in step S1 is 160m / min.

[0123] The preheating temperature in step S1 is 60°C.

[0124] The stirring time of steps S2-S4 is 10 min for forward rotation and 10 min for reverse rotation.

[0125] The adhesion be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com